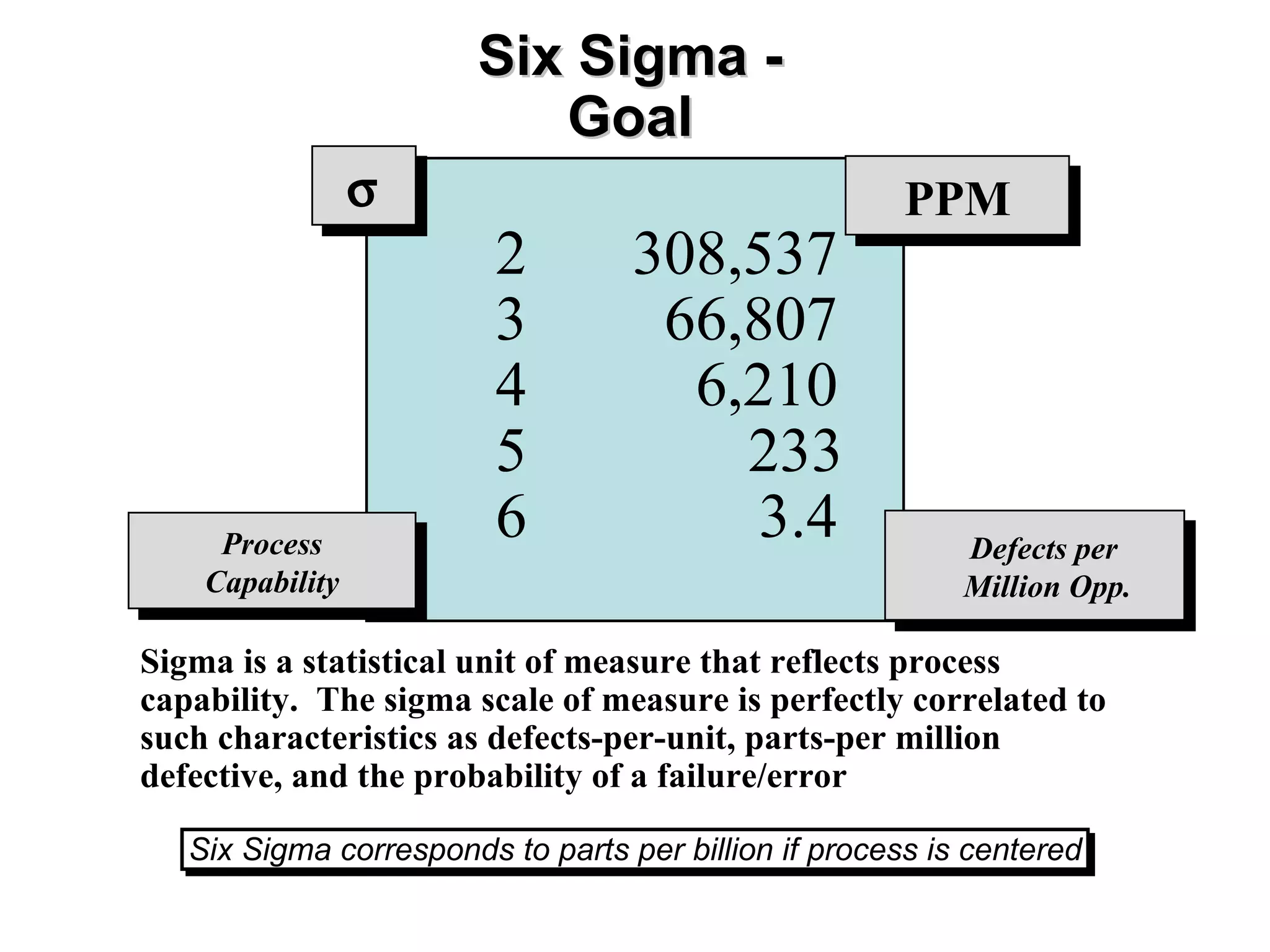

