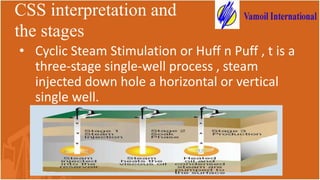

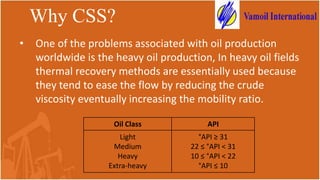

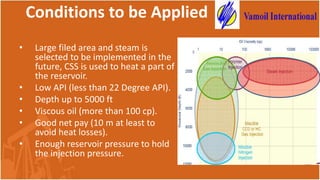

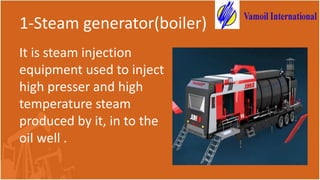

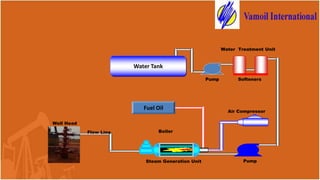

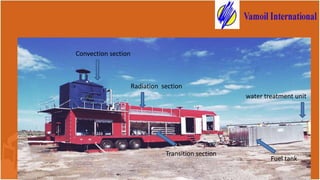

Cyclic Steam Stimulation (CSS) is a thermal recovery method used in heavy oil fields. It is a three-stage single-well process where steam is injected down a well to heat the reservoir and reduce oil viscosity. CSS involves injecting high pressure steam from a steam generator through an insulated pipeline to the wellhead. Key equipment includes the steam generator, water treatment unit, insulated pipeline and downhole testing instruments. The process works by heating the reservoir in cycles to ease oil flow and increase recovery.