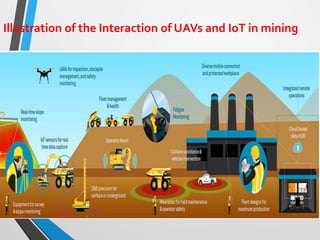

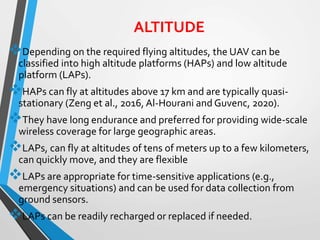

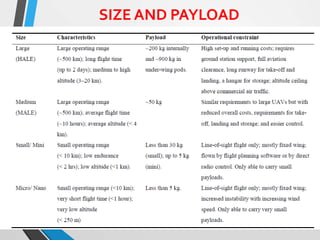

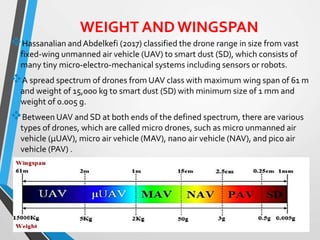

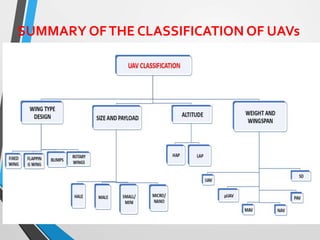

The document discusses how unmanned aerial vehicles (UAVs) and internet of things (IoT) technologies can enable smart mining operations. It outlines various applications of drones in surface mining like geotechnical monitoring and safety management. The document also classifies UAVs based on factors such as wing design, altitude, size and payload. While the use of UAVs and IoT presents advantages such as improved efficiency, safety challenges need to be addressed for their widespread adoption in mining.