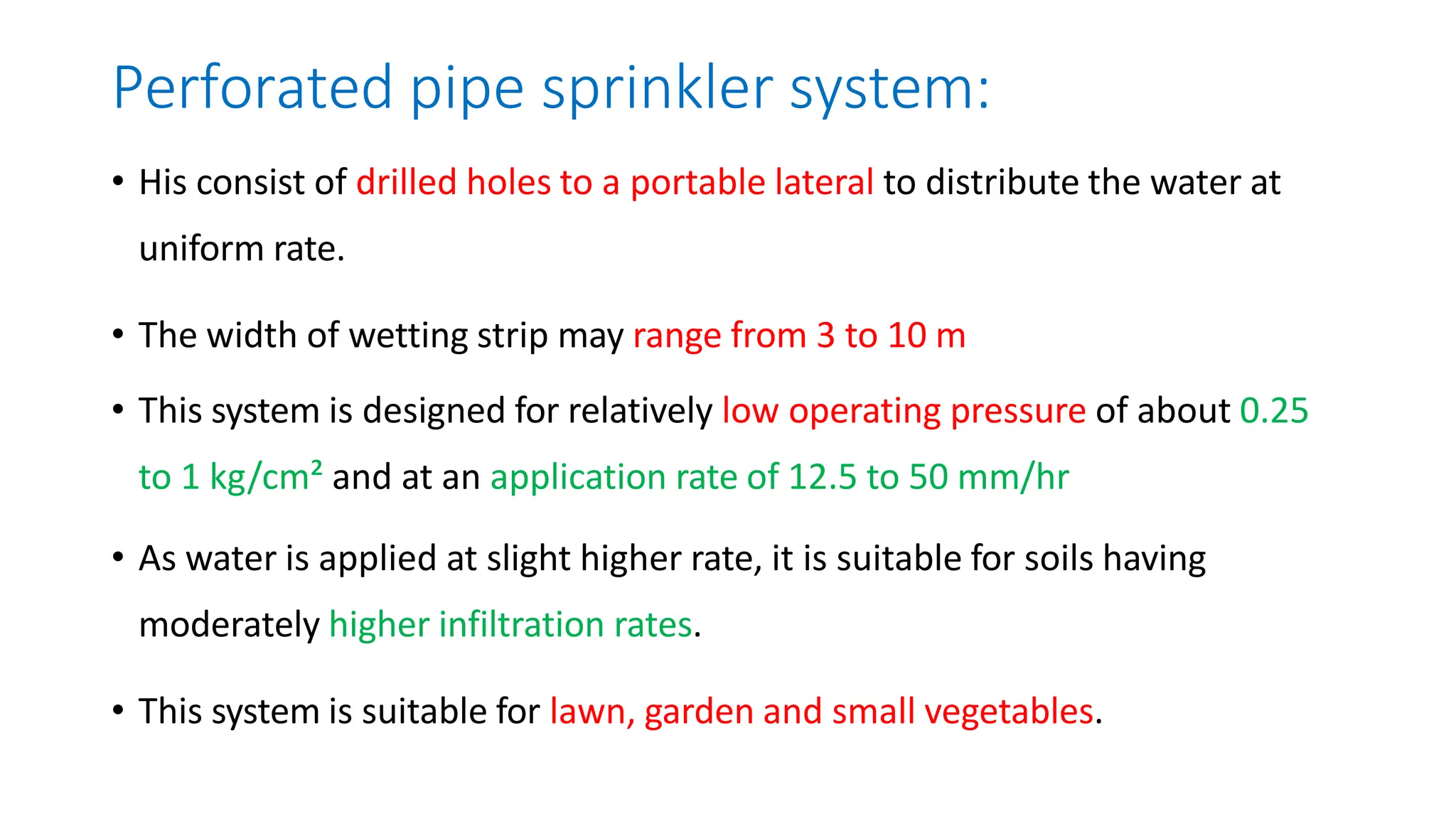

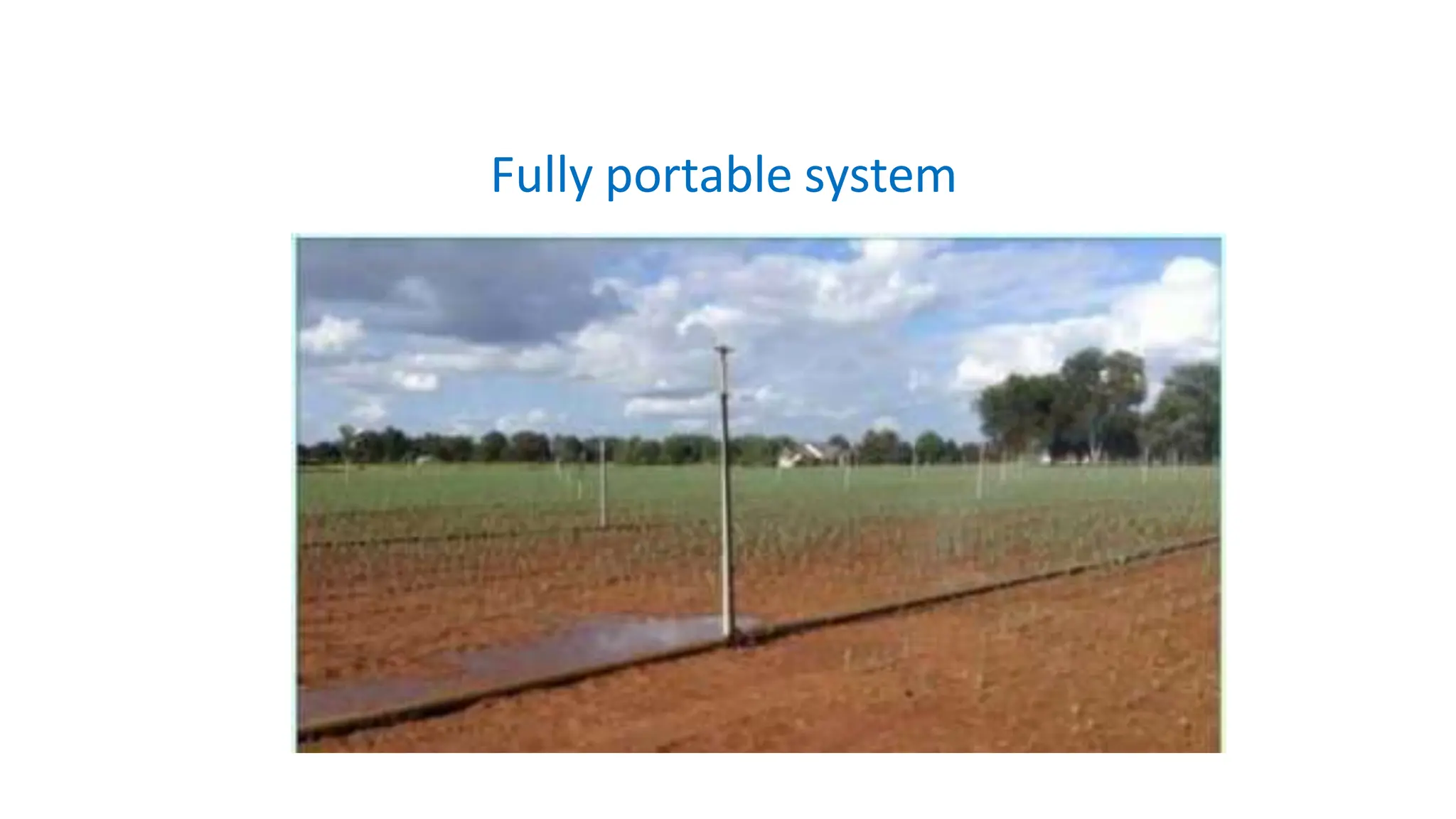

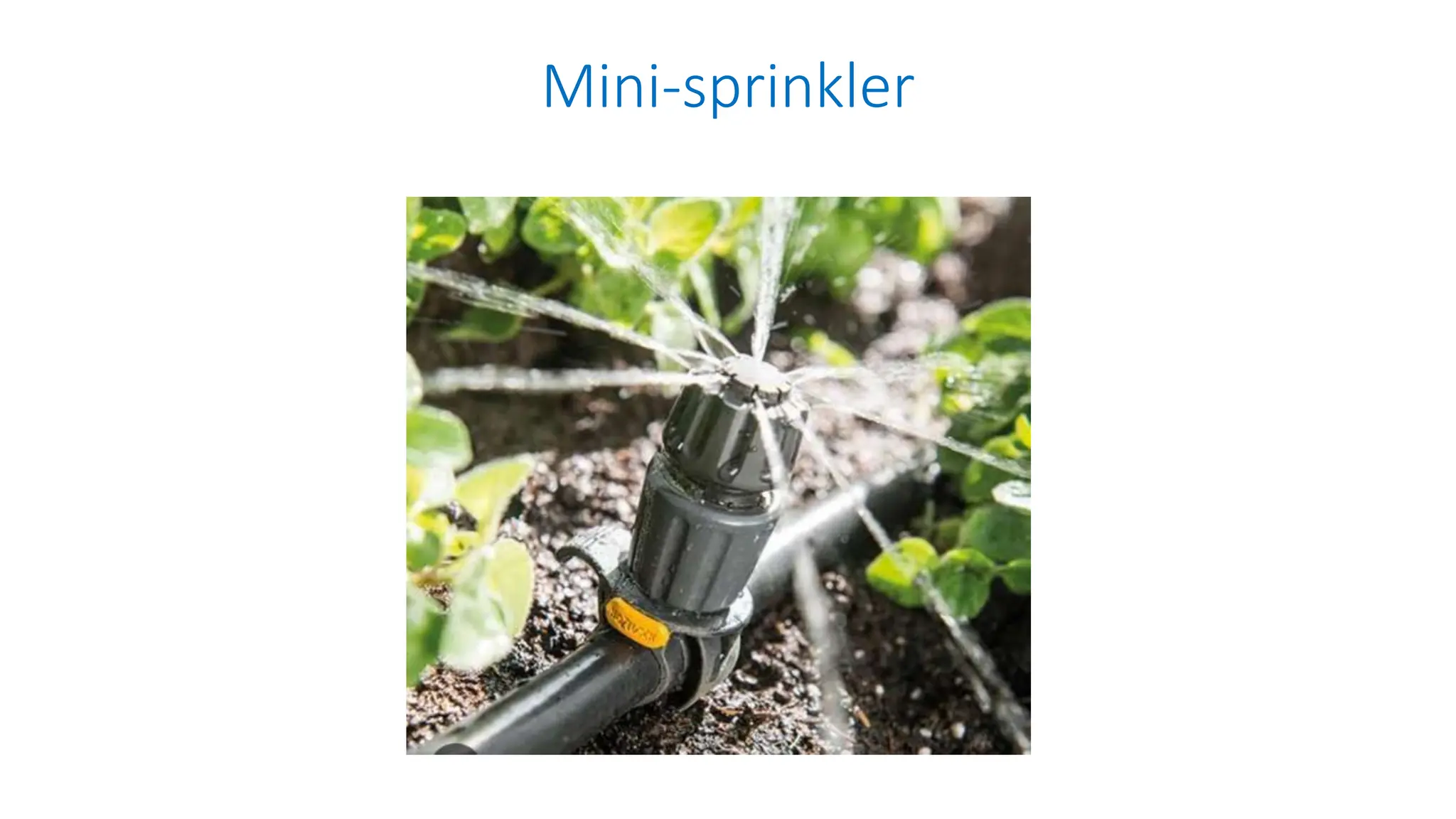

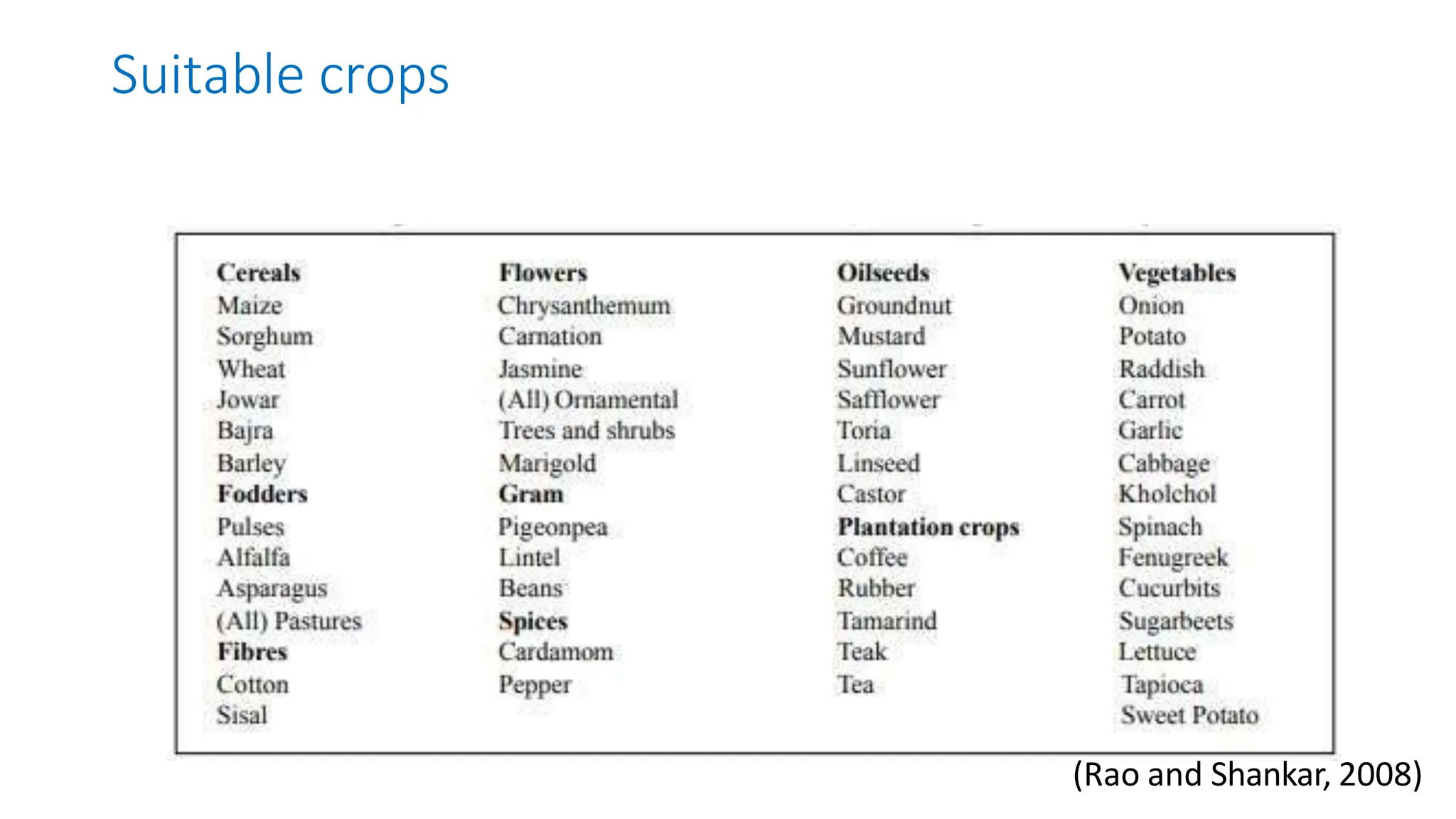

Sprinkler irrigation involves spraying water over crops through a network of pipes and nozzles under pressure. It saves water compared to surface irrigation by applying water directly to the root zone in a manner similar to rainfall. The document discusses various types of sprinkler systems classified based on method of application, portability, precipitation rate, movement, and operation principle. It also covers advantages like water conservation, components, suitable crops and soils, design, maintenance, and troubleshooting of sprinkler irrigation systems. However, its use in India is still low due to high costs and lack of awareness among farmers.