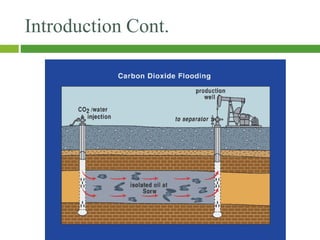

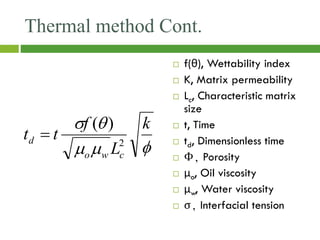

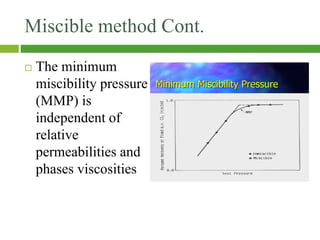

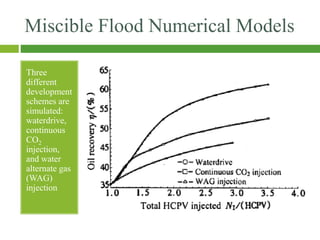

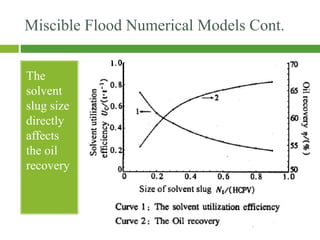

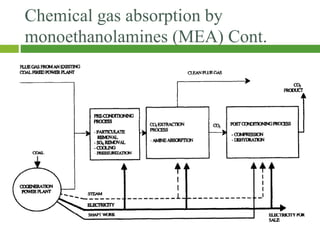

The document discusses enhanced oil recovery (EOR) methods utilizing CO2, highlighting thermal, chemical, and miscible techniques to improve oil extraction from reservoirs. It details processes like steam-CO2 injection and the use of monoethanolamines for CO2 absorption, noting the economic and environmental challenges of CO2 capture for EOR. Conclusively, optimizing CO2 extraction from coal-fired plants is presented as both feasible and beneficial.