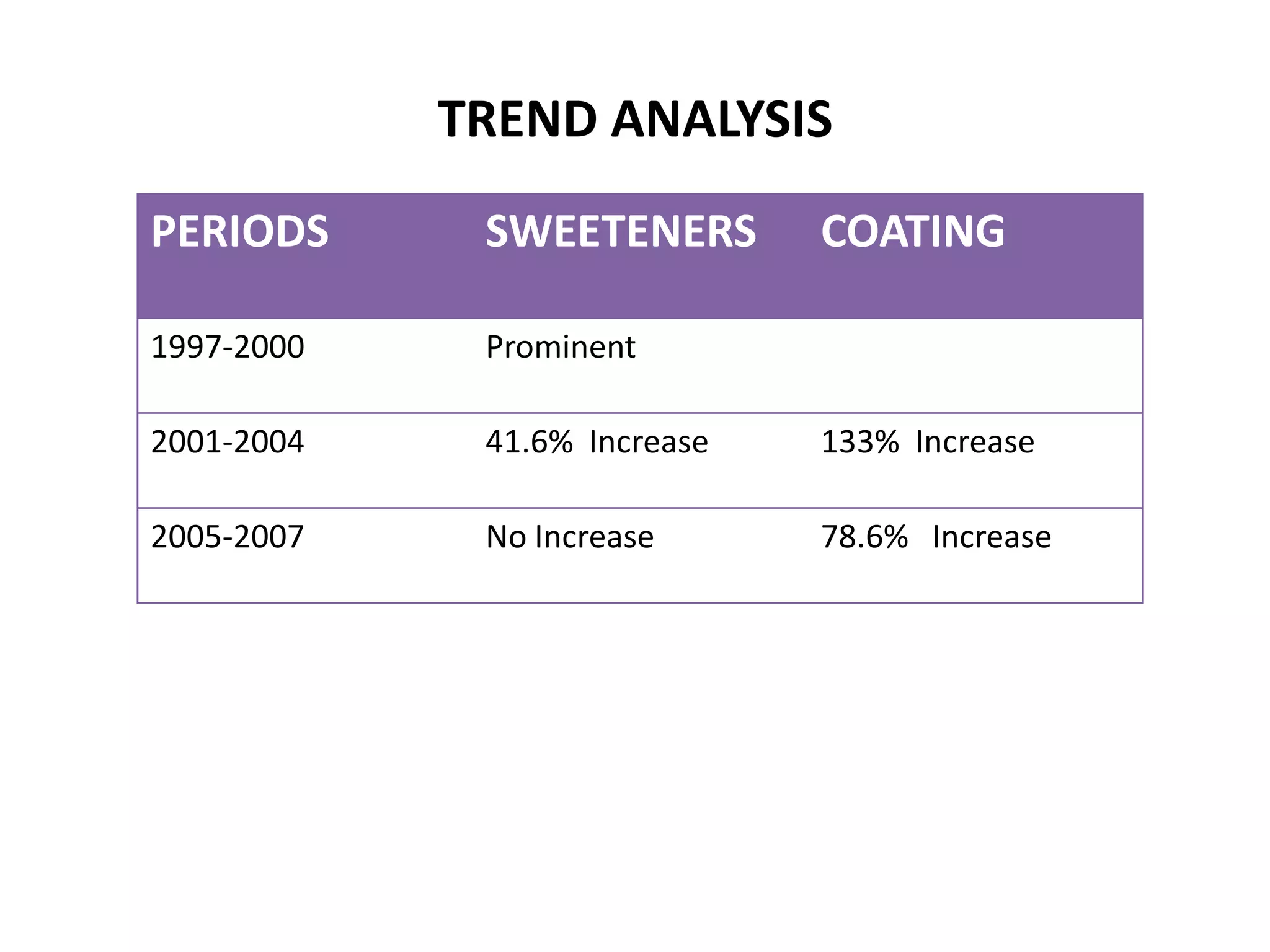

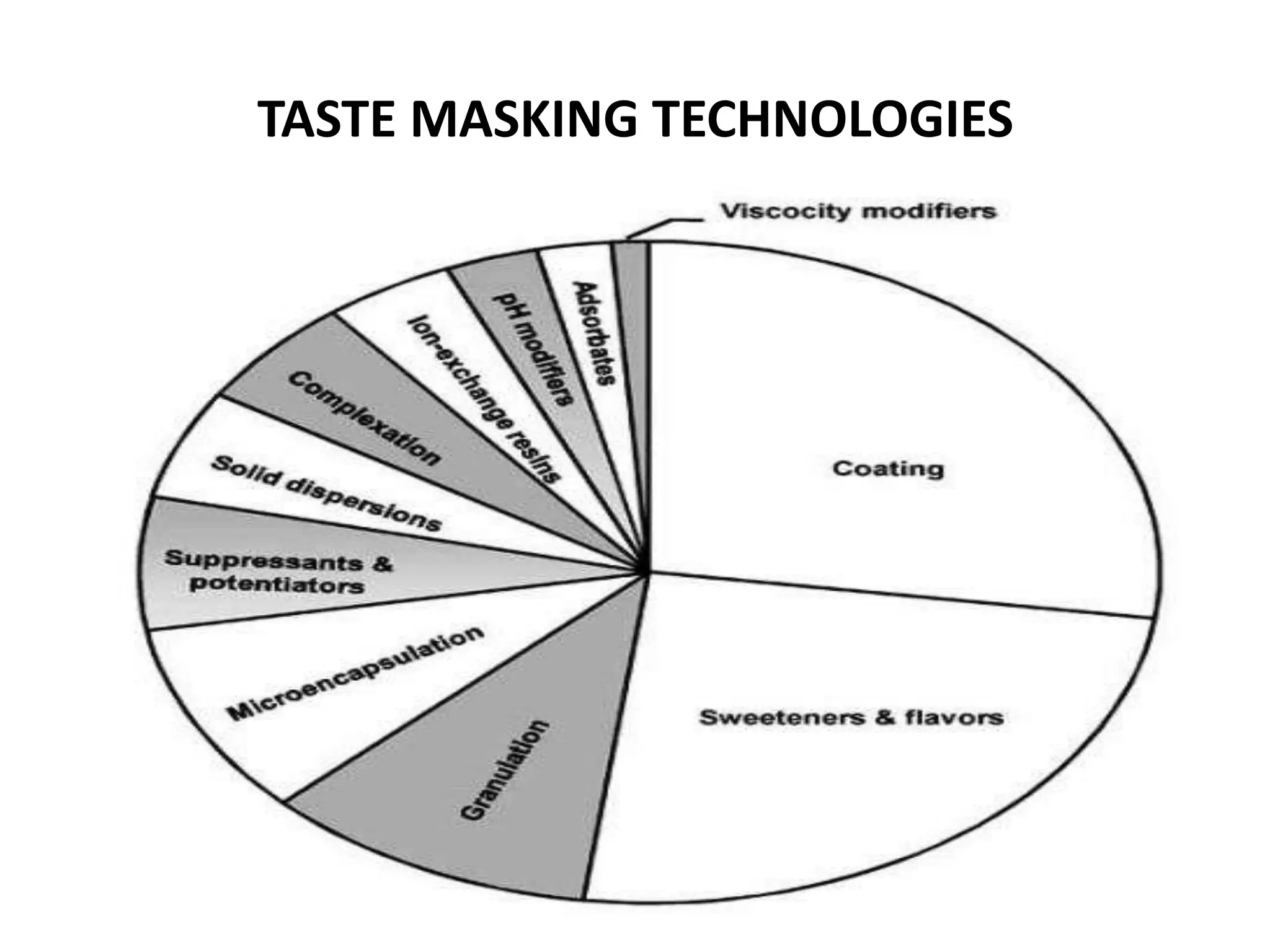

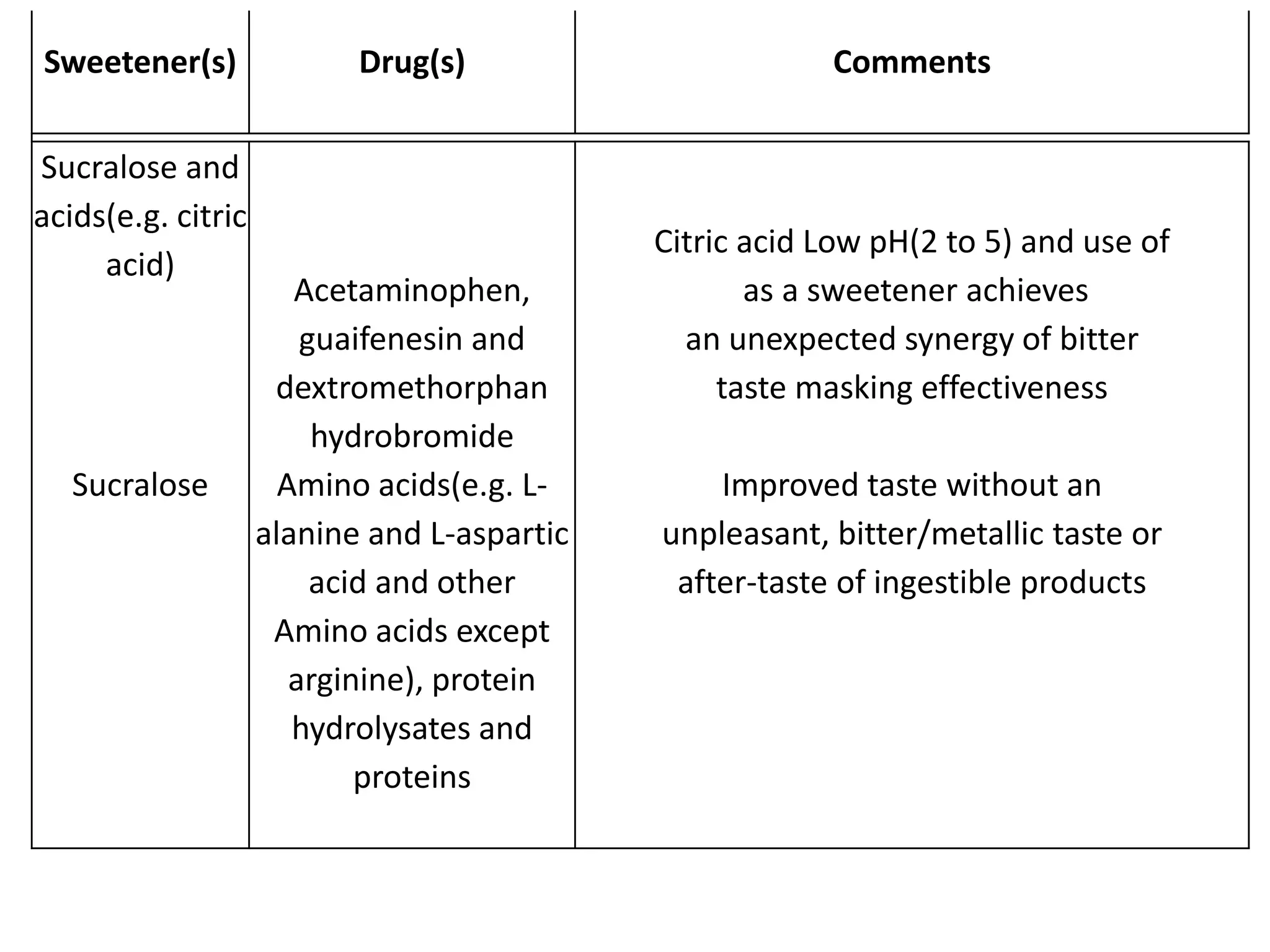

