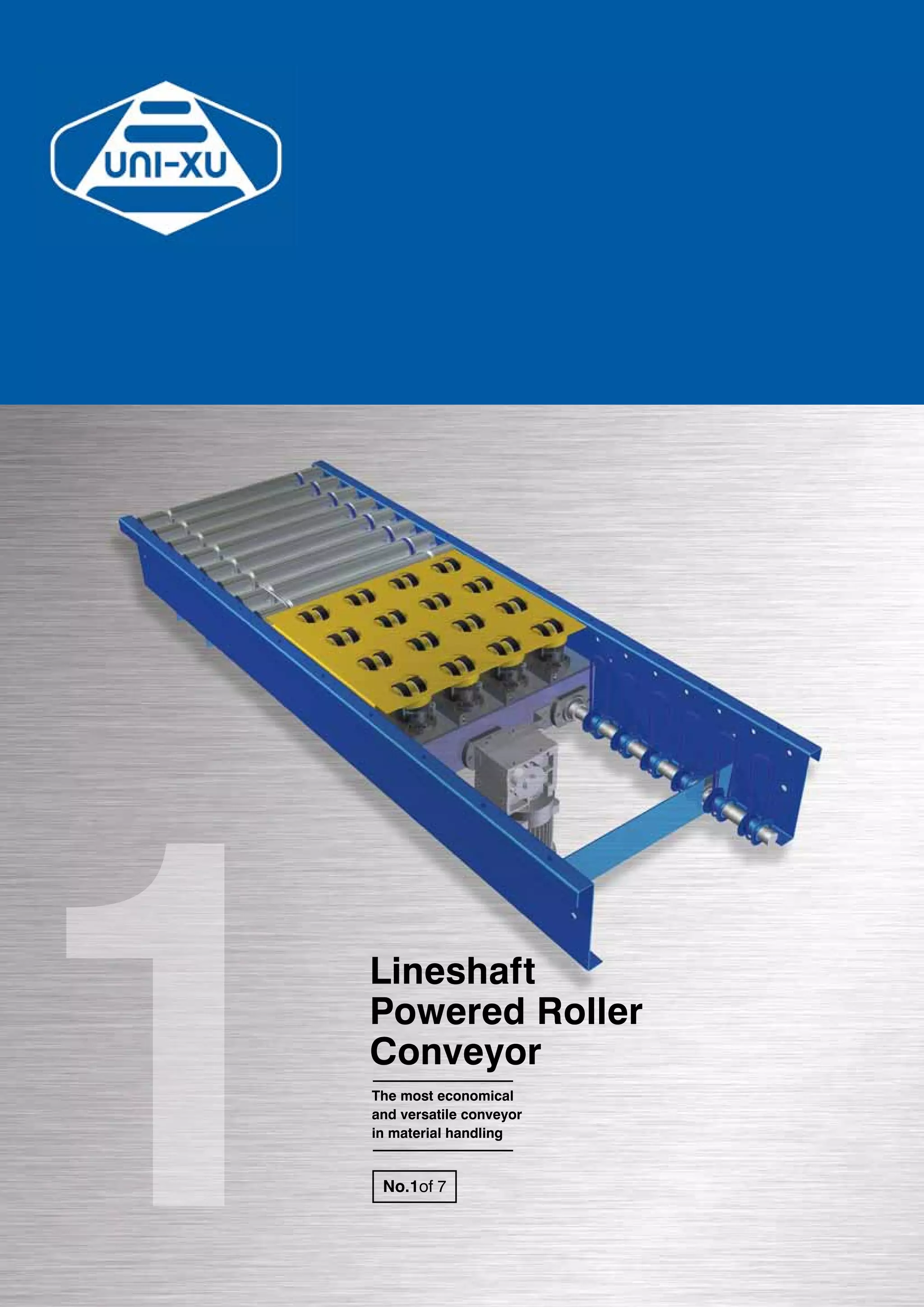

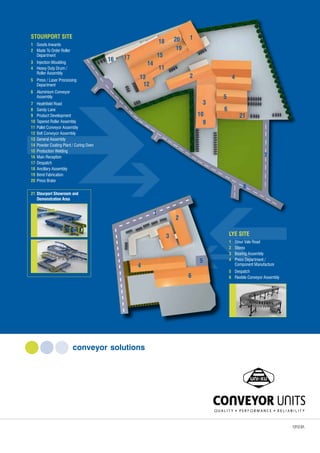

This document provides an overview and specifications for various types of conveyor systems manufactured by uni-xu®. It describes the Lineshaft Powered Roller Conveyor as the most versatile and economical conveyor available. The document includes an index listing 27 different conveyor components and accessories, with brief descriptions and specifications for each. It emphasizes the modularity, flexibility, and adaptability of the uni-xu® conveyor systems for material handling applications.