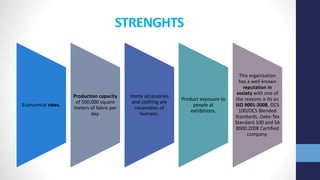

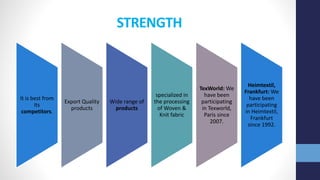

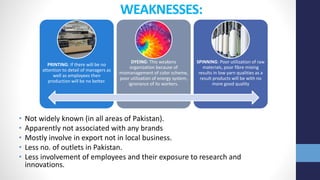

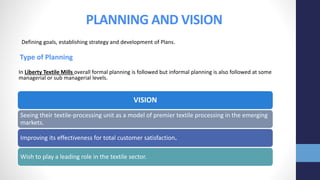

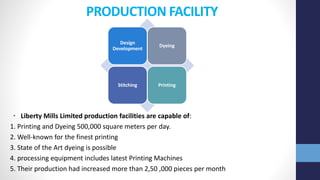

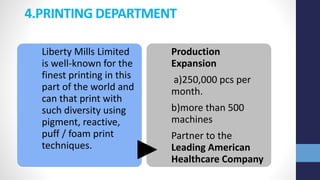

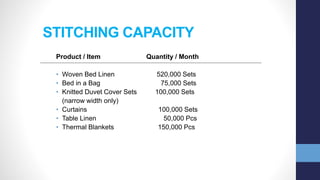

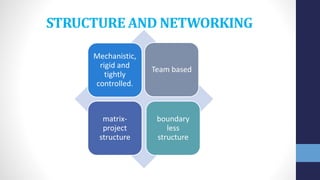

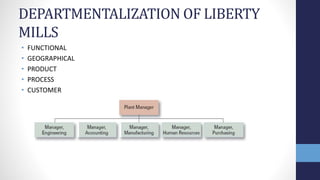

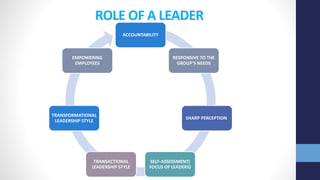

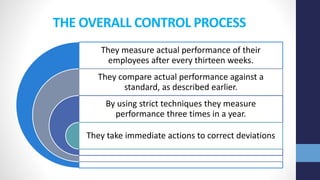

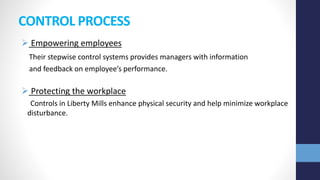

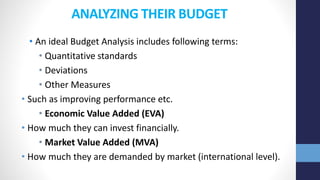

This document provides an overview of Liberty Mills Limited, a textile processing and production company in Karachi, Pakistan. It discusses the company's introduction, SWOT analysis, planning, organizing, leading, and controlling functions. Some key points include that Liberty Mills was established in 1964, has a production capacity of 500,000 square meters per day, and follows principles of management in most departments. It also obtains various certifications and participates in international textile exhibitions.