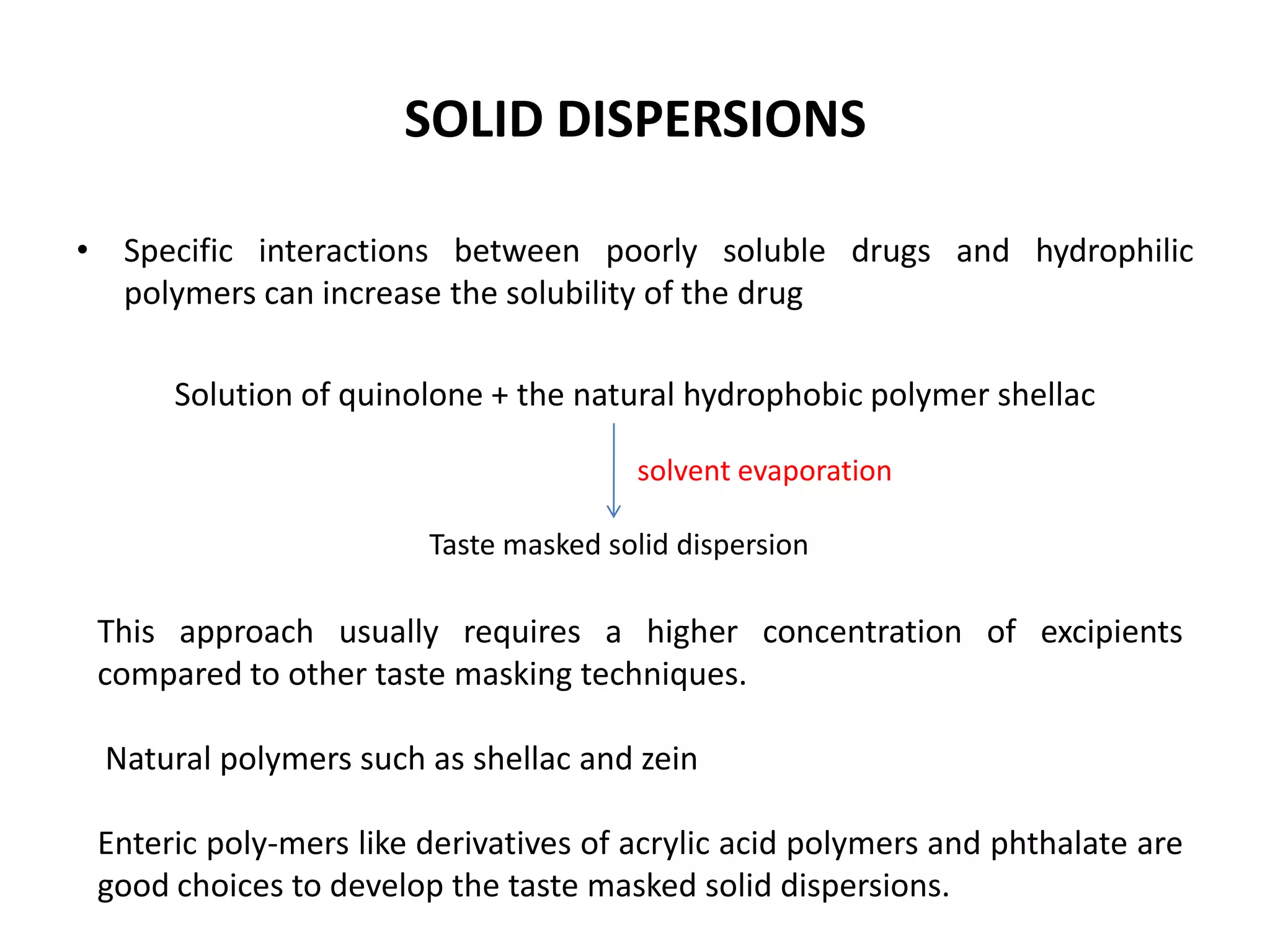

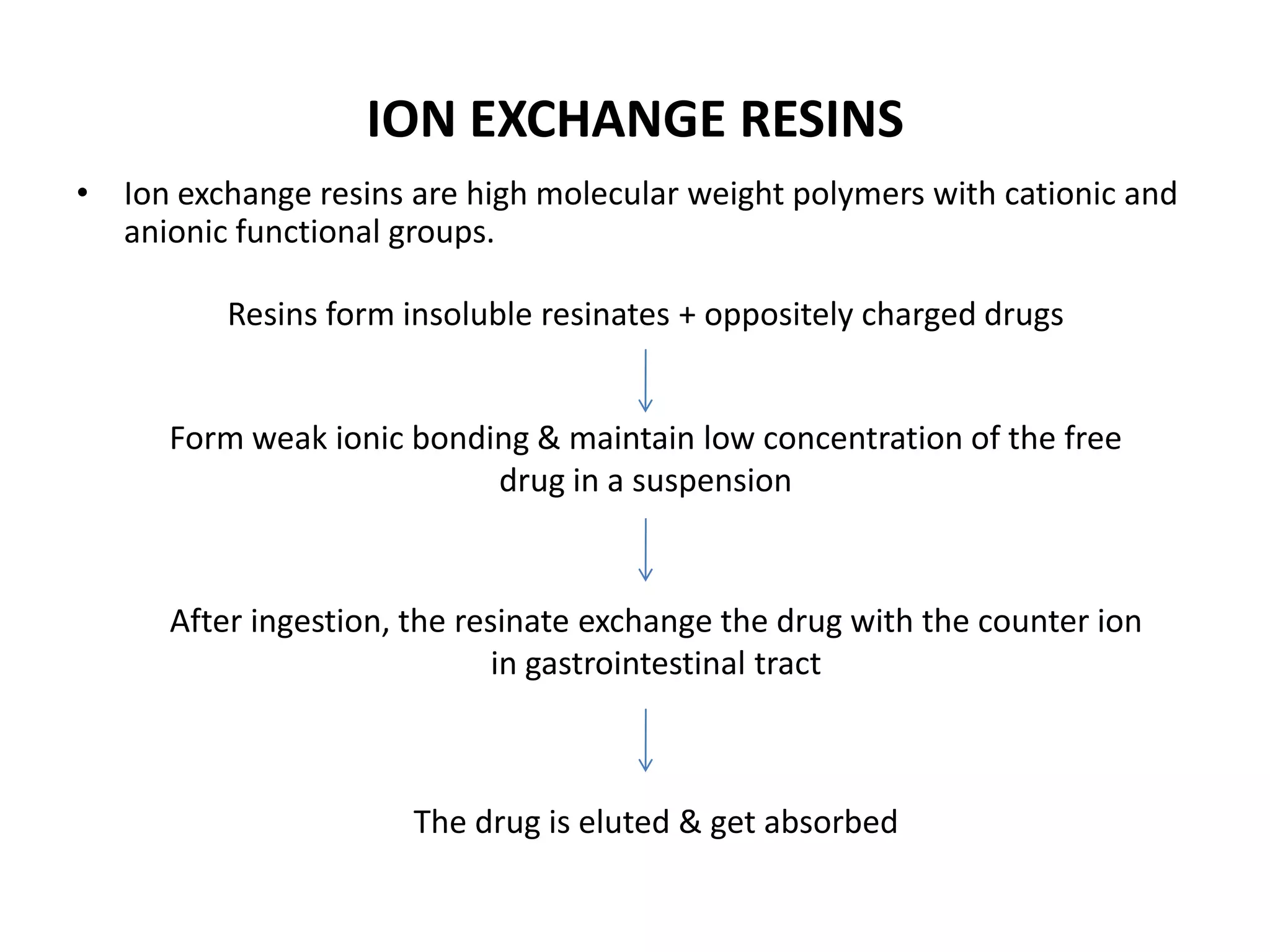

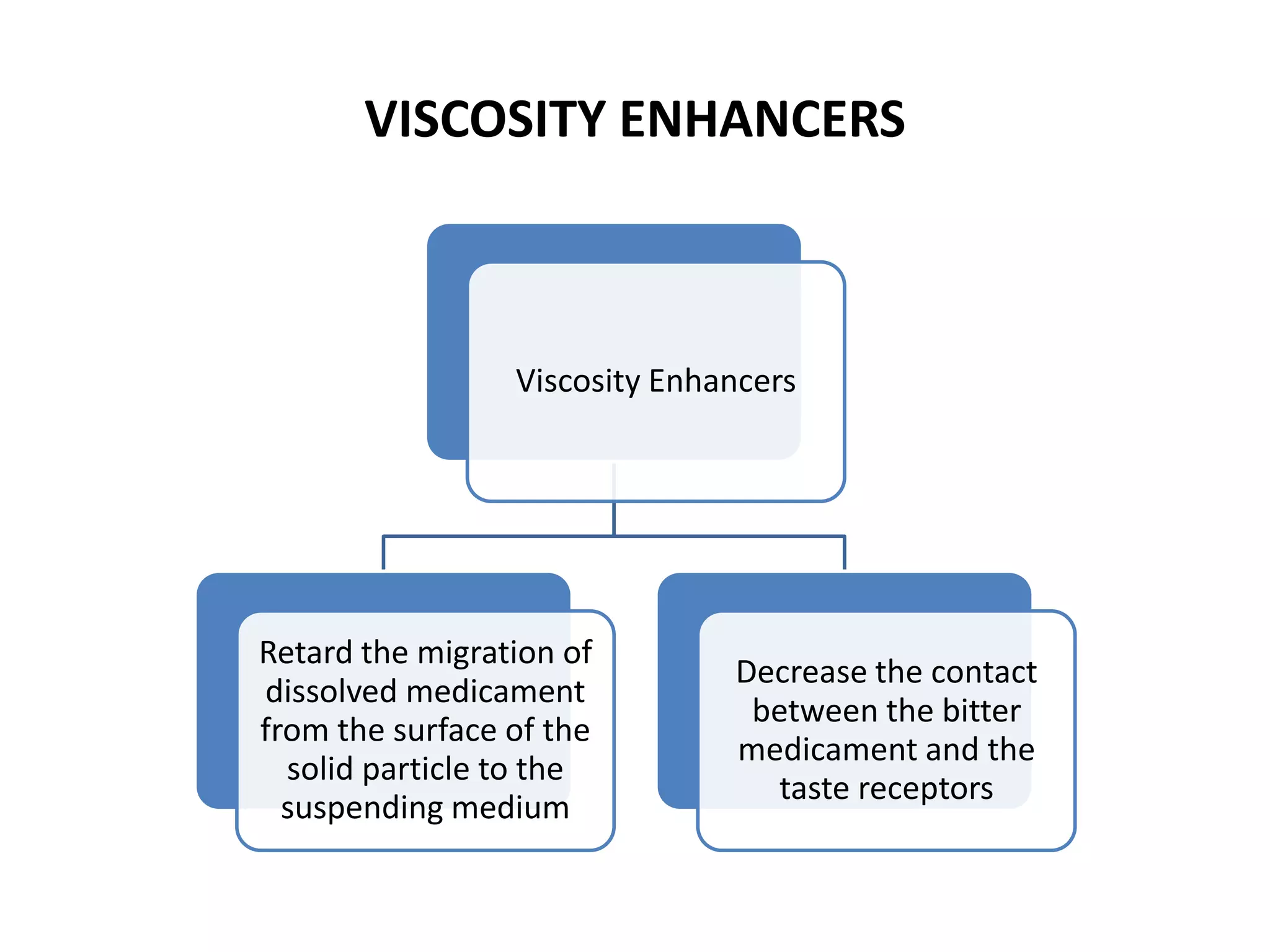

