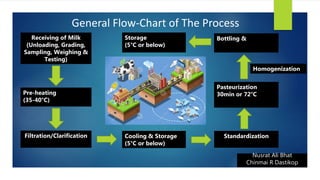

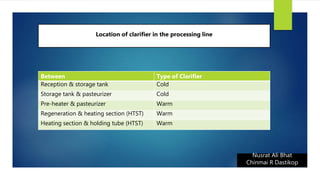

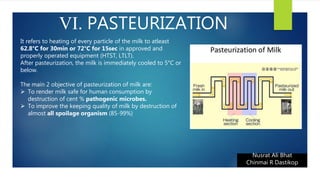

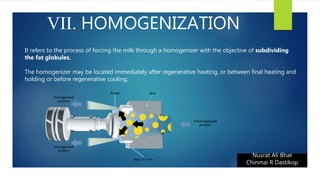

The document provides an overview of operations in a milk processing plant, emphasizing the perishable nature of milk and the importance of preserving it to prevent spoilage and food-borne illnesses. It details the various stages of milk processing, including receiving, pre-heating, filtration, cooling, standardization, pasteurization, homogenization, and bottling, with specific methods and equipment used. Modern advancements in milk processing technology enhance product quality, reduce labor, increase efficiency, and maintain sanitation standards.