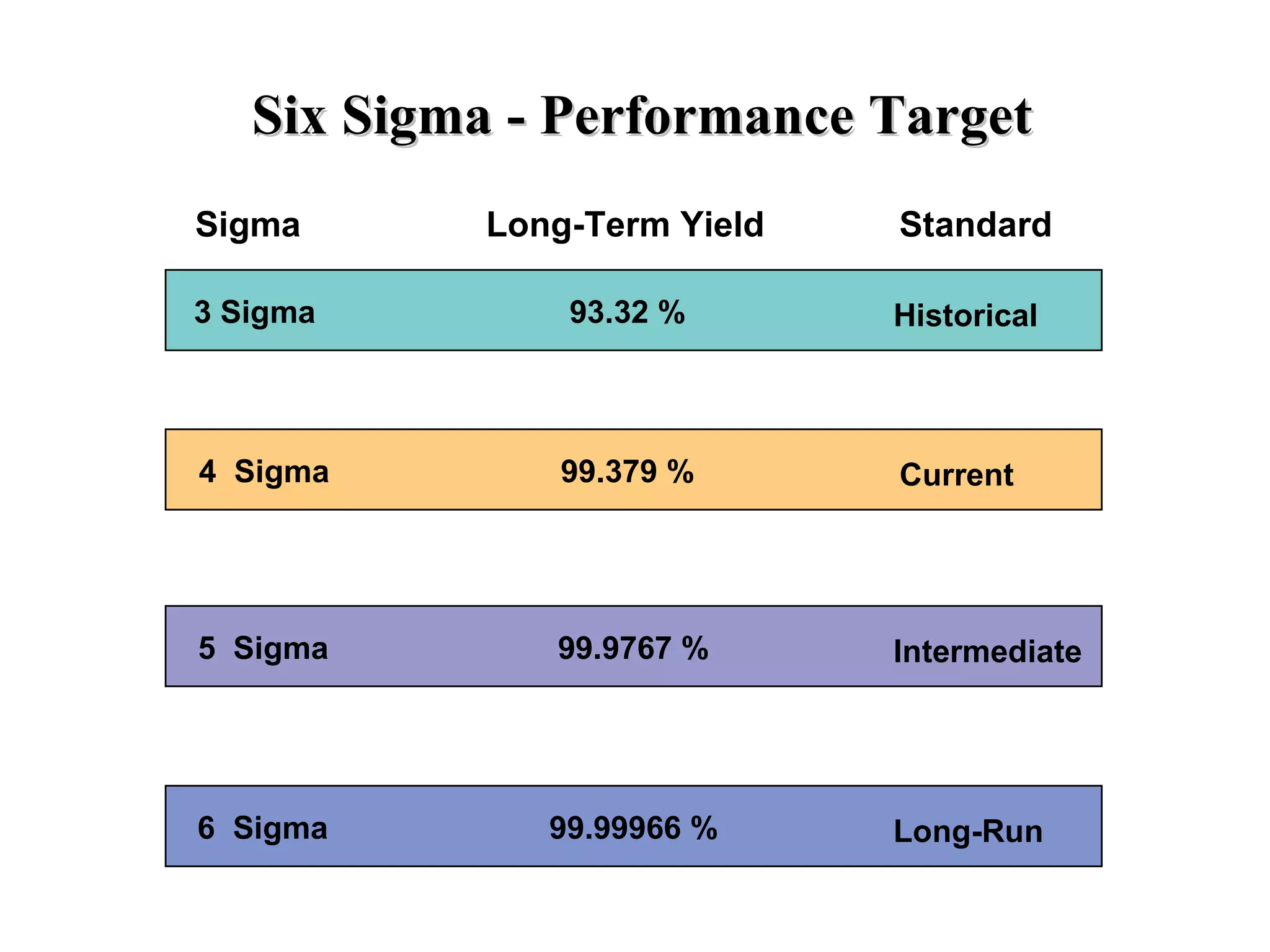

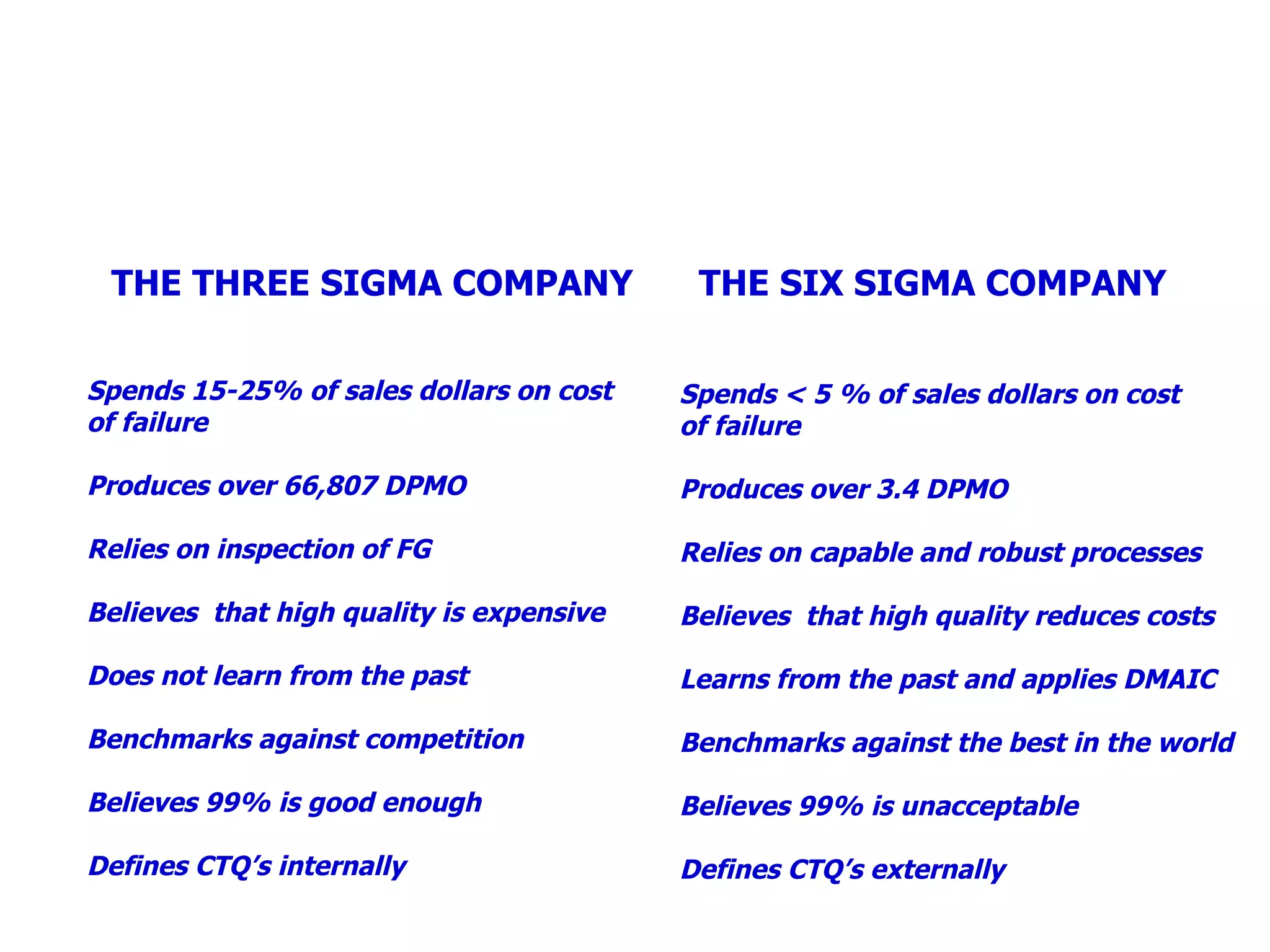

