Embed presentation

Downloaded 13 times

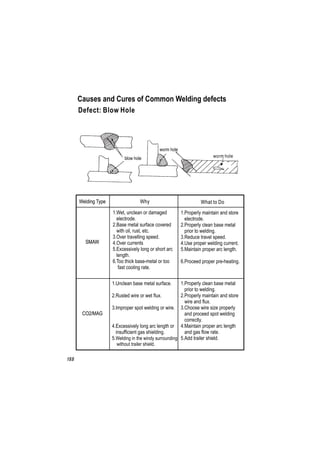

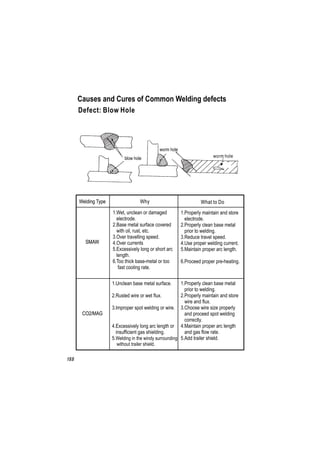

This document discusses common welding defects such as blow holes and worm holes, their causes, and how to prevent them. Blow holes can be caused by an unclean base metal surface, rusty wire or wet flux, improper spot welding or wire size, excessively long arc length or insufficient gas shielding, or welding in windy conditions without a shield. Worm holes are caused by a wet, unclean, or damaged electrode, base metal covered in oil or rust, over traveling speed, over currents, excessively long or short arc length, or a base metal that is too thick or cools too quickly. To prevent these defects, welders should properly clean the base metal, maintain equipment, use proper currents