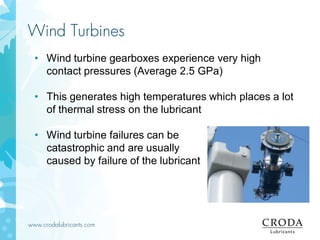

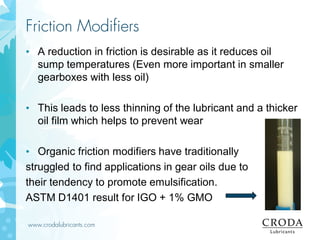

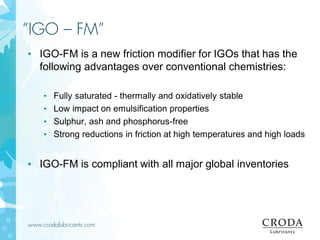

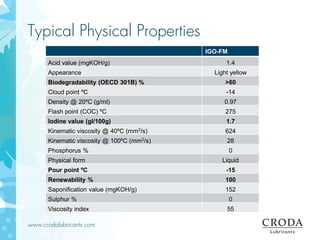

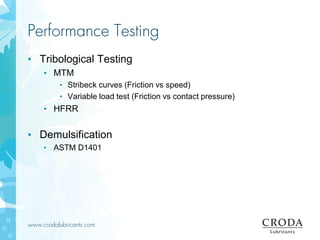

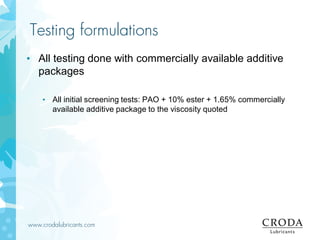

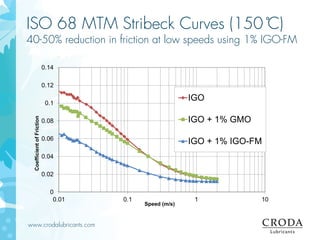

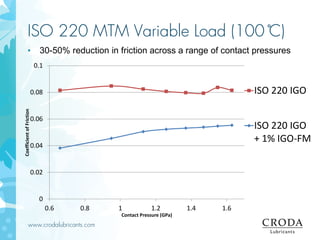

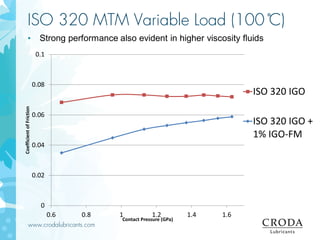

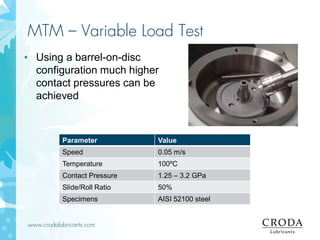

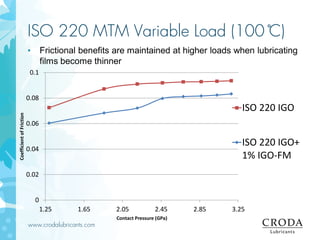

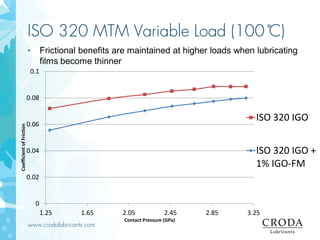

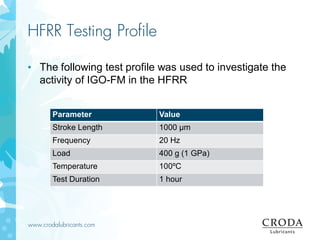

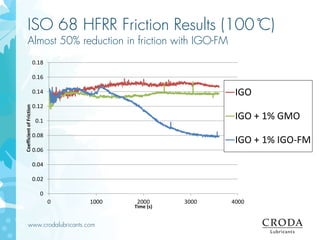

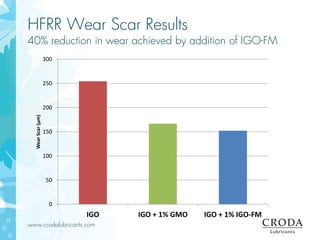

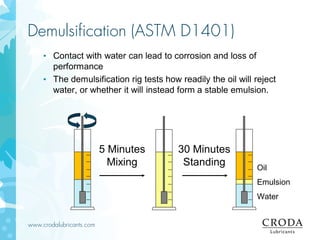

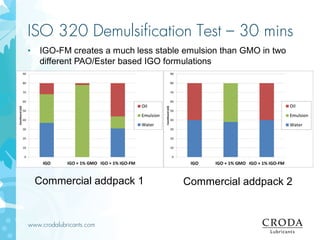

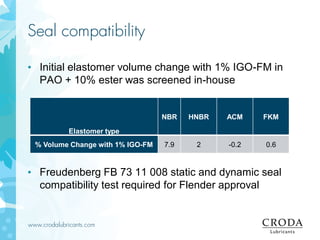

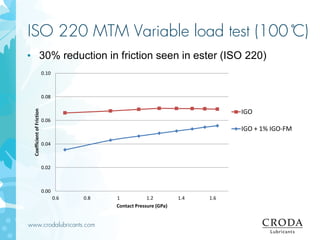

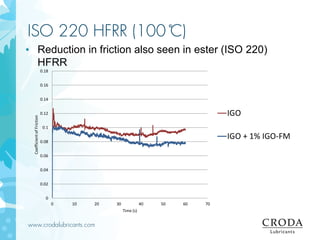

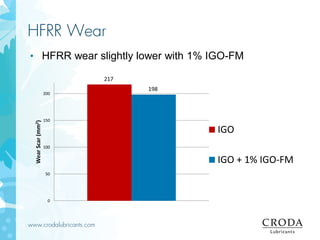

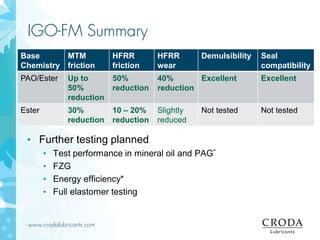

The document discusses the development of a new organic friction modifier, igo-fm, for industrial gear oils (IGOs), emphasizing its benefits in reducing friction, enhancing demulsibility, and maintaining compatibility with seals. Tribological testing shows that igo-fm significantly reduces friction and wear under high temperatures and loads, making it suitable for applications like wind turbines and heavy-duty gear systems. Further testing is planned to evaluate its performance in various base oil technologies and elastomer compatibility.