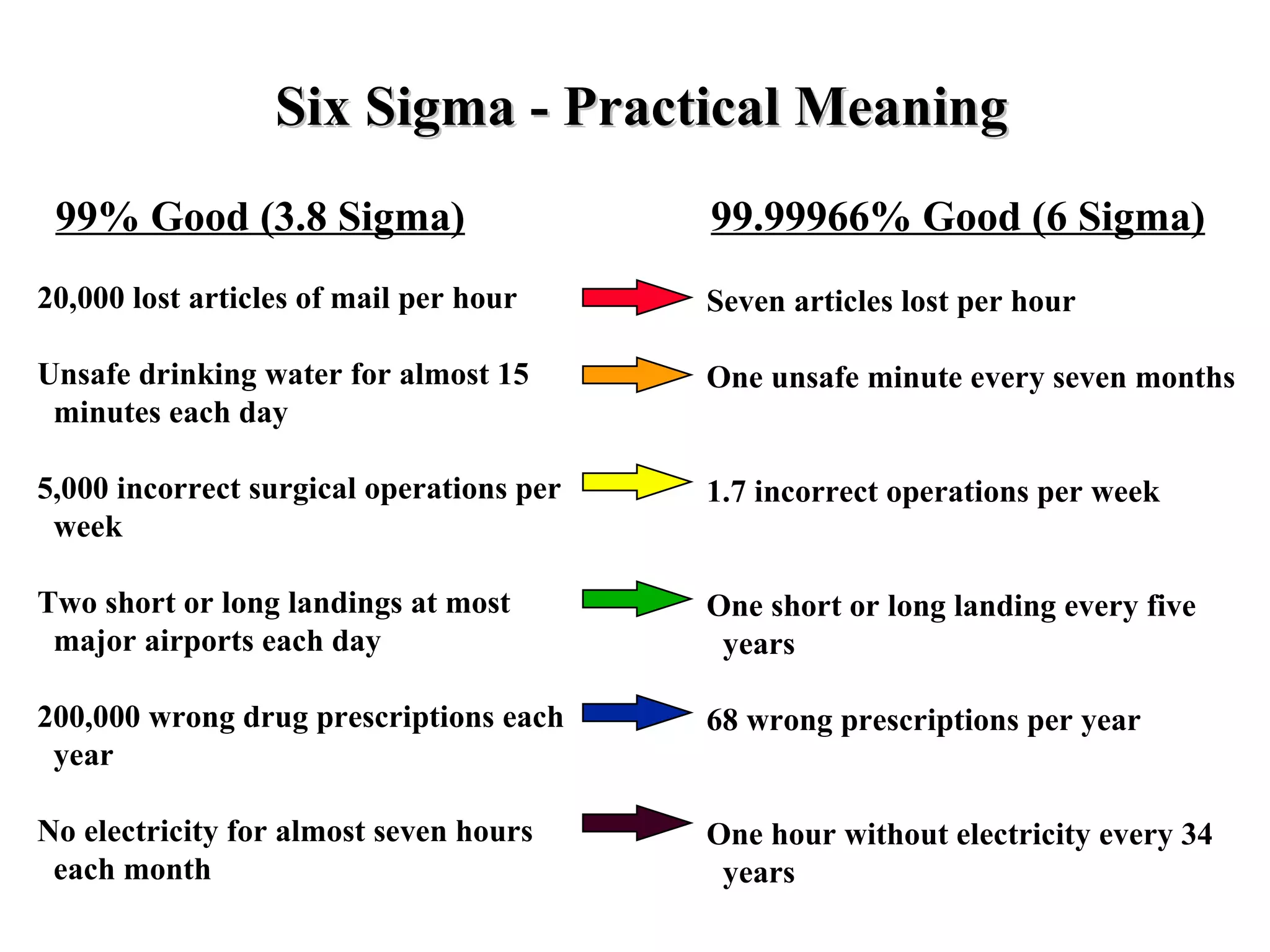