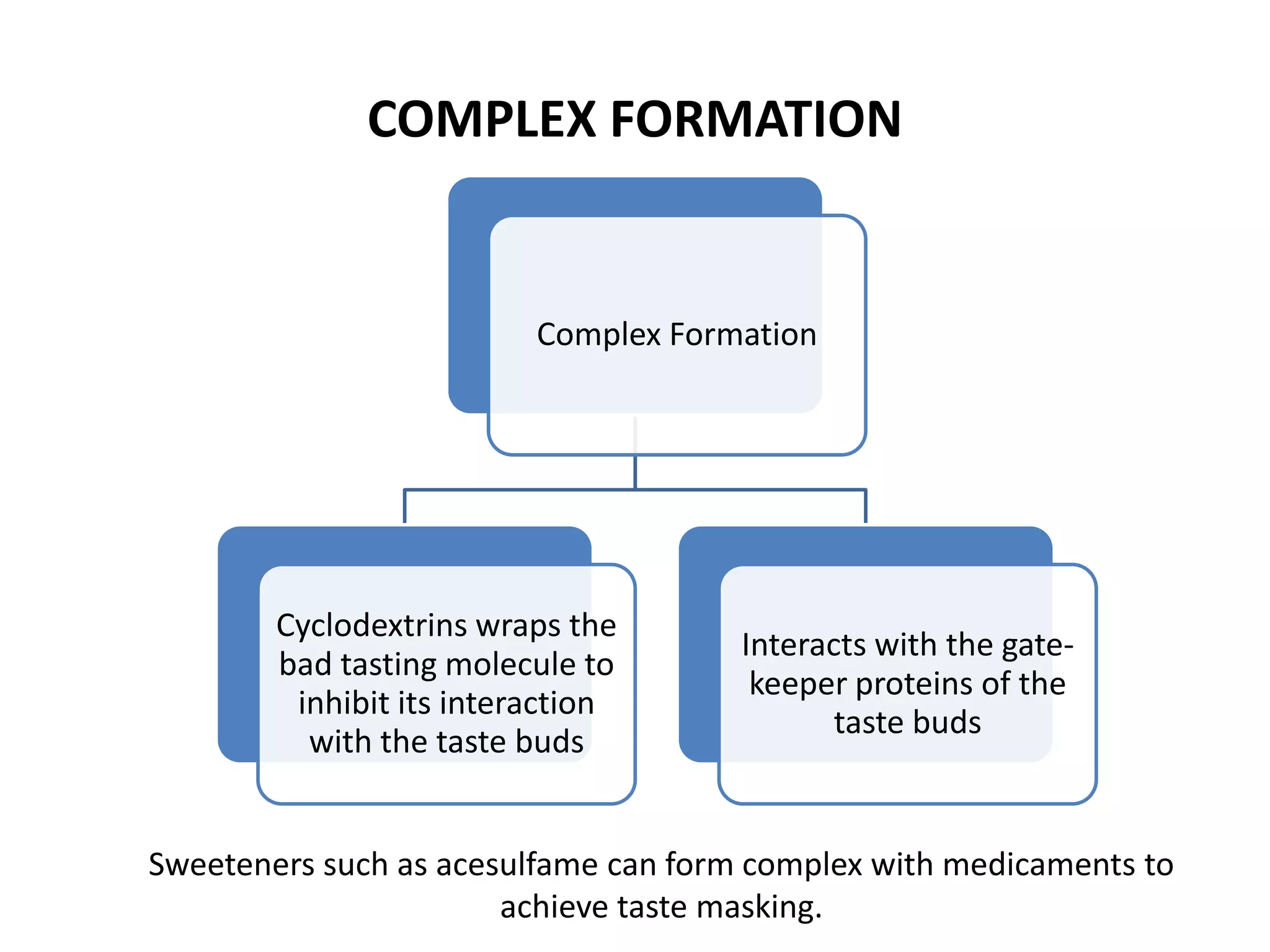

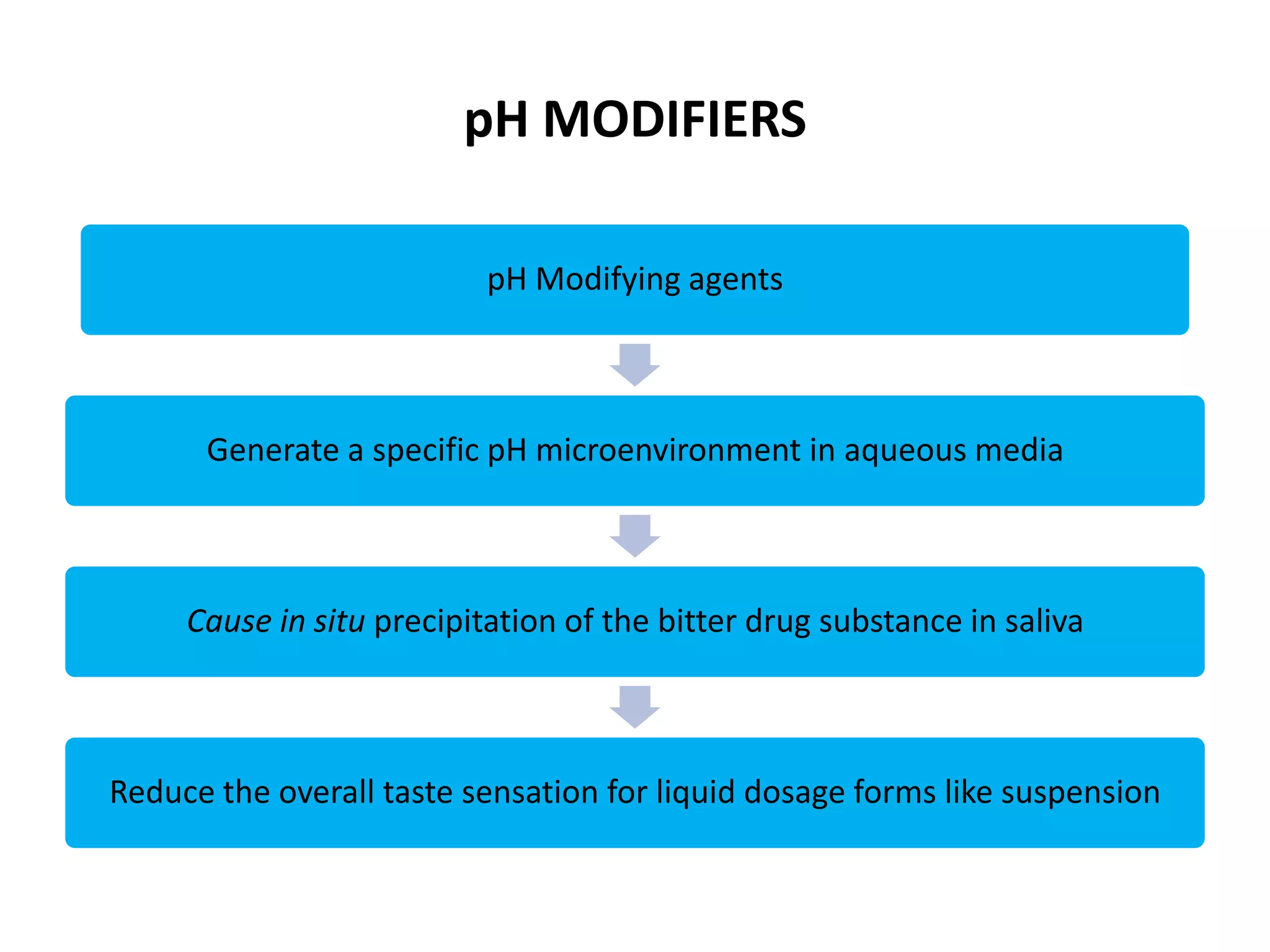

