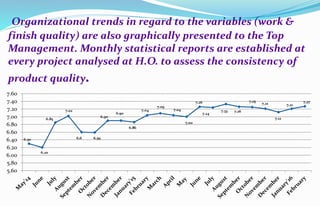

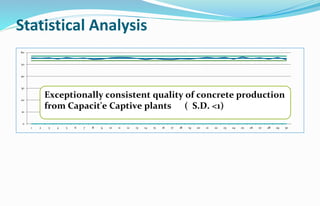

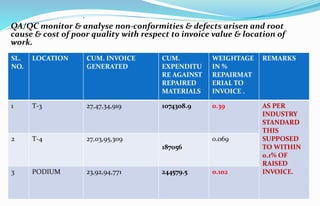

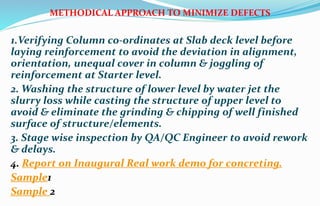

The document summarizes the quality assurance and quality control (QA/QC) processes at Capacit'e Infraprojects Ltd. It describes the organizational structure of the QA/QC department, which reports directly to top management. It outlines several key features of Capacit'e's quality management system including standardized processes, inspection plans, rigorous material testing, and statistical analysis of quality trends. It also highlights some technical achievements and best practices implemented to minimize defects and ensure consistent high quality in construction projects.