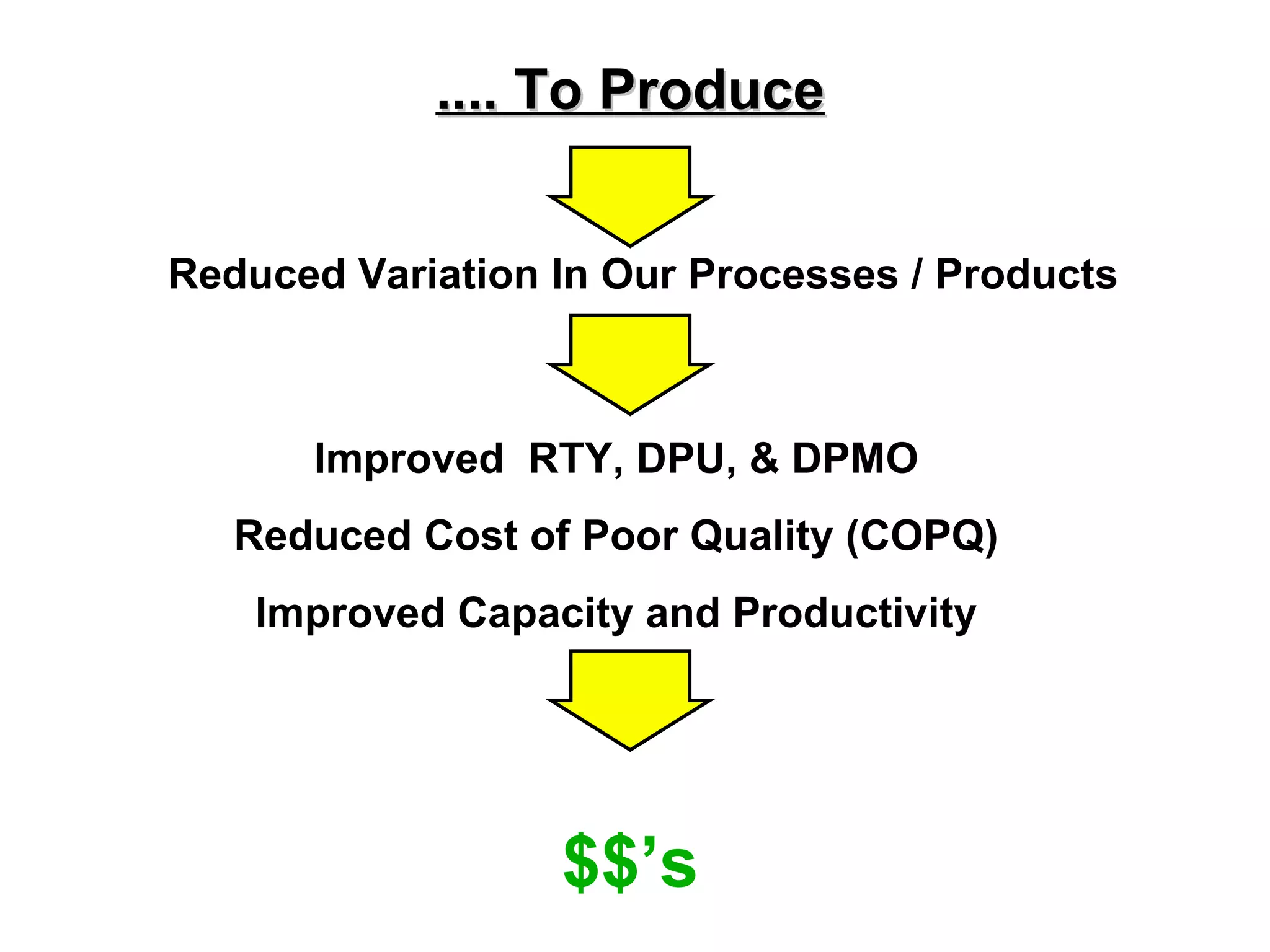

