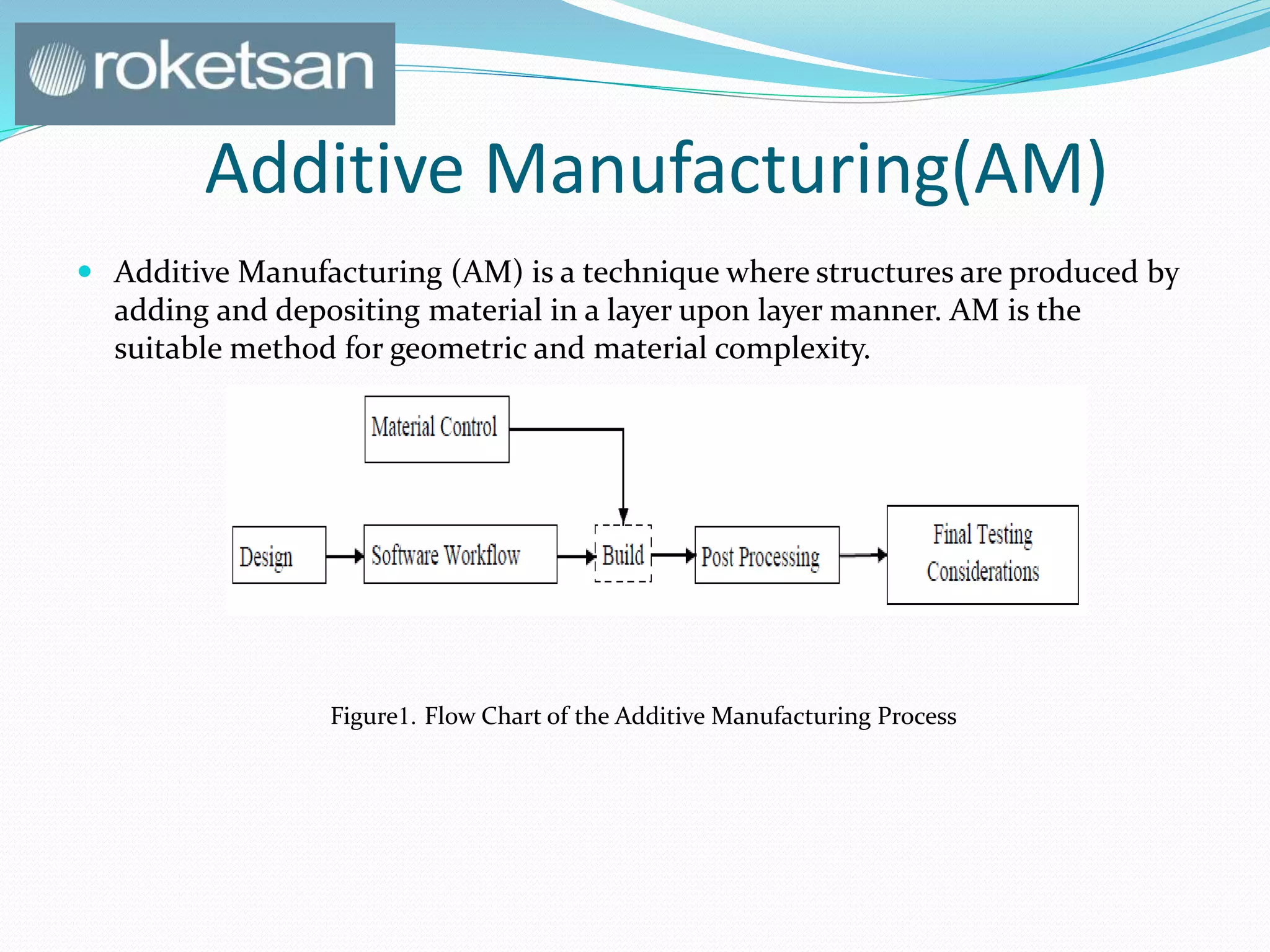

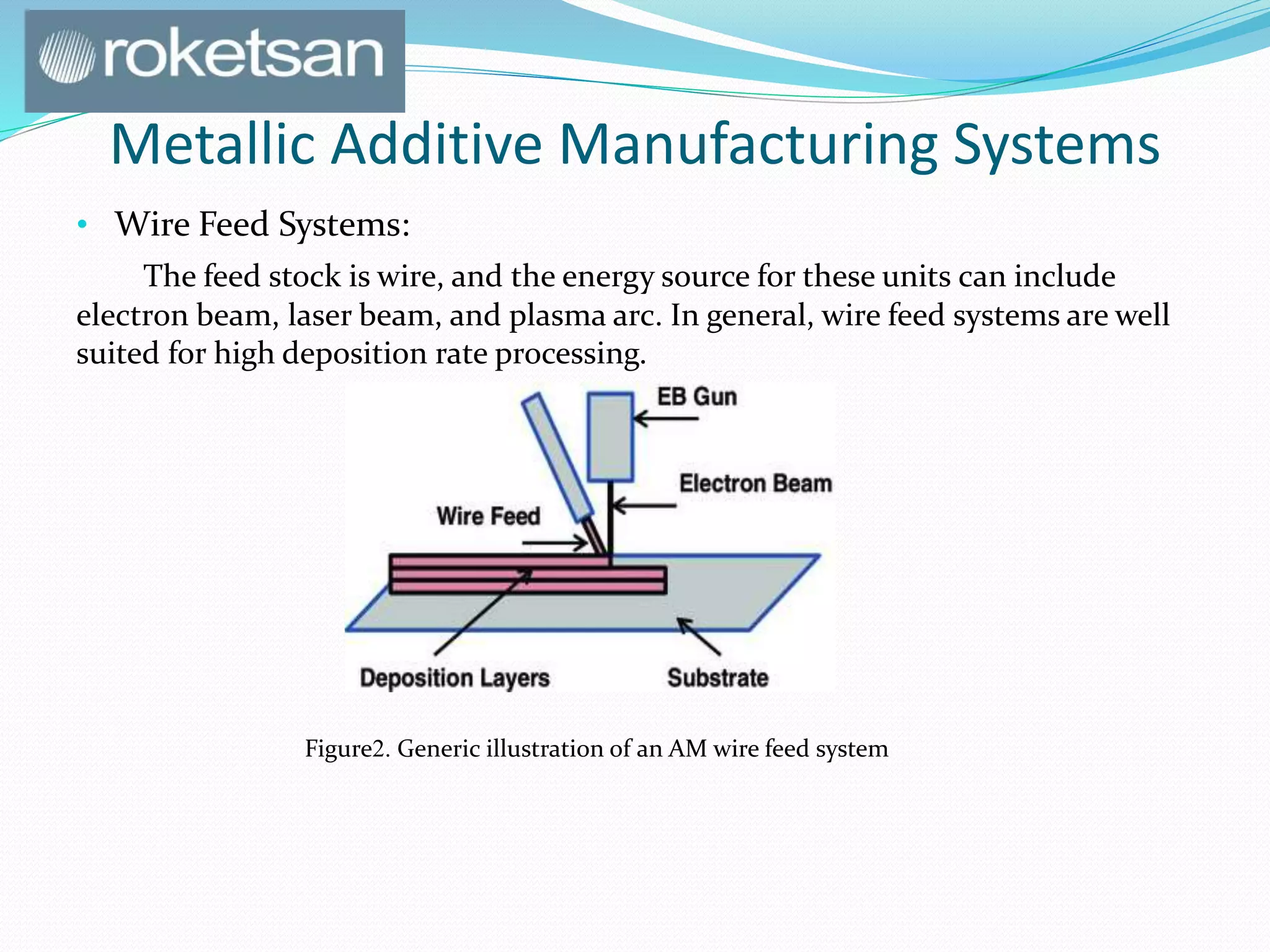

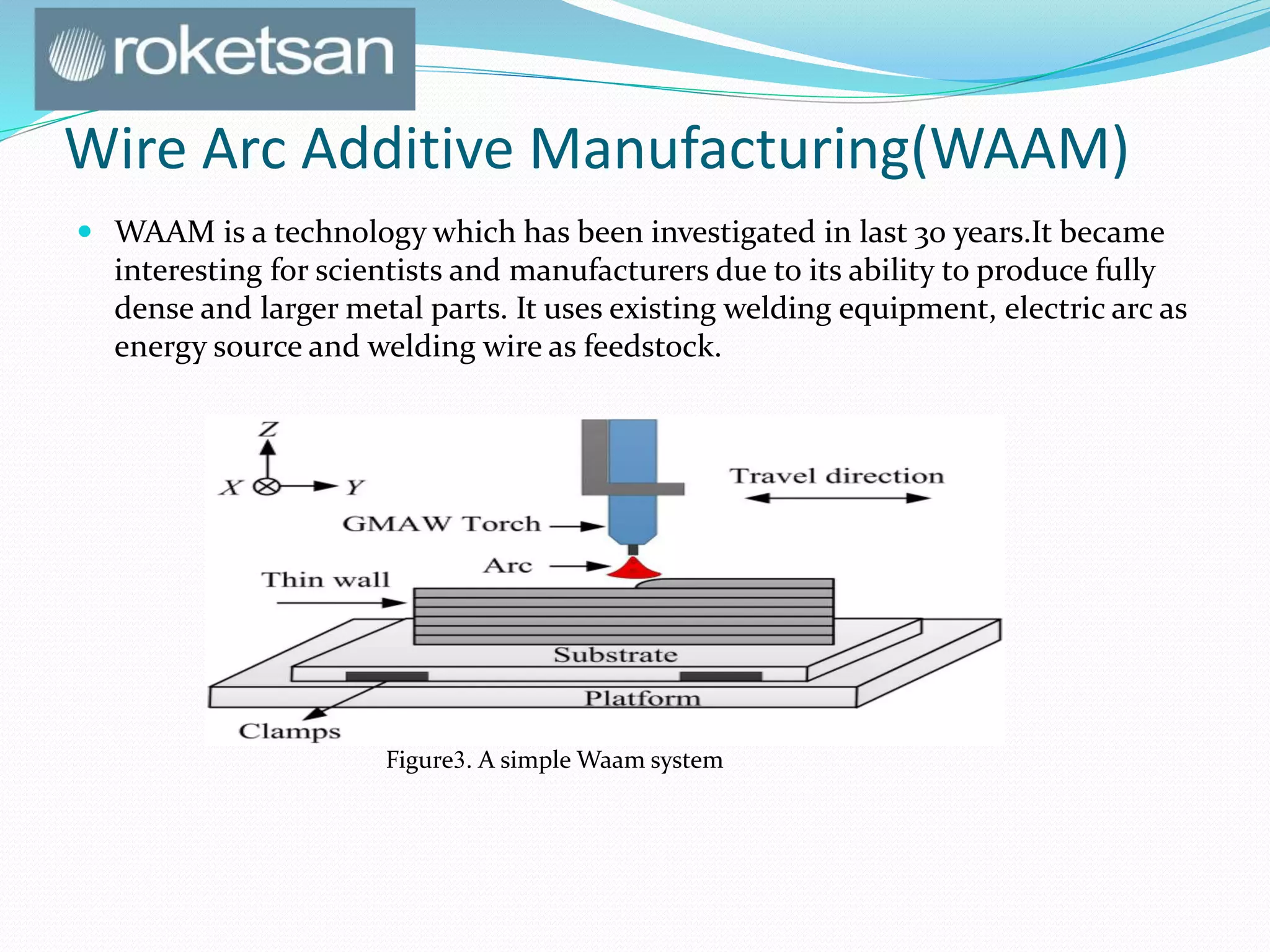

