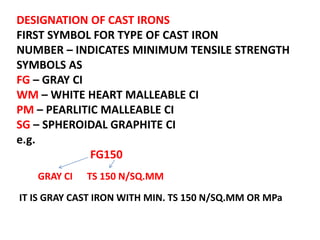

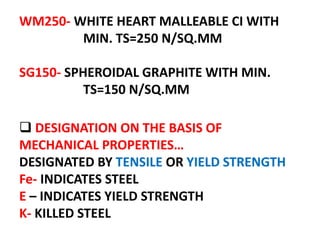

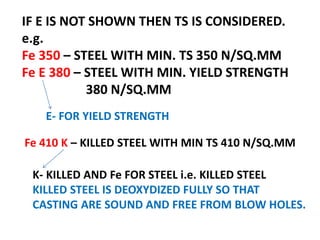

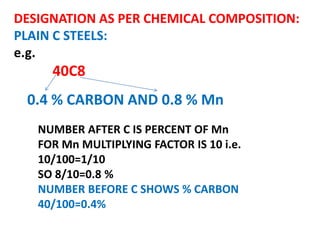

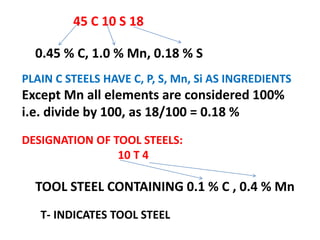

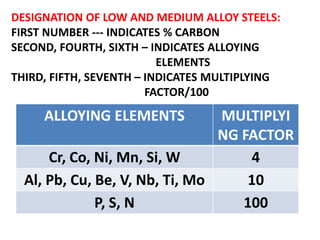

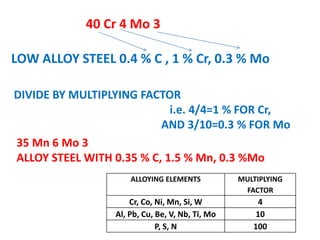

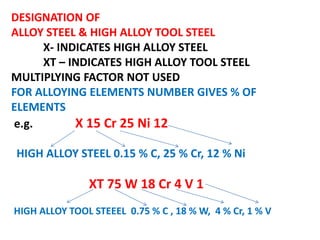

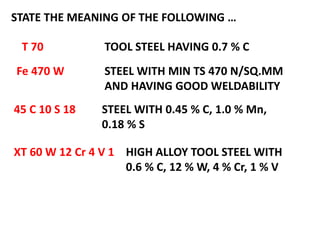

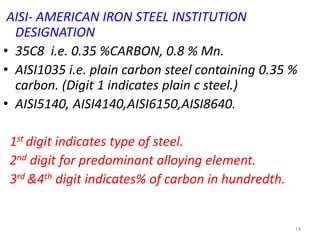

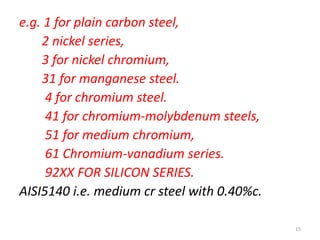

The document discusses material specification and designation systems. It describes how materials are classified and designated according to standards like BIS, AISI, and SAE. It then summarizes the designation systems for various material types like cast irons, plain carbon steels, tool steels, low-alloy steels, and high-alloy steels. The designation systems are based on mechanical properties, chemical composition, or both. Key details like material type, percentage of elements, and minimum properties are encoded in the designation codes.