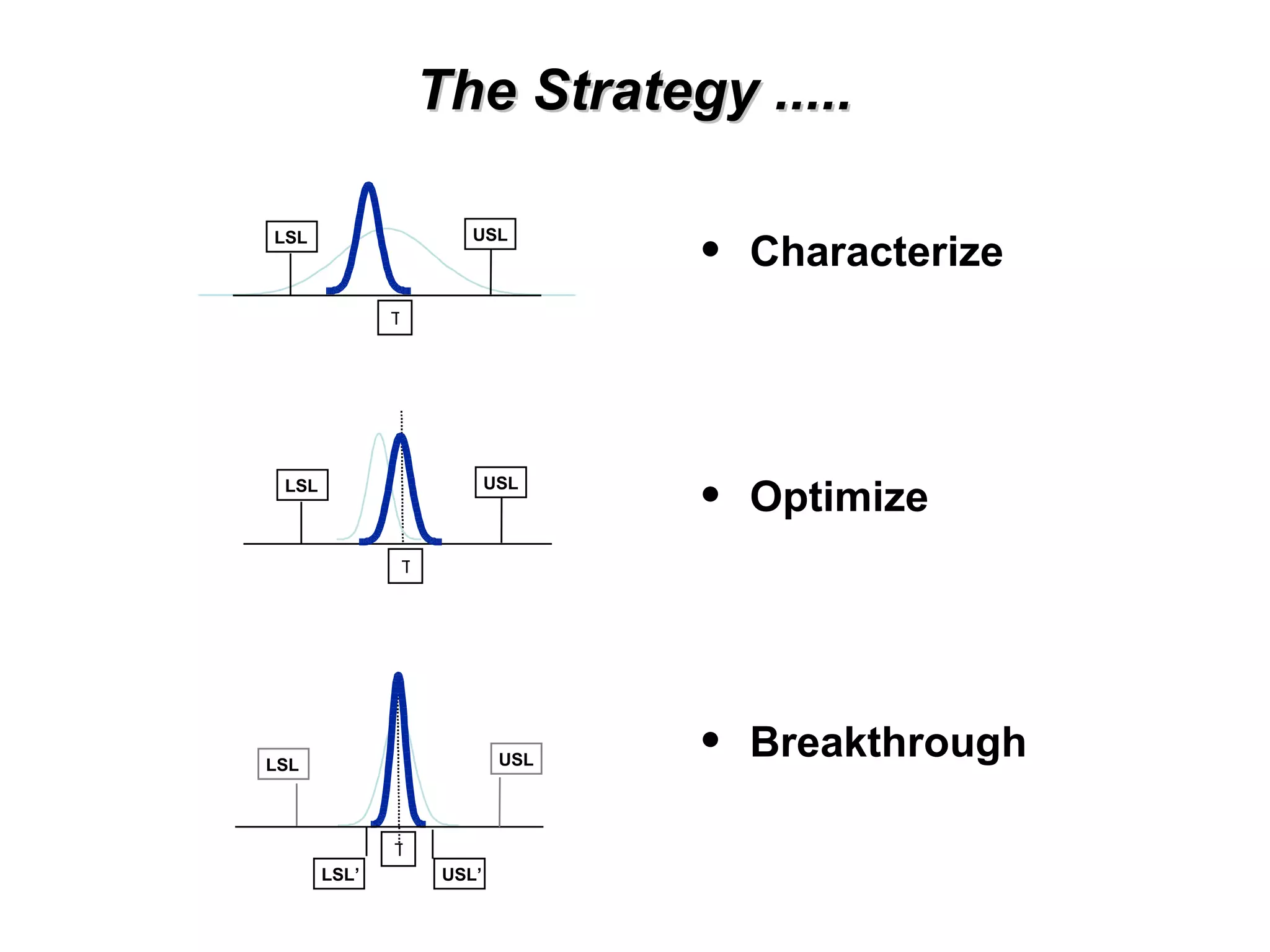

