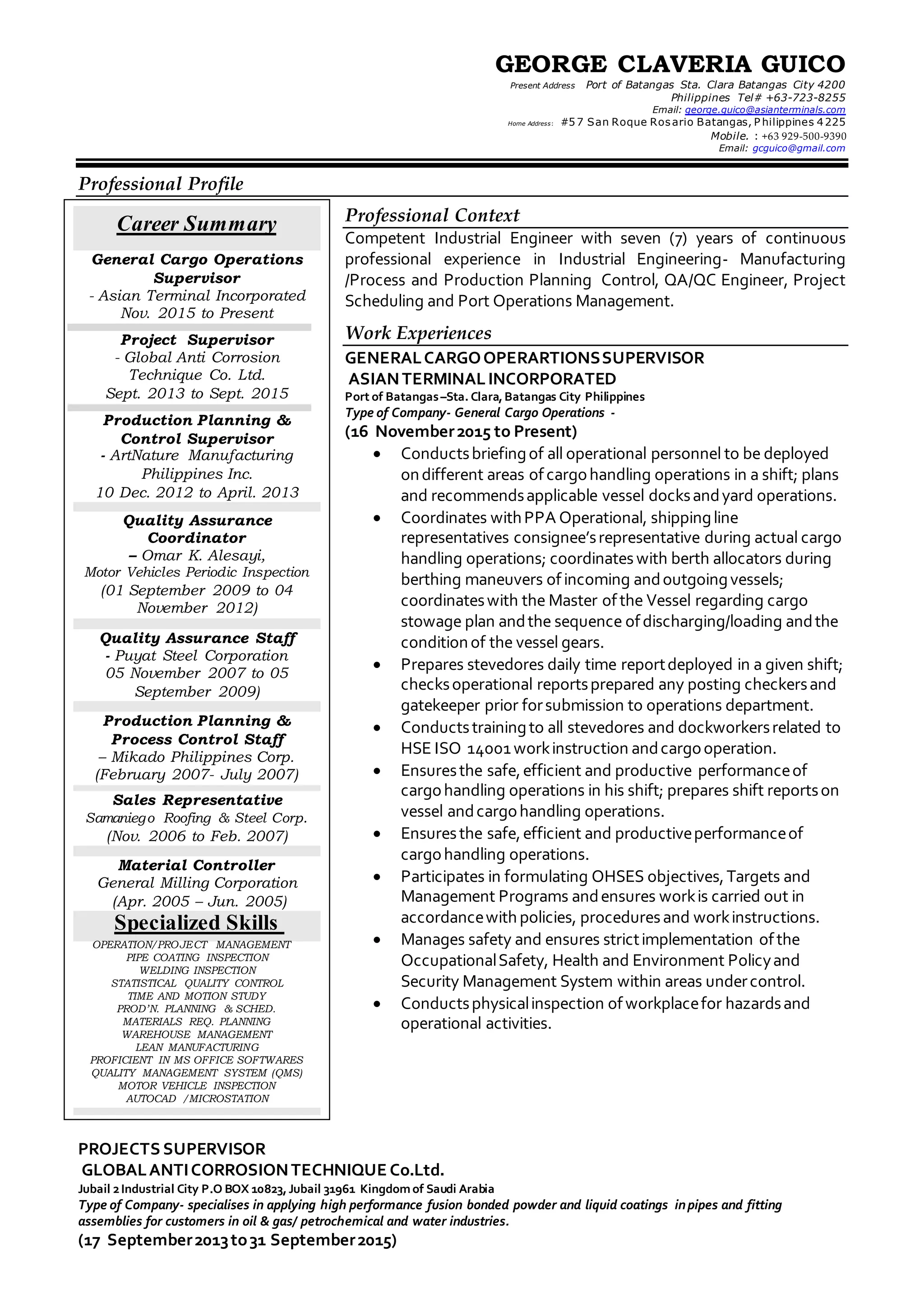

This document provides a summary of George Claveria Guico's professional experience and qualifications. It includes his current role as General Cargo Operations Supervisor for Asian Terminal Incorporated in Batangas City, Philippines, which he has held since November 2015. Prior to this, he was a Project Supervisor for Global Anti Corrosion Technique Co. Ltd. in Jubail, Saudi Arabia from September 2013 to September 2015. He has over 7 years of experience in roles such as Production Planning & Control Supervisor, Quality Assurance Coordinator, Quality Assurance Staff, Production Planning & Process Control Staff, and Material Controller. The document lists his responsibilities and duties in each role.