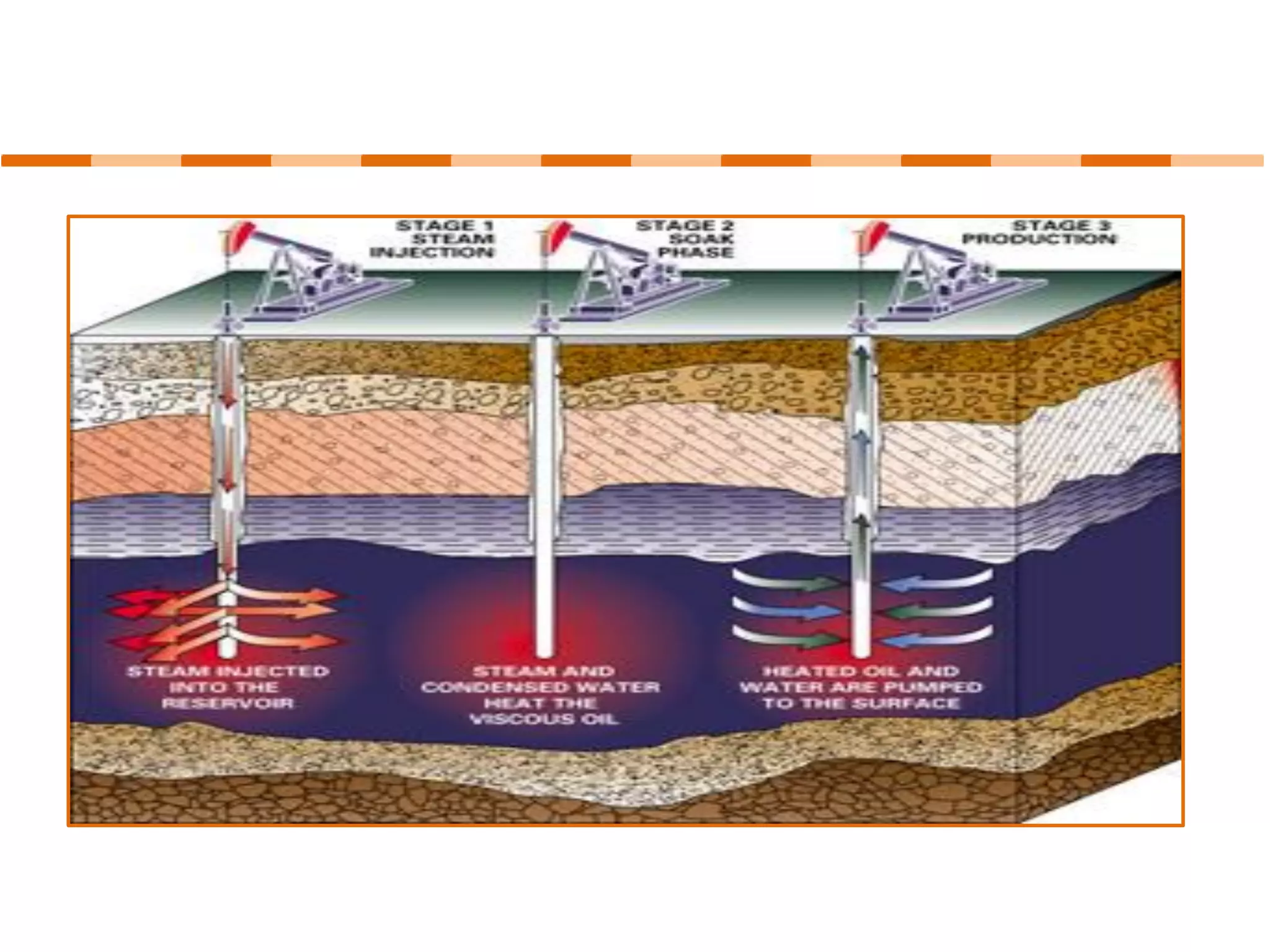

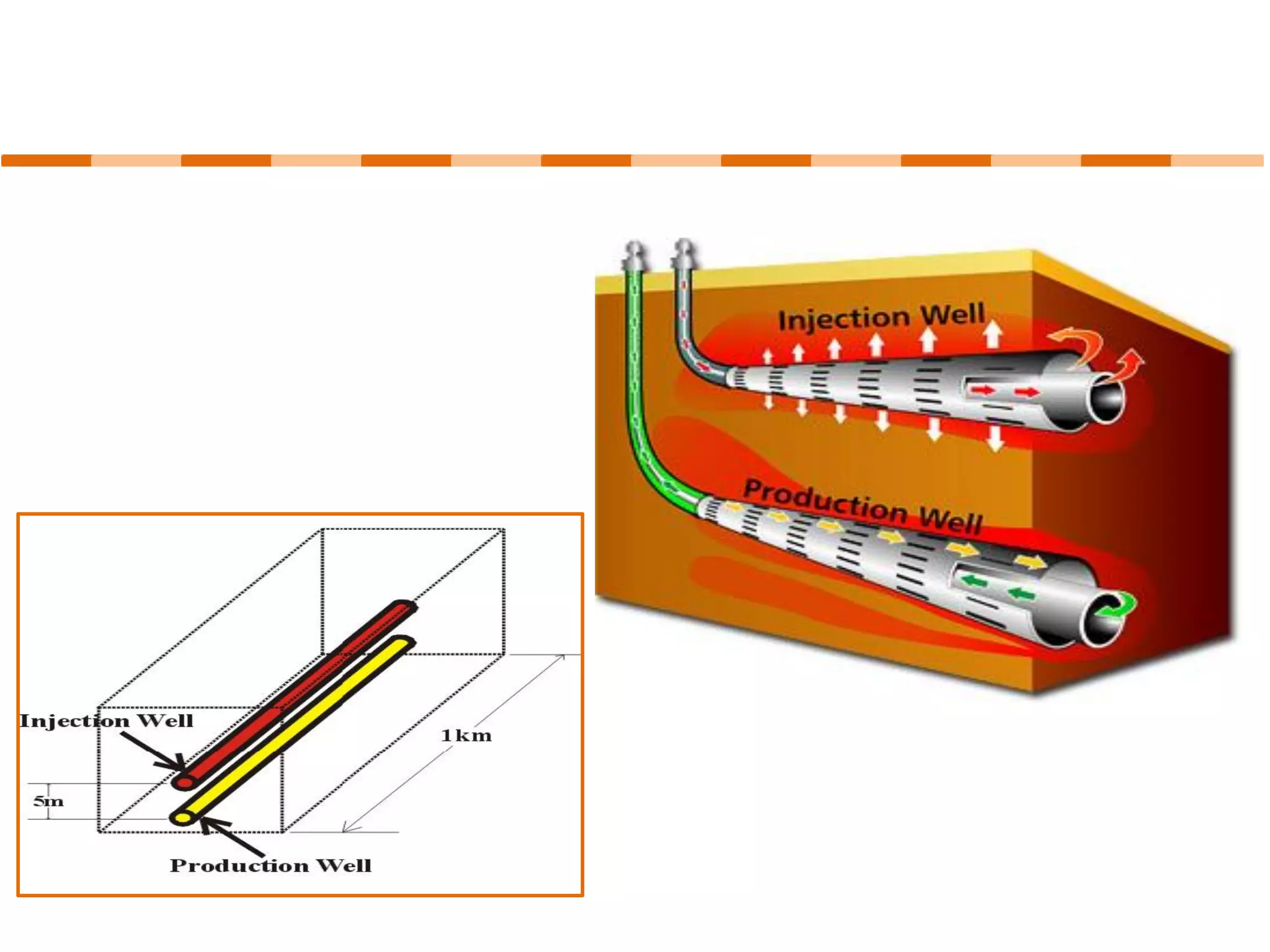

Thermal EOR methods include steam injection, cyclic steam stimulation, insitu combustion, and steam assisted gravity drainage. Thermal methods supply heat to the reservoir to reduce oil viscosity and allow for improved recovery. Each method has different injection and production mechanisms, suitable reservoir properties, and advantages and disadvantages. SAGD uses horizontal wells to inject steam and produce heated oil, allowing for high recovery of extra heavy oil.