This document provides an introduction to Six Sigma, including:

- The founder of Six Sigma was Bill Smith at Motorola, who developed the approach to reduce process variation.

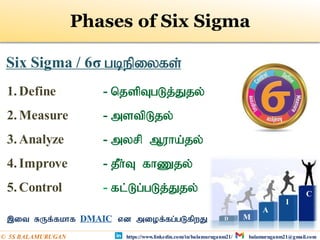

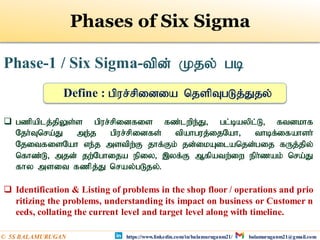

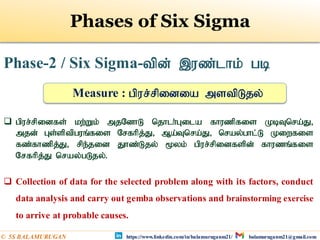

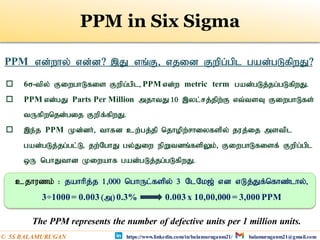

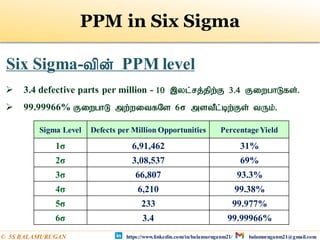

- Six Sigma aims for 3.4 defective parts per million opportunities through its DMAIC methodology.

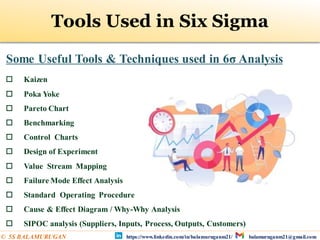

- Tools used in Six Sigma include control charts, design of experiments, and failure mode effect analysis.

- Benefits include reduced costs, increased productivity, and improved customer satisfaction.

- Certification levels include belts such as Yellow, Green, and Black based on expertise and experience.

- Even organizations like the Dabbawala lunch delivery system in Mumbai effectively use Six Sigma principles.

![Benefits of Six Sigma

Nt];l;fis Fiwf;fpwJ.

tUthia mjpfhpf;fpwJ.

Productivity-I mjpfhpf;fpwJ.

nrytpdq;fis Fiwf;fpwJ..

Process variation-I fl;Lg;gLj;JfpwJ.

Customer satisfaction-I cWjp nra;fpwJ.

kdpj kw;Wk; ,ae;jpuj;jpwid Nkk;gLj;JfpwJ

NVA - kjpg;G juhj nray;ghLfisf; Fiwf;fpwJ

Defects free products cw;gj;jpia cWjp nra;fpwJ

Data based decision vLg;gjw;F cWJizahf cs;sJ

jtW kw;Wk; jtW eilngWtjw;fhd tha;g;Gfisf; Fiwf;fpwJ

jhkjq;fis Fiwj;J Procees-d; Ntfj;ij/nray;jpwid Nkk;gLj;JfpwJ.

Six Sigma-tpd; gad;fs;

https://www.linkedin.com/in/balamuruganm21/ balamuruganm21@gmail.com

© 5S BALAMURUGAN](https://image.slidesharecdn.com/sixsigmabasics-tamil-221010093948-5fcac842/85/Six-Sigma-Basics-Tamil-14-320.jpg)