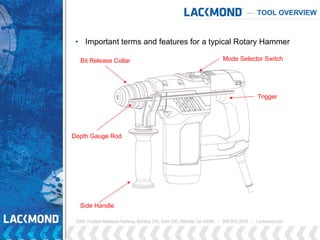

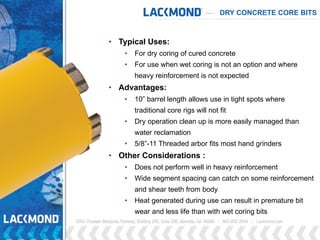

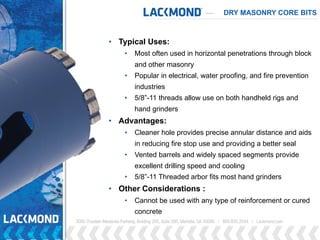

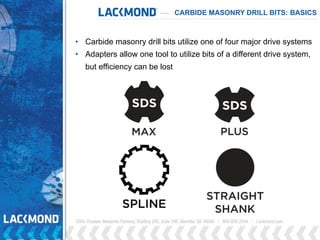

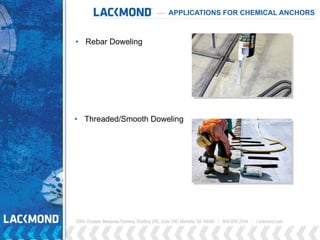

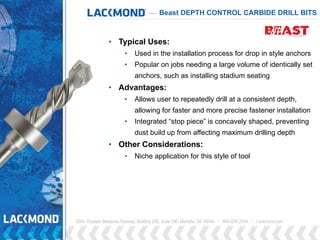

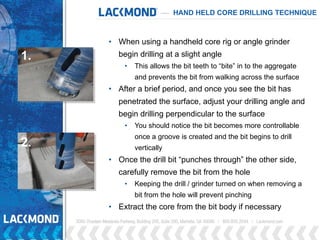

This document provides an overview and training on coring and drilling. It discusses safety procedures and required protective equipment. It then reviews various coring and drilling tools, including their features and uses. The document focuses on diamond core bits, explaining different types for various applications. It also covers carbide drill bits, their drive systems, and applications for installing mechanical and chemical anchors. Hands-on training is recommended to reinforce concepts from the classroom instruction.