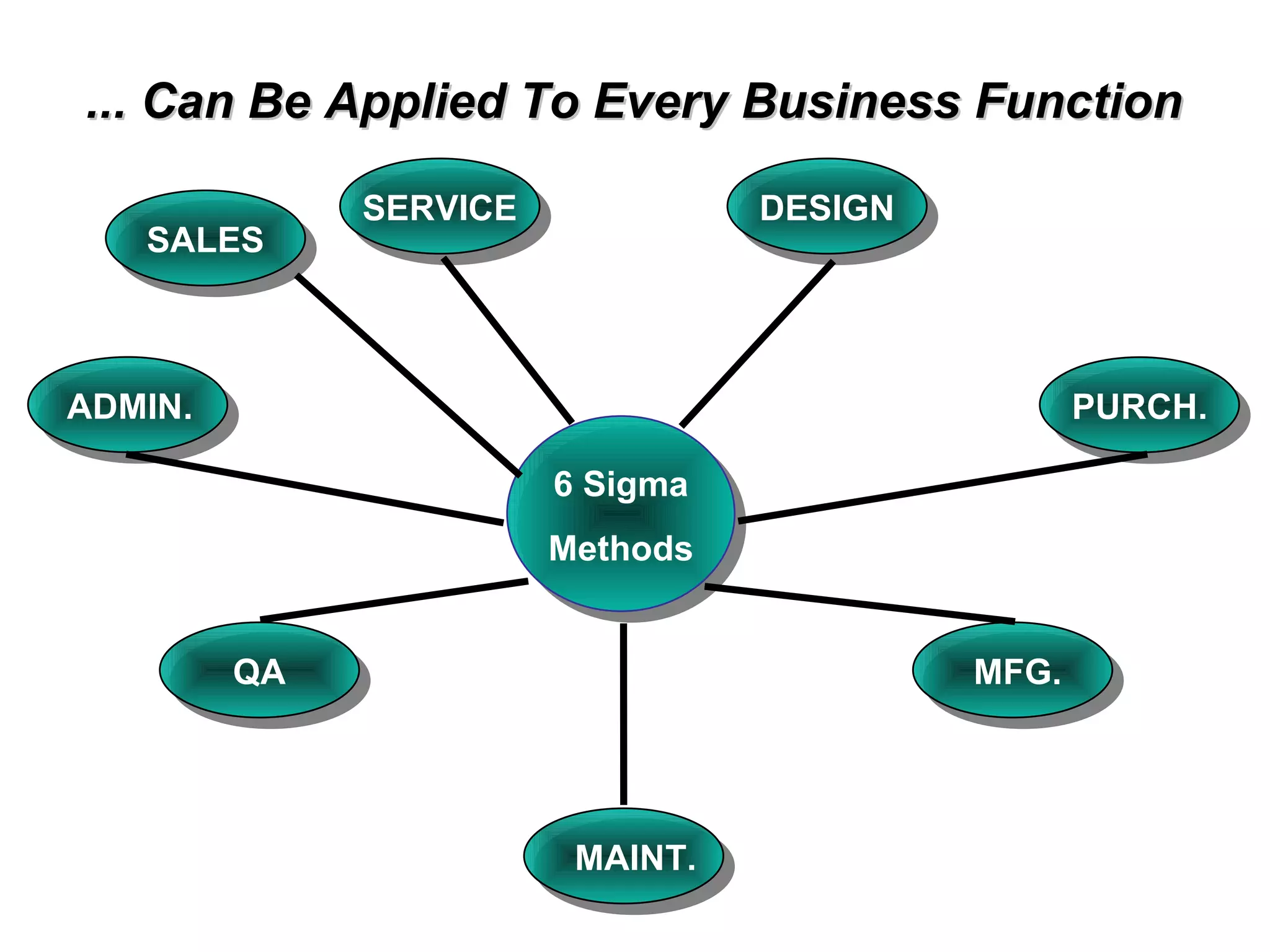

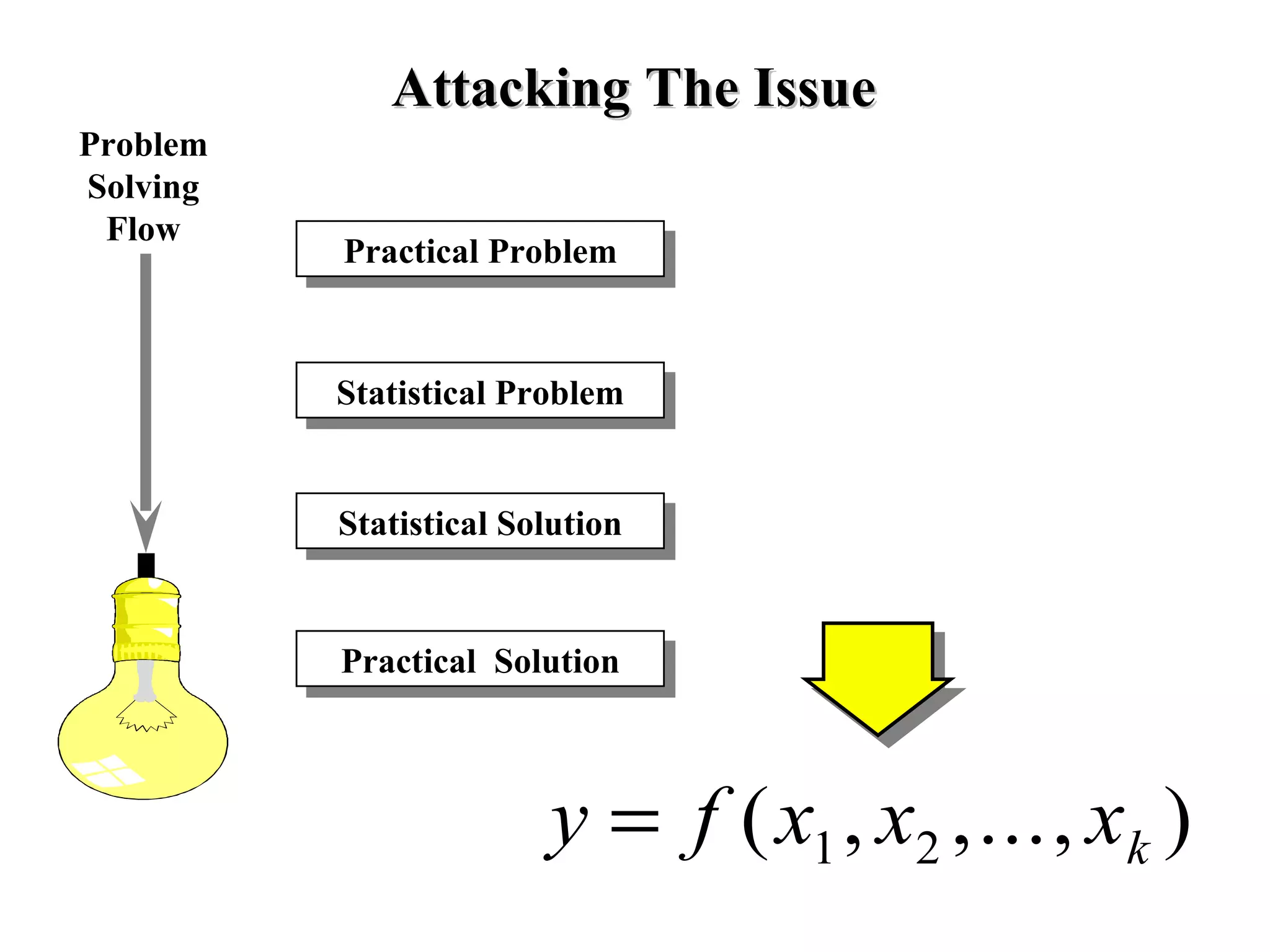