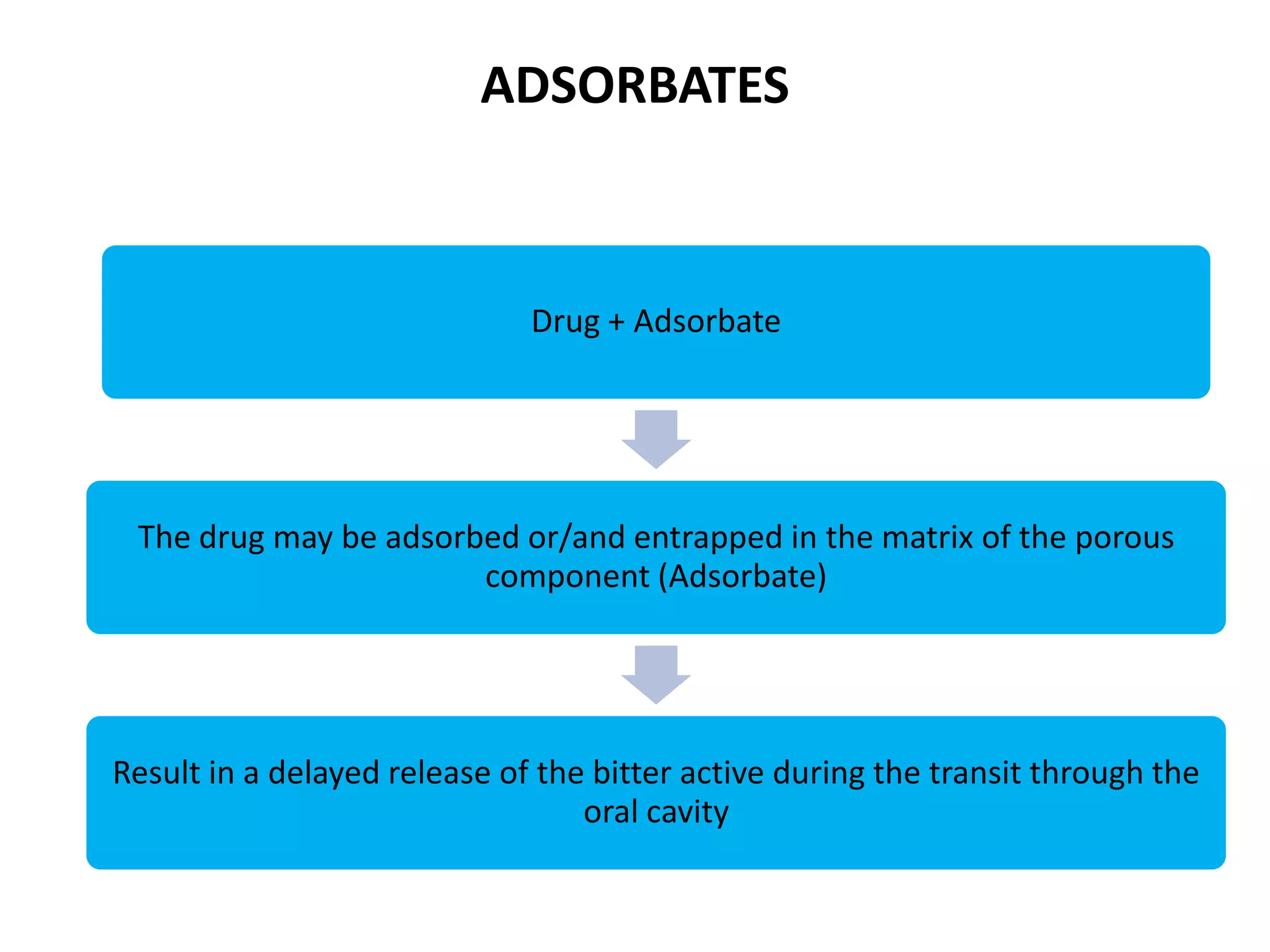

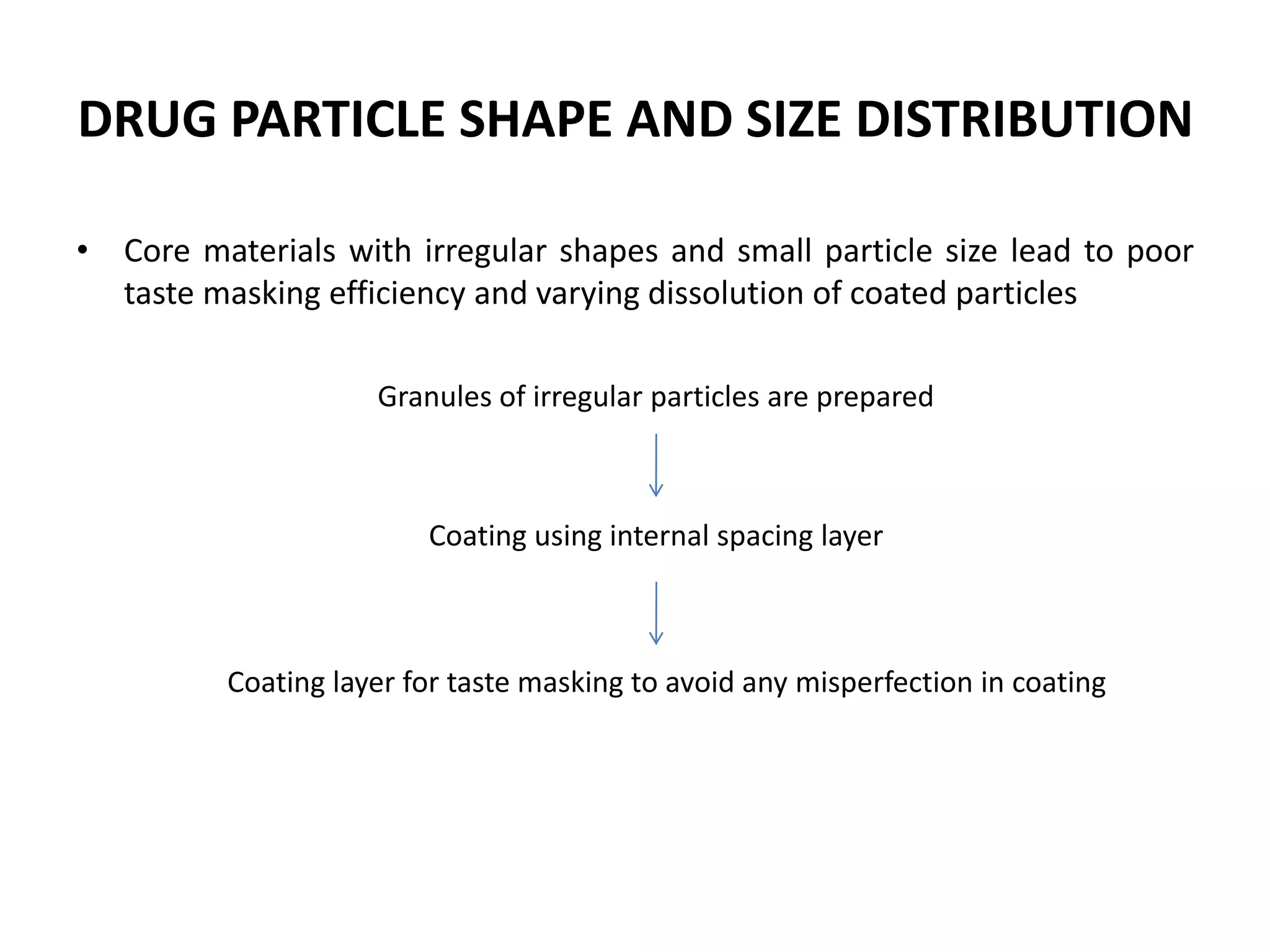

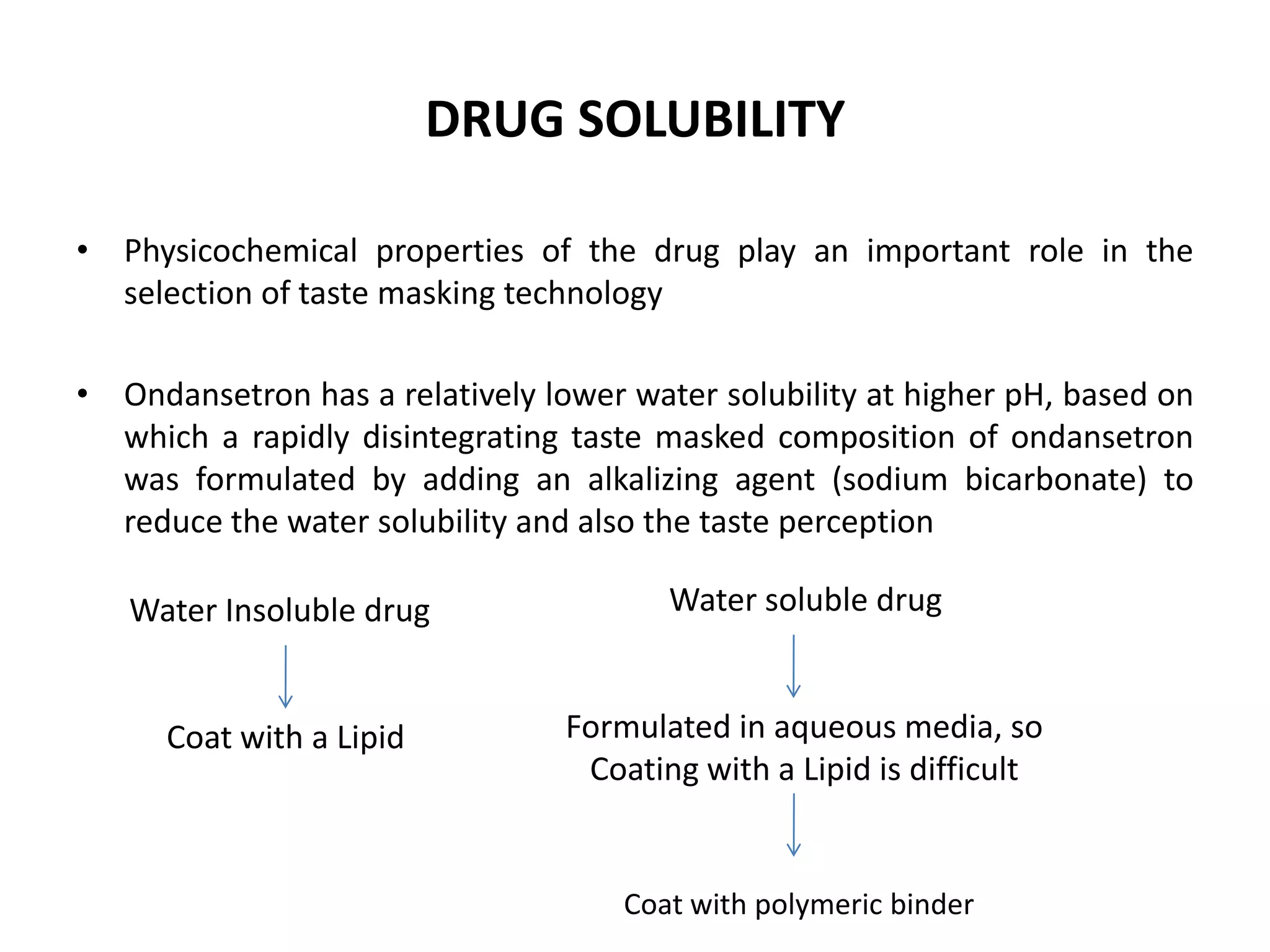

The document reviews trends in taste masking technologies for pharmaceuticals, focusing on patents from 1997 to 2007. It discusses various methods such as coating, microencapsulation, granulation, and the use of sweeteners to improve the palatability of bitter medications. Additionally, it highlights the challenges of taste masking for different drug formulations and provides insights on the selection of appropriate masking strategies based on the drug's characteristics.