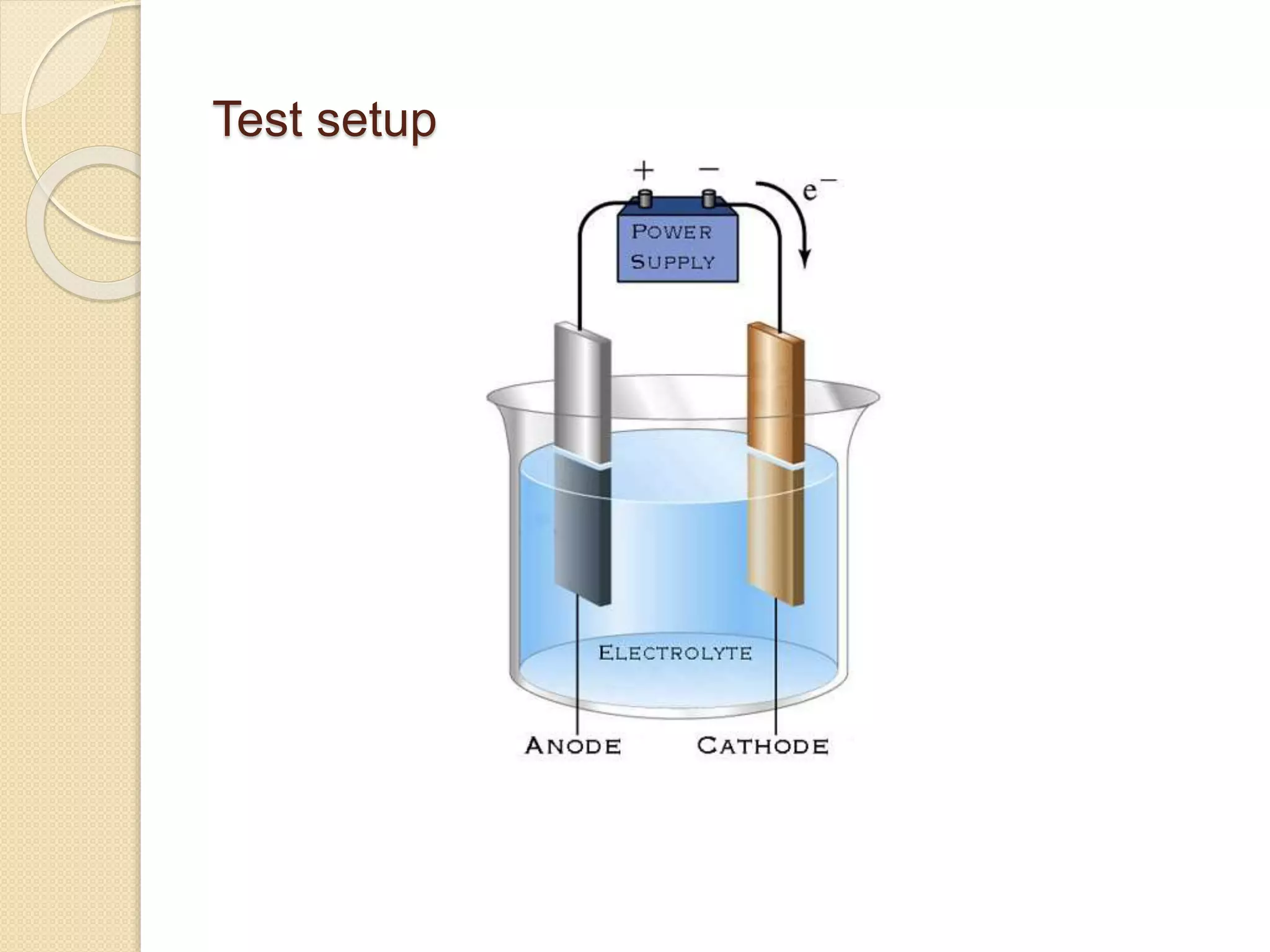

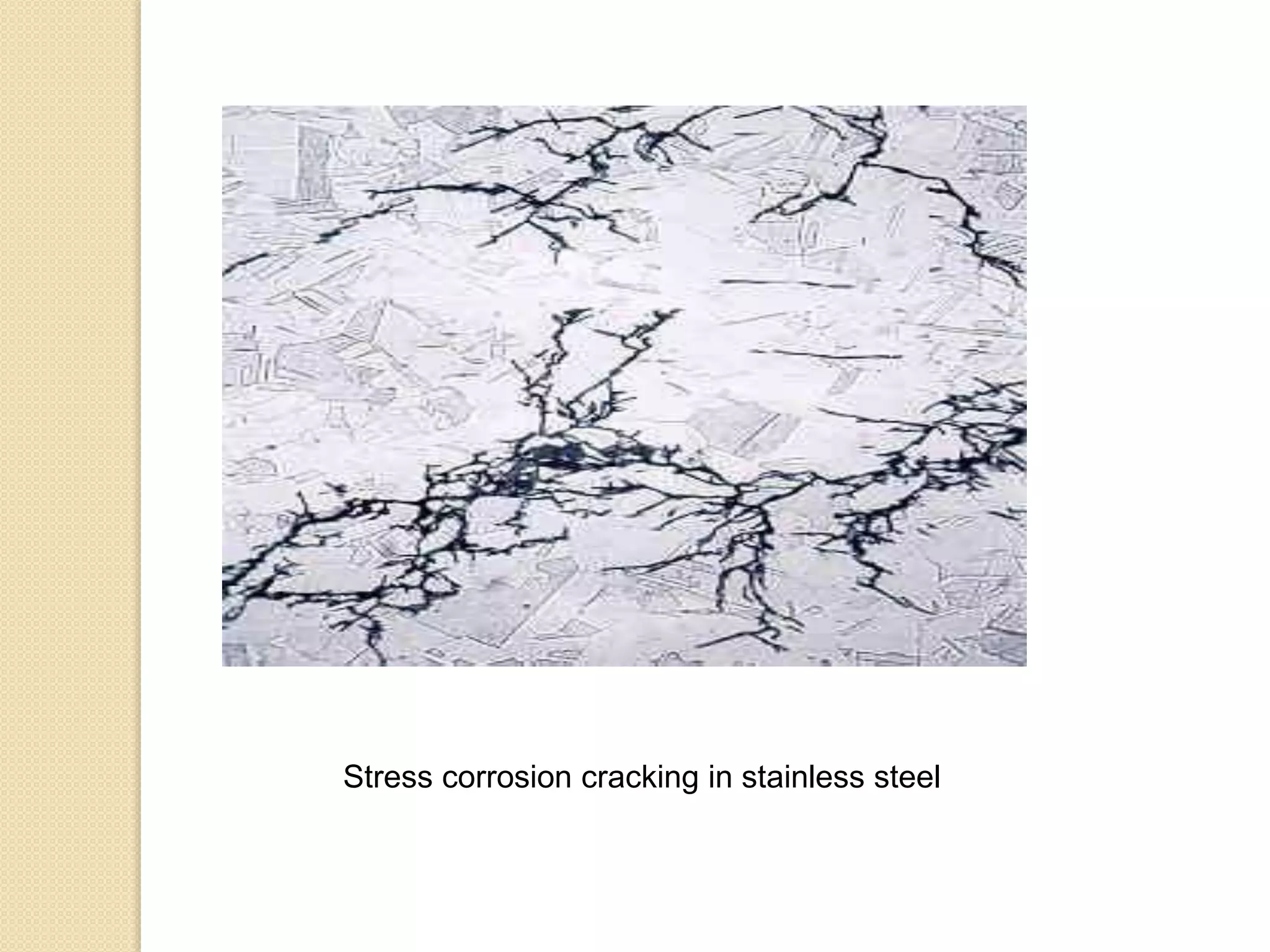

The document discusses various tests used to evaluate susceptibility to intergranular corrosion and stress corrosion cracking. It describes the oxalic etch test, Streicher test, Huey test, and Strauss test which are used to test for intergranular corrosion. The constant stress test, fracture mechanics test, and slow strain rate test are also outlined to evaluate stress corrosion cracking susceptibility. The tests involve subjecting metal samples to corrosive environments and acids while applying stress or strain and analyzing for cracking or corrosion.