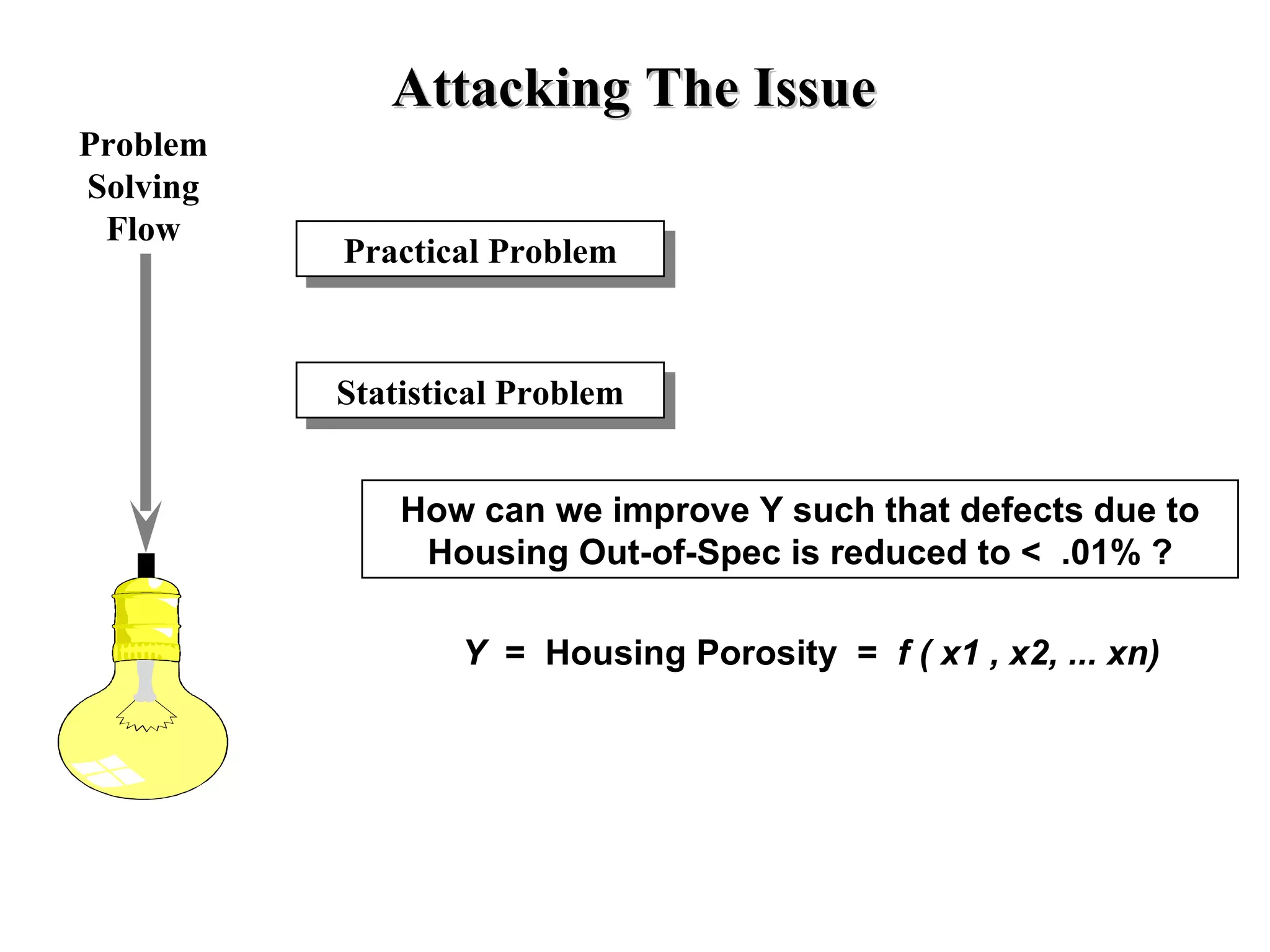

