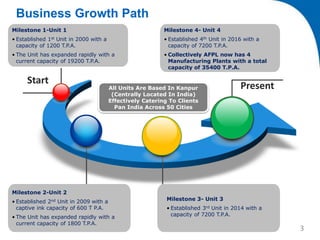

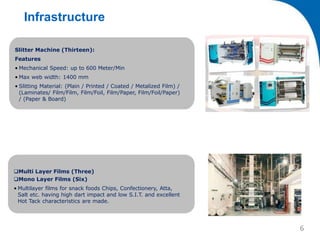

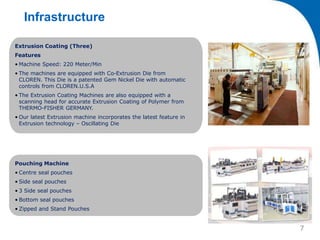

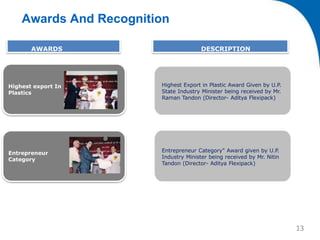

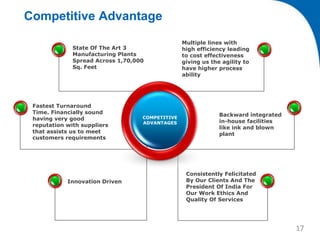

This document provides an overview of Aditya Flexipack Ltd., an Indian flexible packaging company. It summarizes the company's growth path from establishing its first unit in 2000 to now operating four manufacturing plants with a total annual production capacity of 35,400 tonnes per year. The company's vision, mission, and core values focus on customer satisfaction, sustainability, and innovation. The document also outlines the company's manufacturing infrastructure, quality certifications, sustainability efforts, awards received, client list of major brands, and competitive advantages in the flexible packaging industry.