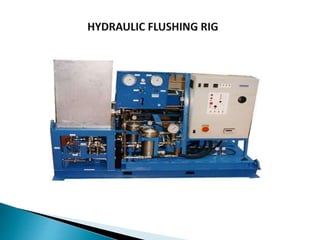

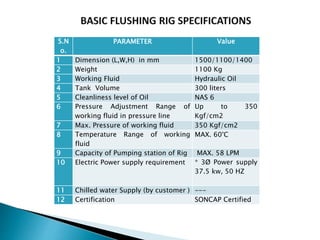

This document describes the specifications of a hydraulic flushing rig. It can be used to clean systems contaminated with large amounts of debris. The rig contains:

- A 300 liter stainless steel tank for hydraulic oil

- Pumps capable of 58 LPM at 350 kg/cm2 pressure

- Filters down to 2 microns to clean the oil

- A heat exchanger to control oil temperature below 60°C

- All piping and fittings are stainless steel for use with water or oil-based fluids

- Gauges and controls mounted on a stainless steel panel

- It can clean systems to a NAS 6 cleanliness standard and is certified.