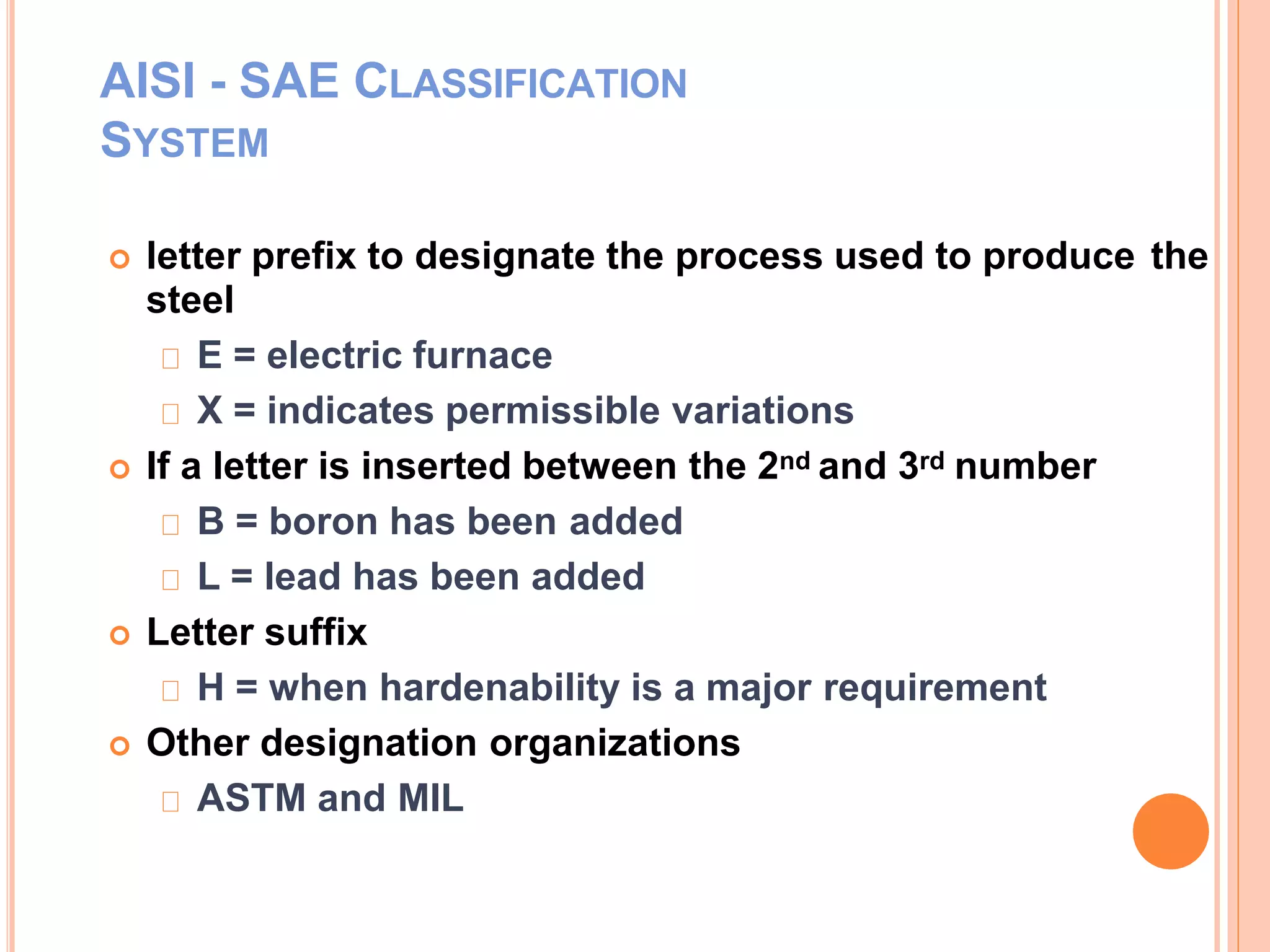

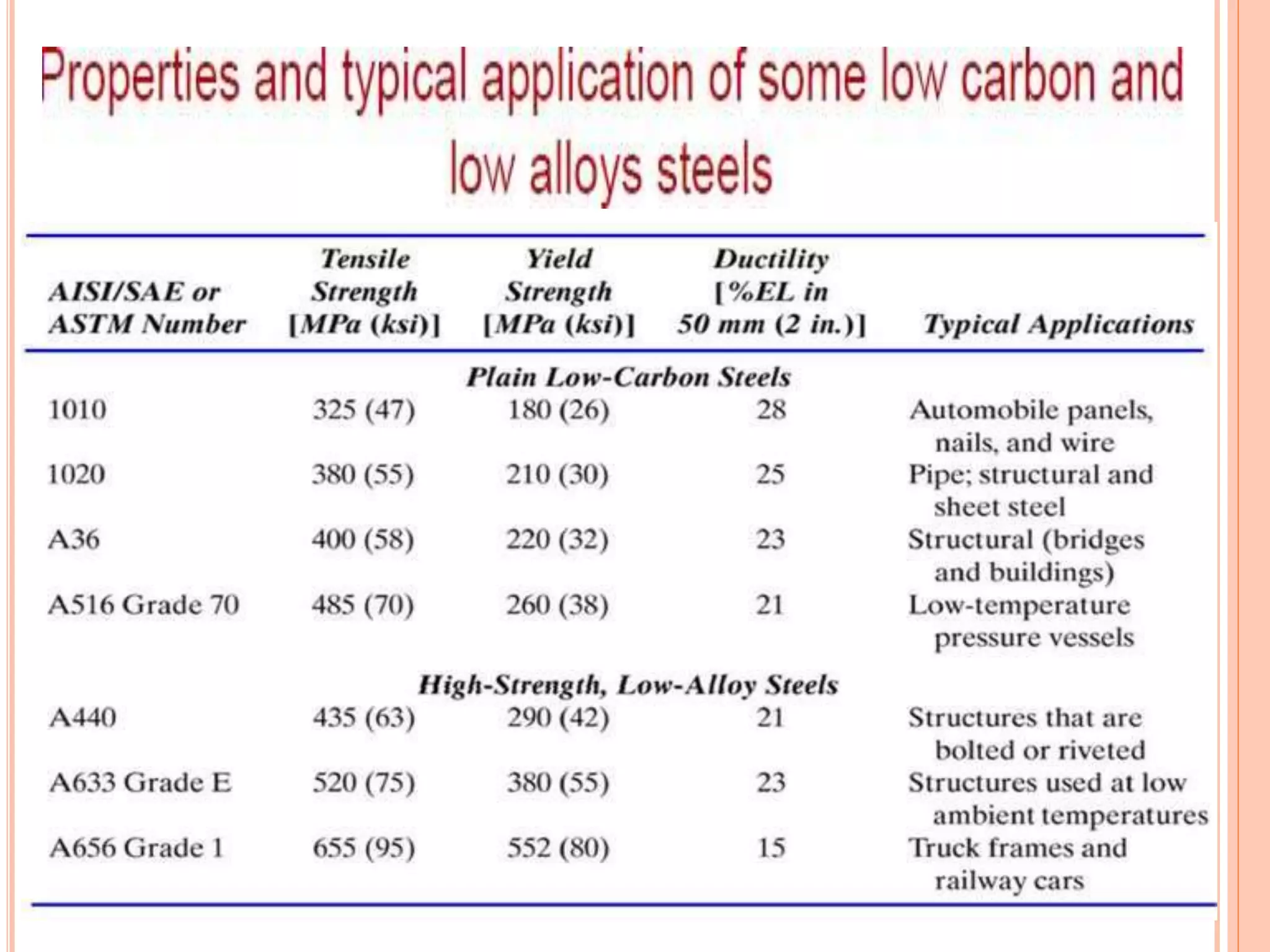

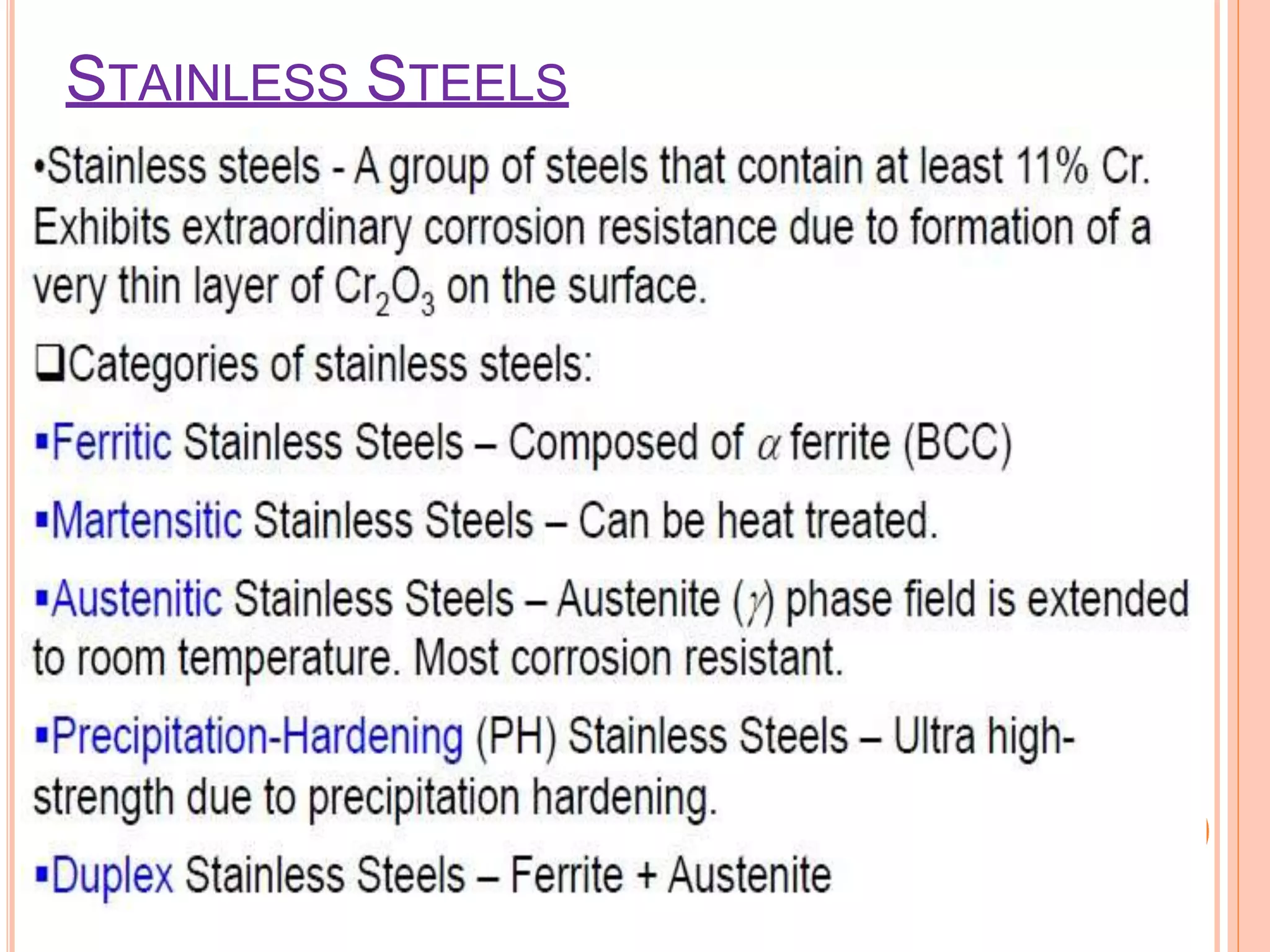

This document discusses the classification of steels based on their carbon content and alloying elements. It describes low carbon steels as containing less than 0.25% carbon, being tough, malleable, and ductile. Medium carbon steels range from 0.25 to 0.6% carbon and can be heat treated to increase strength. High carbon steels contain more than 0.6% carbon. Alloying elements like manganese, chromium, nickel, and molybdenum are discussed and their effects on properties such as strength, hardness, toughness, and corrosion resistance. Common applications of different steel types are also mentioned.