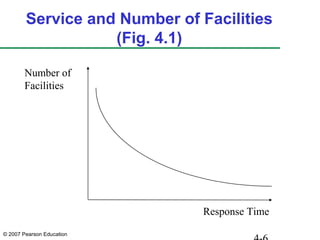

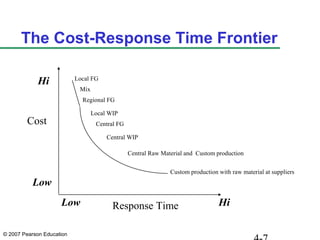

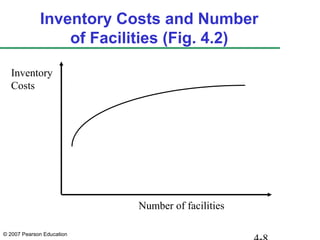

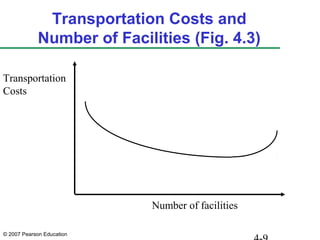

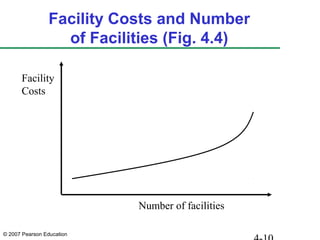

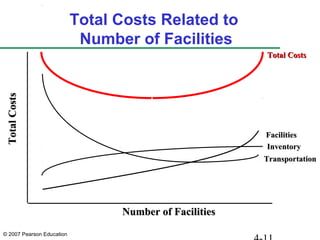

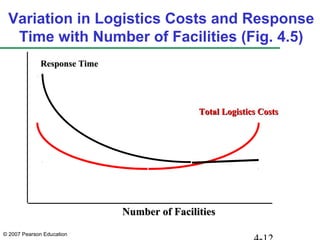

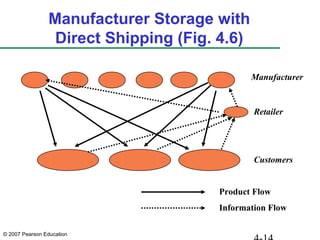

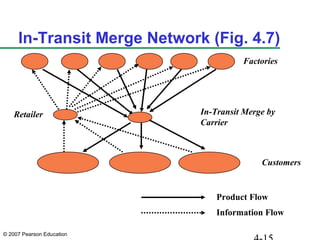

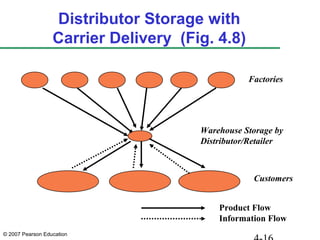

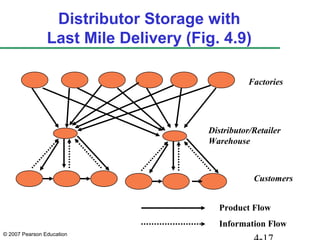

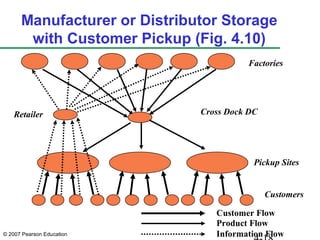

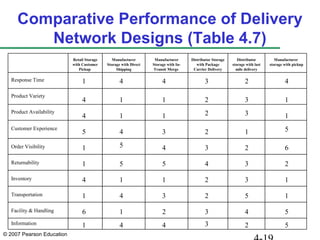

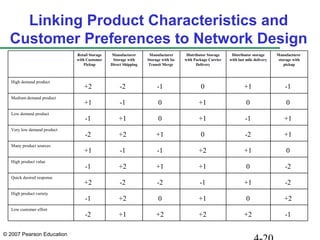

This document discusses factors that influence distribution network design, including customer needs, costs, and various design options. Distribution directly impacts costs and customer experience. The number of facilities in a network affects response time, inventory levels, transportation and facility costs. Design options include direct shipping from manufacturers, distributor warehouses, retail stores, and mixed approaches. E-business is changing distribution's impact on customer service and costs. The type of network chosen has long-term consequences for the supply chain.