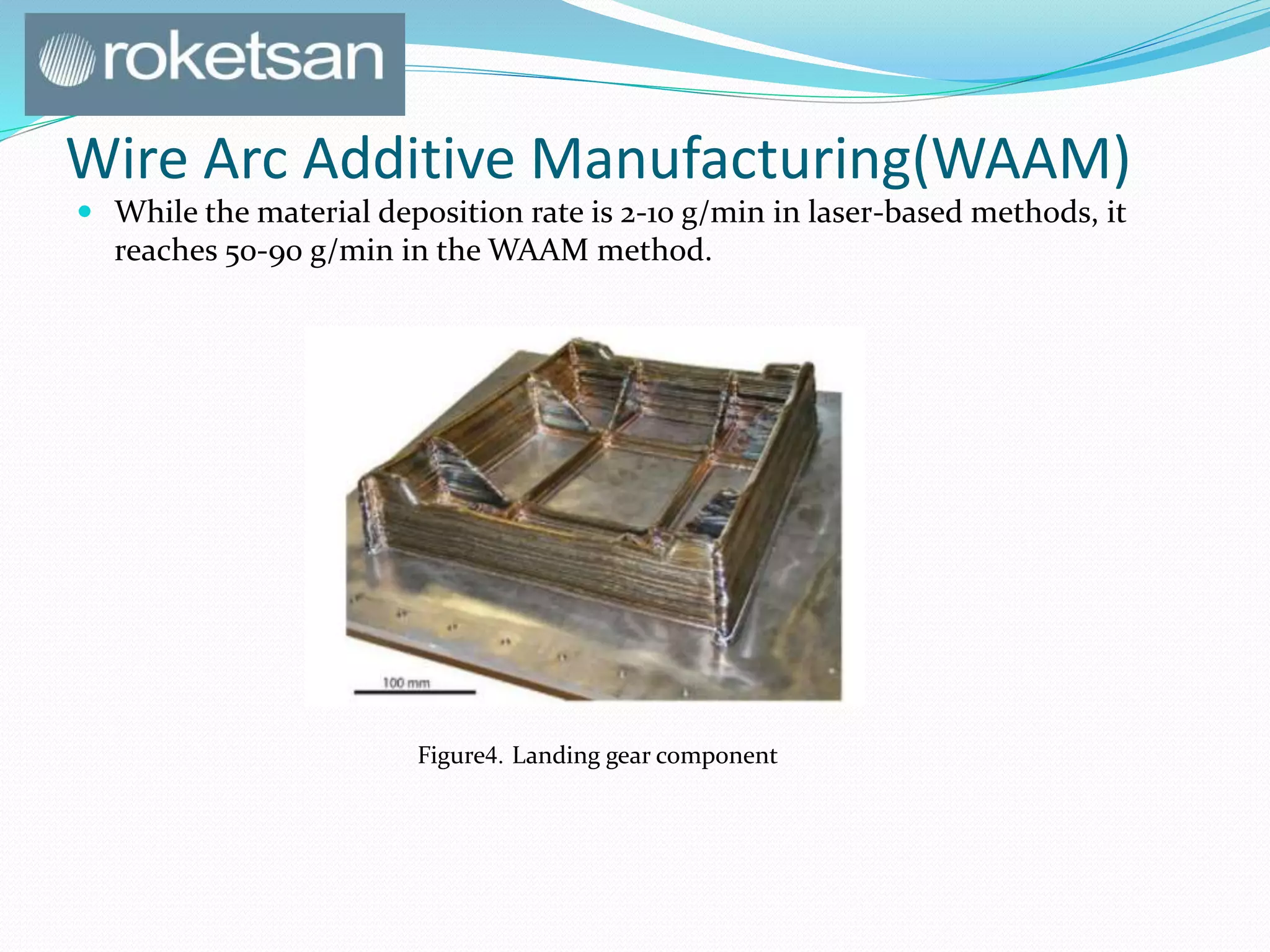

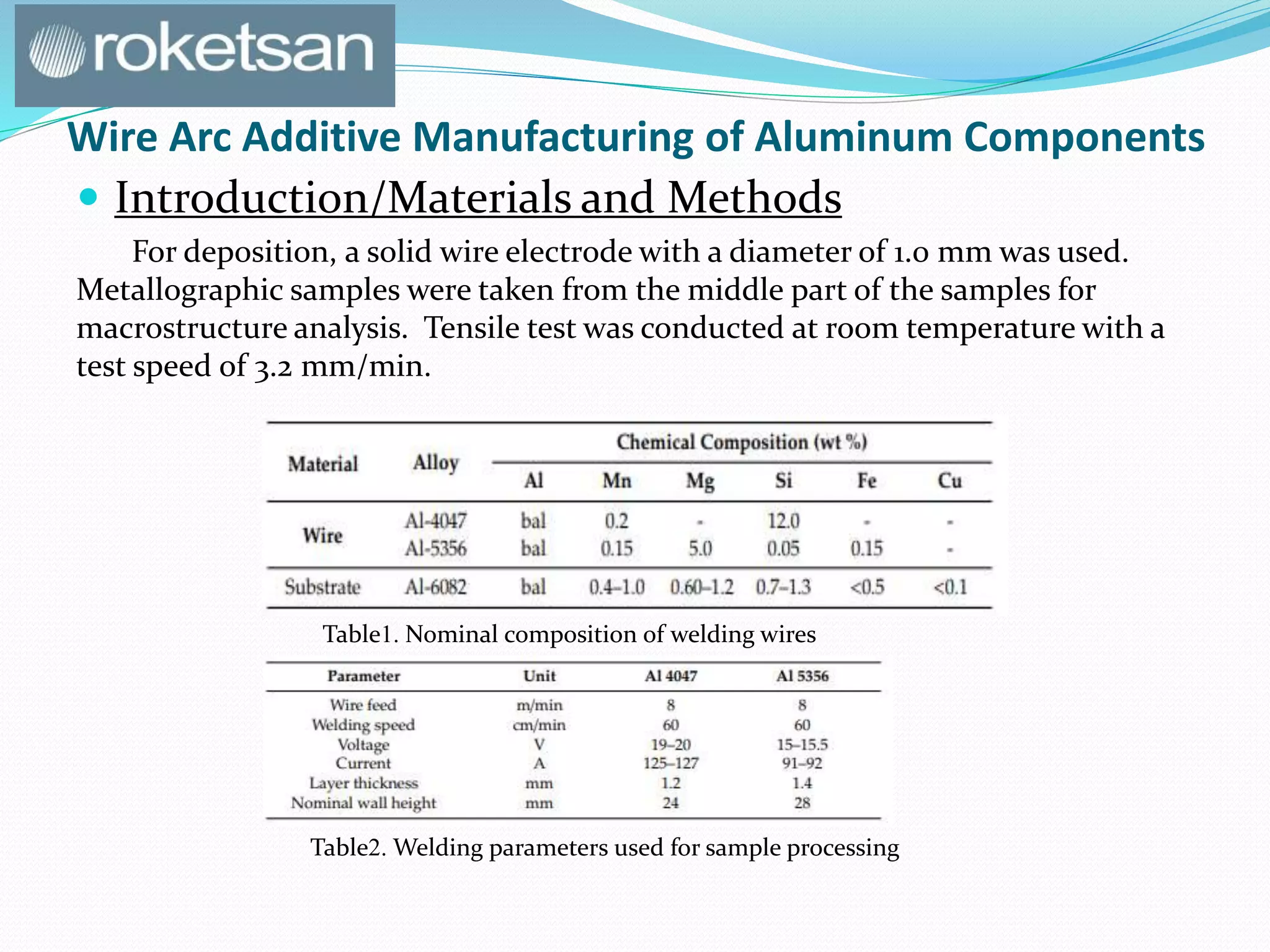

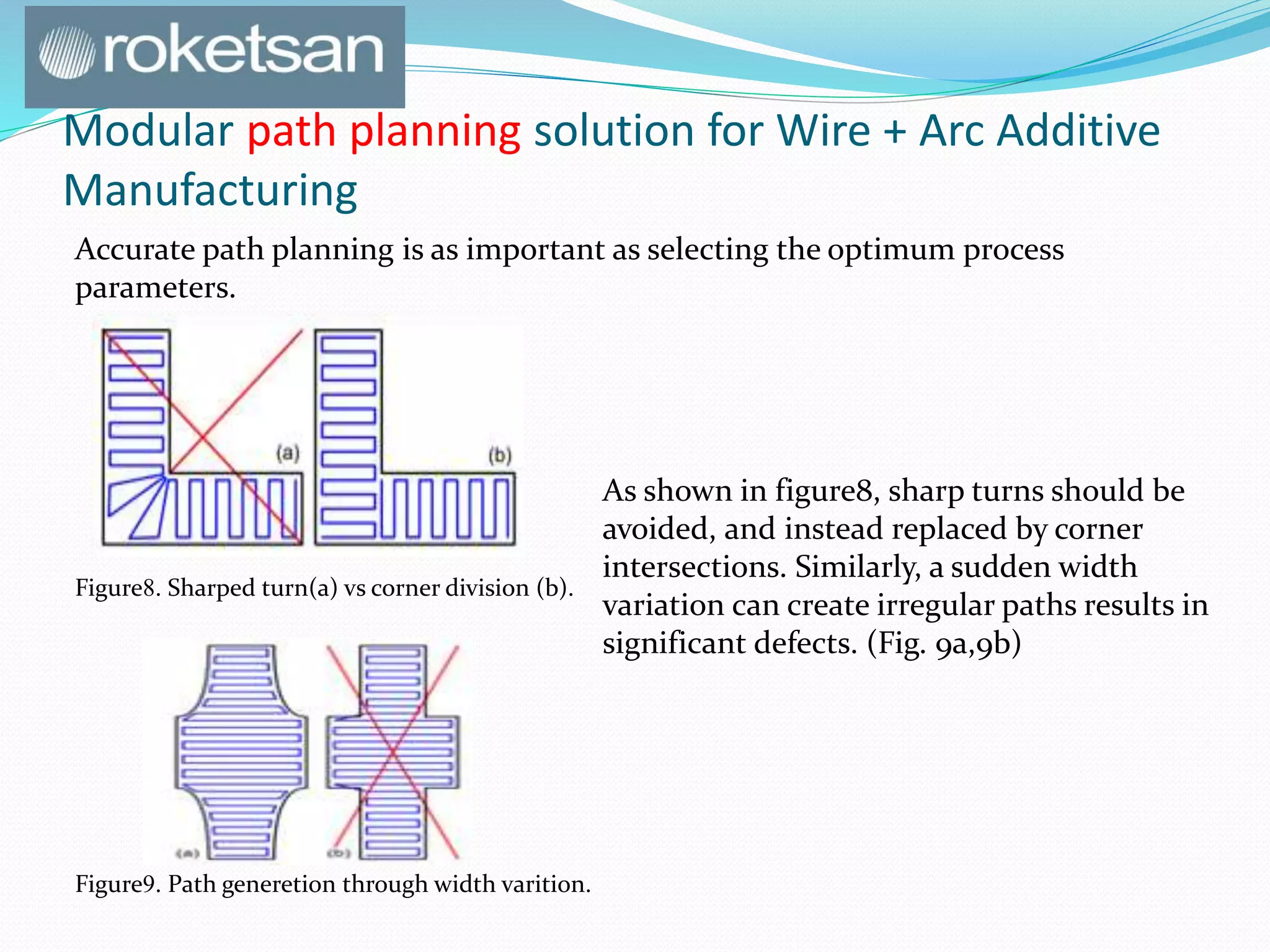

This document provides an overview of Wire Arc Additive Manufacturing (WAAM). It describes WAAM as an additive manufacturing technique that uses an electric arc as an energy source and welding wire as a feedstock. WAAM allows for high deposition rates compared to powder-based methods. The document reviews academic studies on WAAM of aluminum components and modular path planning. It also discusses applications of WAAM in aerospace and comparisons between WAAM and powder laser melting methods.