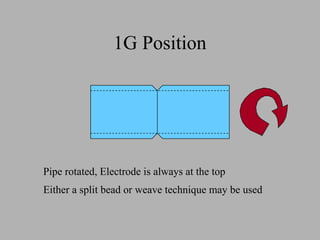

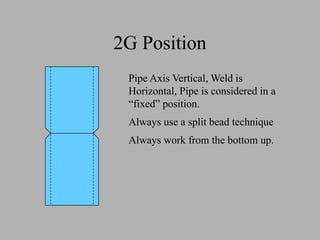

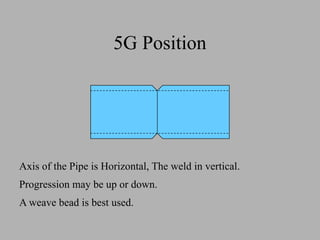

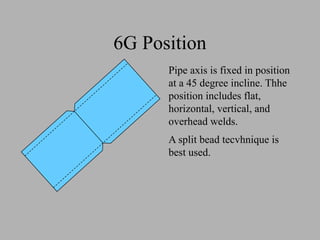

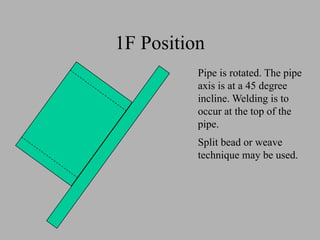

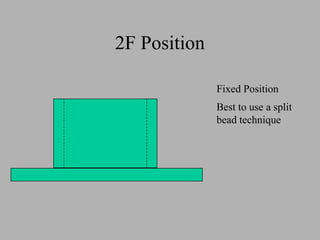

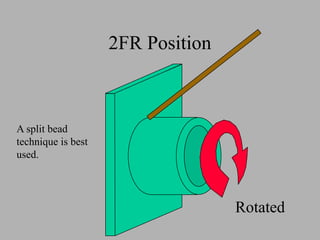

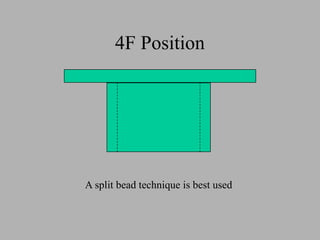

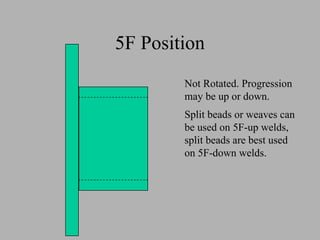

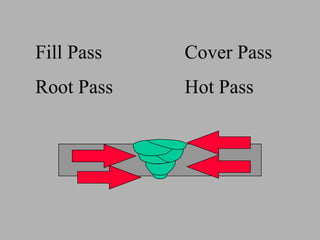

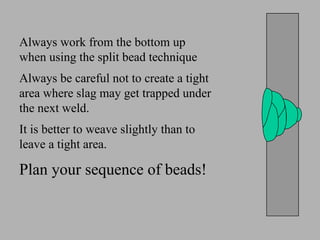

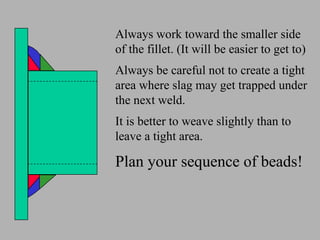

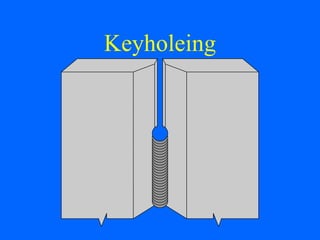

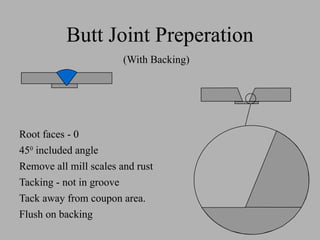

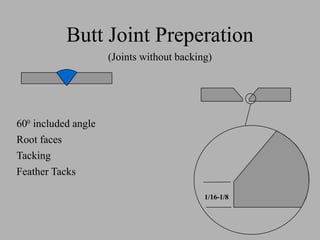

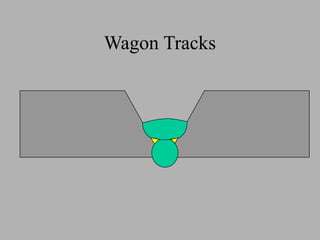

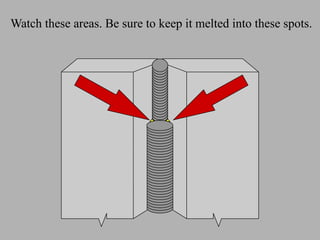

The document details various SMAW pipe welding techniques and positions, including 1G, 2G, 5G, and 6G, each with specific recommendations for welding methods and bead sequences. Key points include the importance of avoiding tight areas for slag, using effective interpass grinding, and varying electrode angles and arc lengths to control heat and penetration. Additional tips cover tacking methods, joint preparation, and maintaining proper puddle observation and travel speed.