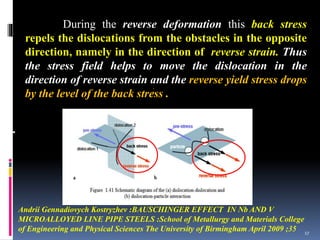

This document summarizes a seminar presentation on the Bauschinger effect given by Dr. Deeksha Bhanotia at NIMS Dental College. It begins with an introduction defining the Bauschinger effect as the phenomenon where the yield stress of a metal is lower in the reverse direction after it has been plastically deformed in one direction. It then discusses the general physical properties of metals, theories of the Bauschinger effect including back stress theory and Orowan theory, parameters used to describe the effect, and applications in orthodontics including space closure mechanics and loop design. The conclusion states that the principal cause of the effect appears to be the creation of mobile dislocations which exhibit directional resistance to motion