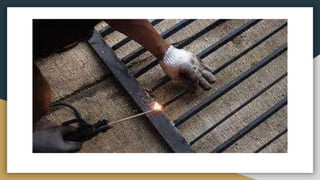

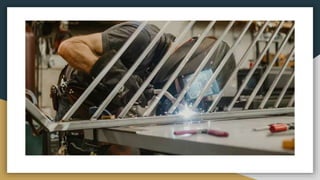

The document provides an overview of welding stringer beads including definitions of key terms, objectives of the lesson, and a discussion of techniques. It outlines activities for student groups on preparing materials, setting up equipment, and demonstrating procedures. Questions are provided to evaluate understanding of the importance of proper preparations and techniques for welding stringer beads, specifically maintaining consistent speed, angle and arc length to produce an even weld. Students are assigned to research fire extinguishers.