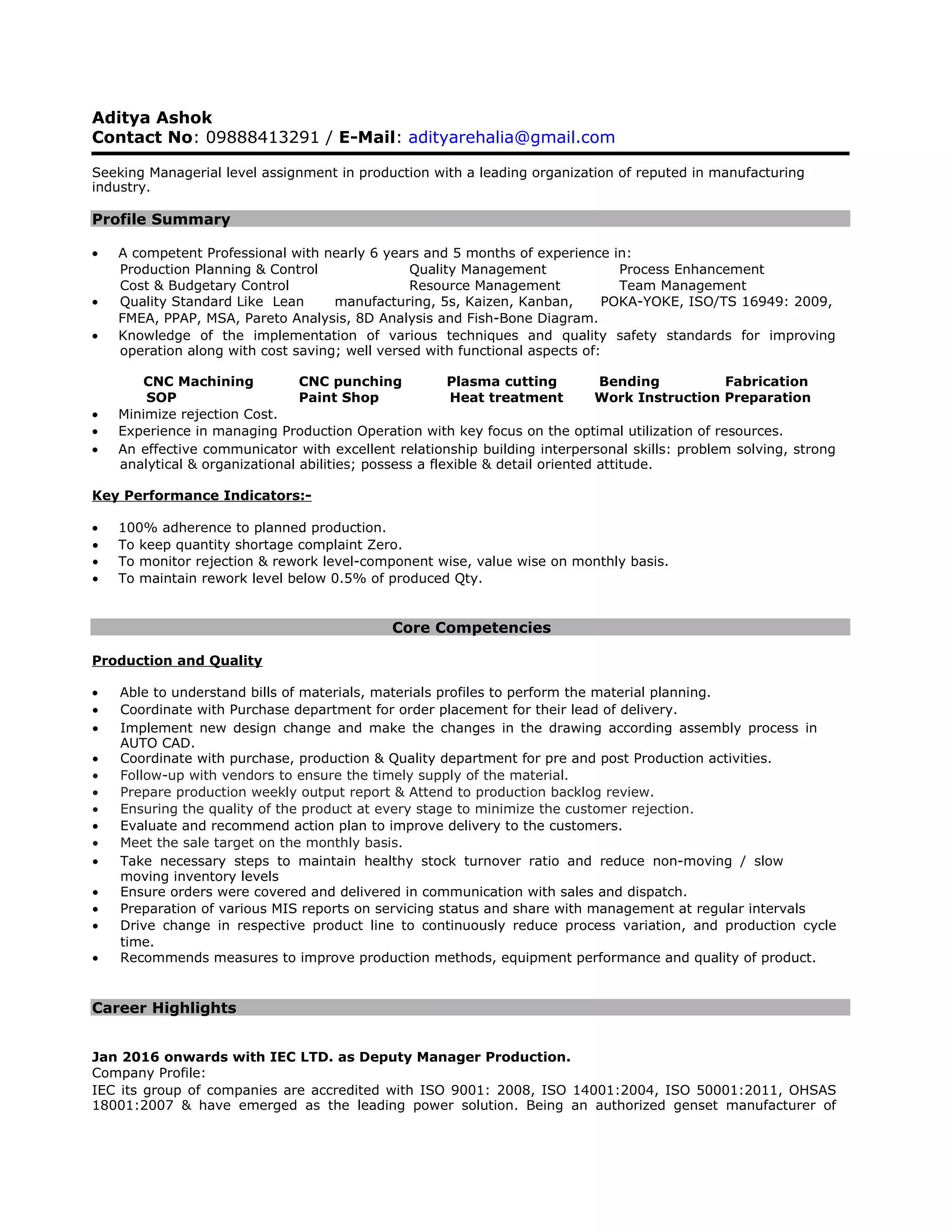

Aditya Ashok is seeking a managerial role in production management with over 6 years of experience in production planning and control, quality management, process enhancement, and cost and budgetary control. He has extensive experience with quality standards and certifications like ISO and Lean manufacturing. He has a proven track record of optimizing resource utilization and minimizing rejection costs. His previous roles include positions as Deputy Manager Production and Production Cum Quality Manager.