The document summarizes sprinkler irrigation systems. Key points include:

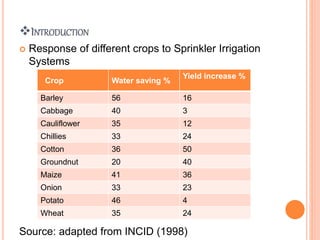

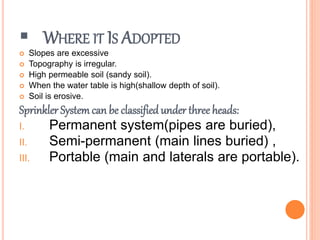

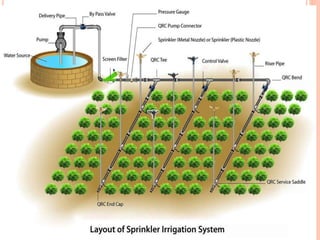

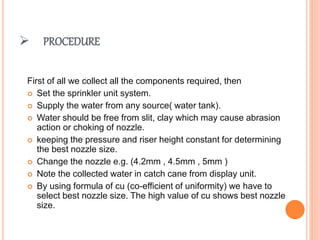

Sprinkler systems distribute water through pipes and spray nozzles, mimicking rain, and allow for more efficient water usage than surface irrigation. They are well-suited for sloping land, sandy soils, and where water tables are high. Permanent systems have buried pipes while portable systems are movable. Advantages include water control, yield increases, and less labor needed. Components include a water source, pump, pipes, risers, nozzles, and filters. Implementation costs are higher than gravity systems however.