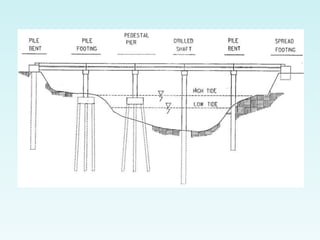

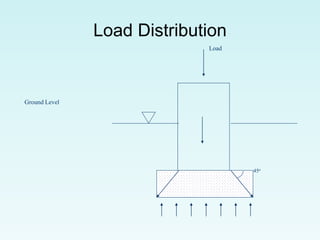

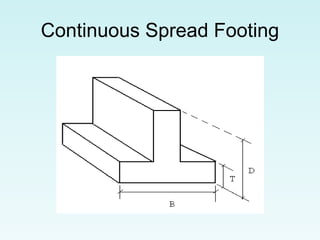

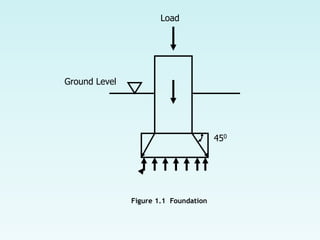

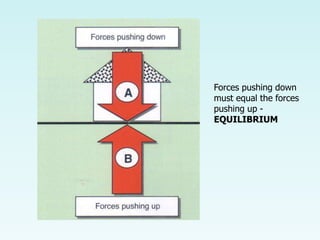

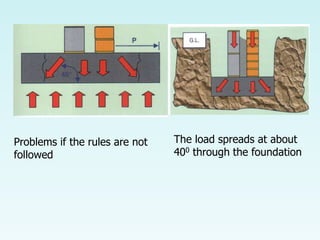

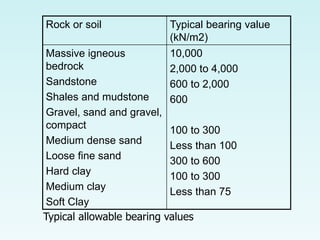

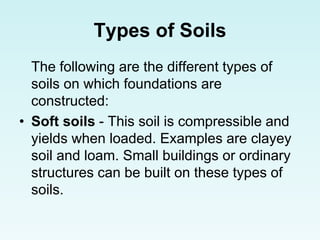

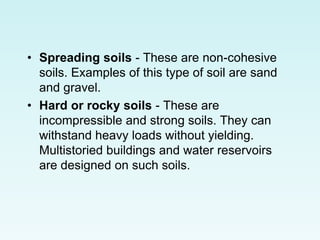

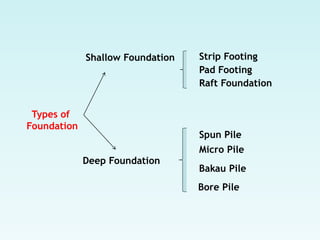

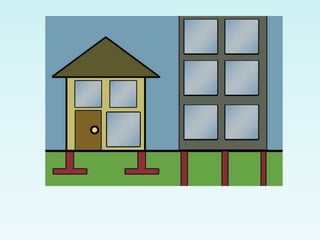

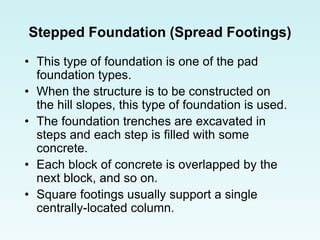

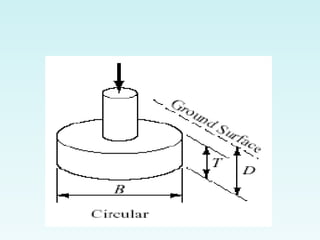

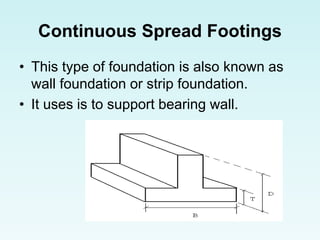

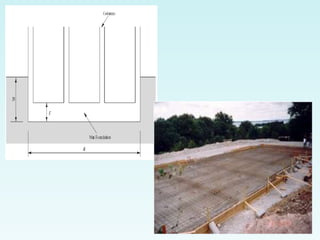

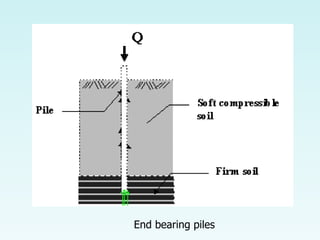

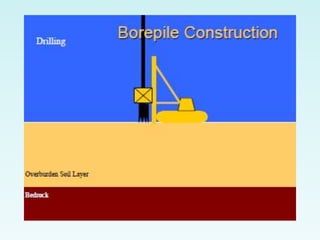

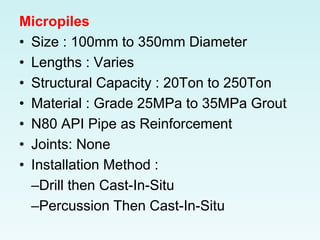

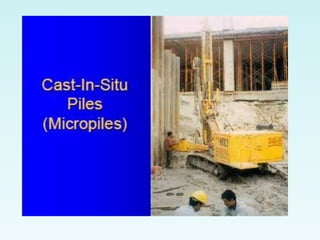

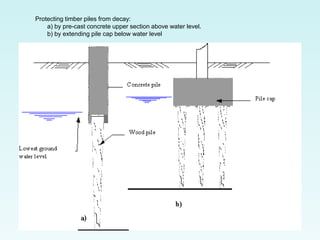

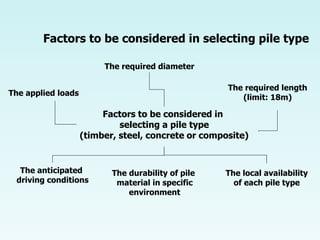

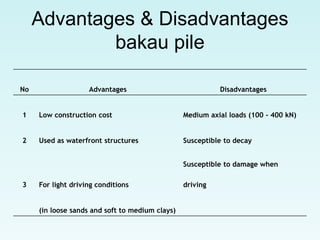

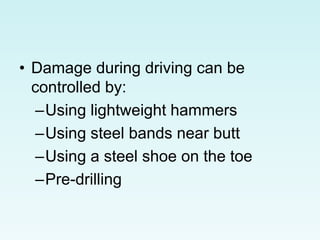

This document provides an overview of building substructures and foundations. It discusses the main types of shallow foundations, which are suitable for smaller buildings, including pad footings, strip footings, and raft foundations. It also discusses deep foundations, which are required for larger buildings or where soil conditions require foundations to be placed deeper, such as pile foundations. The key functions of foundations are to distribute structural loads over a large soil area, transmit loads uniformly, and provide a stable base for the building. Foundation type selection depends on factors like building loads, soil type, and cost.