1) The document presents a study applying Tabu Search to schedule jobs in a textile manufacturing system in order to minimize maximum lateness on a single machine.

2) An example problem is described with 20 jobs, including processing times and due dates. An initial schedule is generated using the Earliest Due Date dispatching rule.

3) Tabu Search is then applied for 20 iterations to improve the schedule. The results show that Tabu Search is an effective heuristic for job scheduling problems like this one.

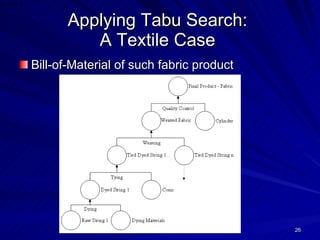

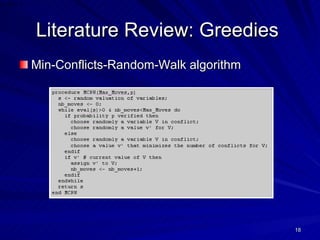

![Literature Review: Greedies Moreover, like it is aimed in this paper, tabu search is used in scheduling jobs in textile manufacturing systems and proved to be efficient. In their paper, Tucci and Rinaldi [31] describes a typical fabric production system and applies tabu search.](https://image.slidesharecdn.com/snmtauctv-1223539873035019-8/85/Snm-Tauctv-23-320.jpg)