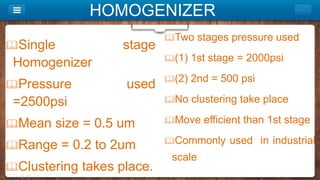

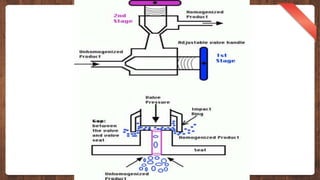

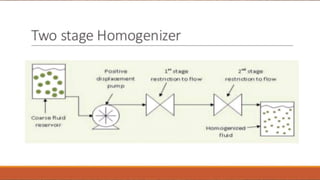

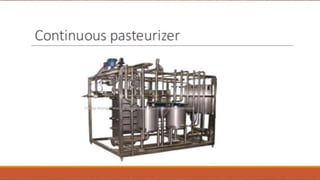

The document discusses the Indian milk industry. It notes that India is one of the largest milk producers in the world, contributing about 15% of global production. The Indian milk industry is valued at around $70 billion. Milk is collected from over 10 million dairy farmers and sold through dairy cooperatives. Key equipment used includes separators to separate cream from milk, homogenizers to reduce fat globule size, storage tanks, and pasteurizers. Common pasteurization methods are batch, continuous, and flash (HTST). Packaging is an important final step, with machines that fill pouches or reusable containers like bottles.