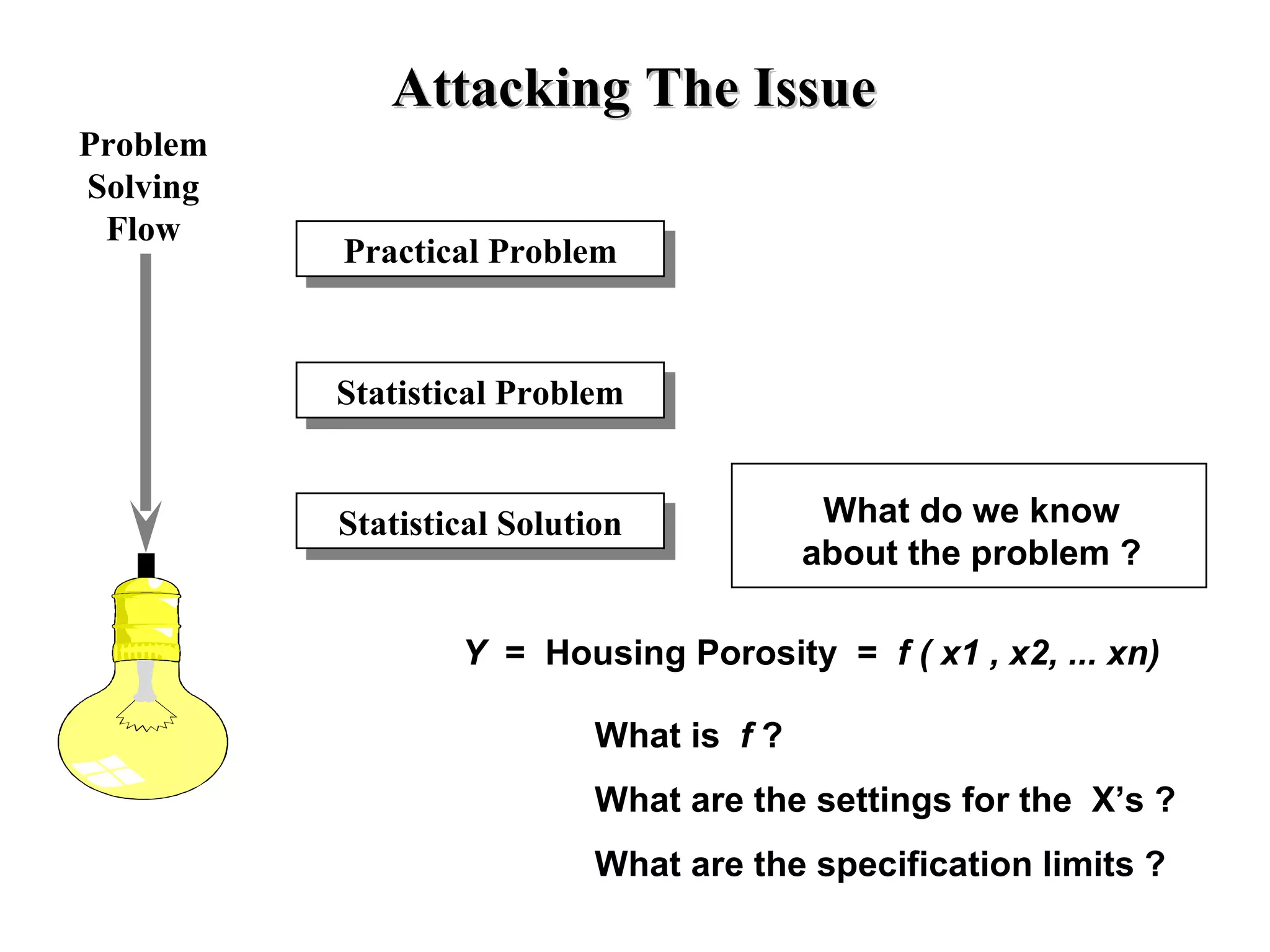

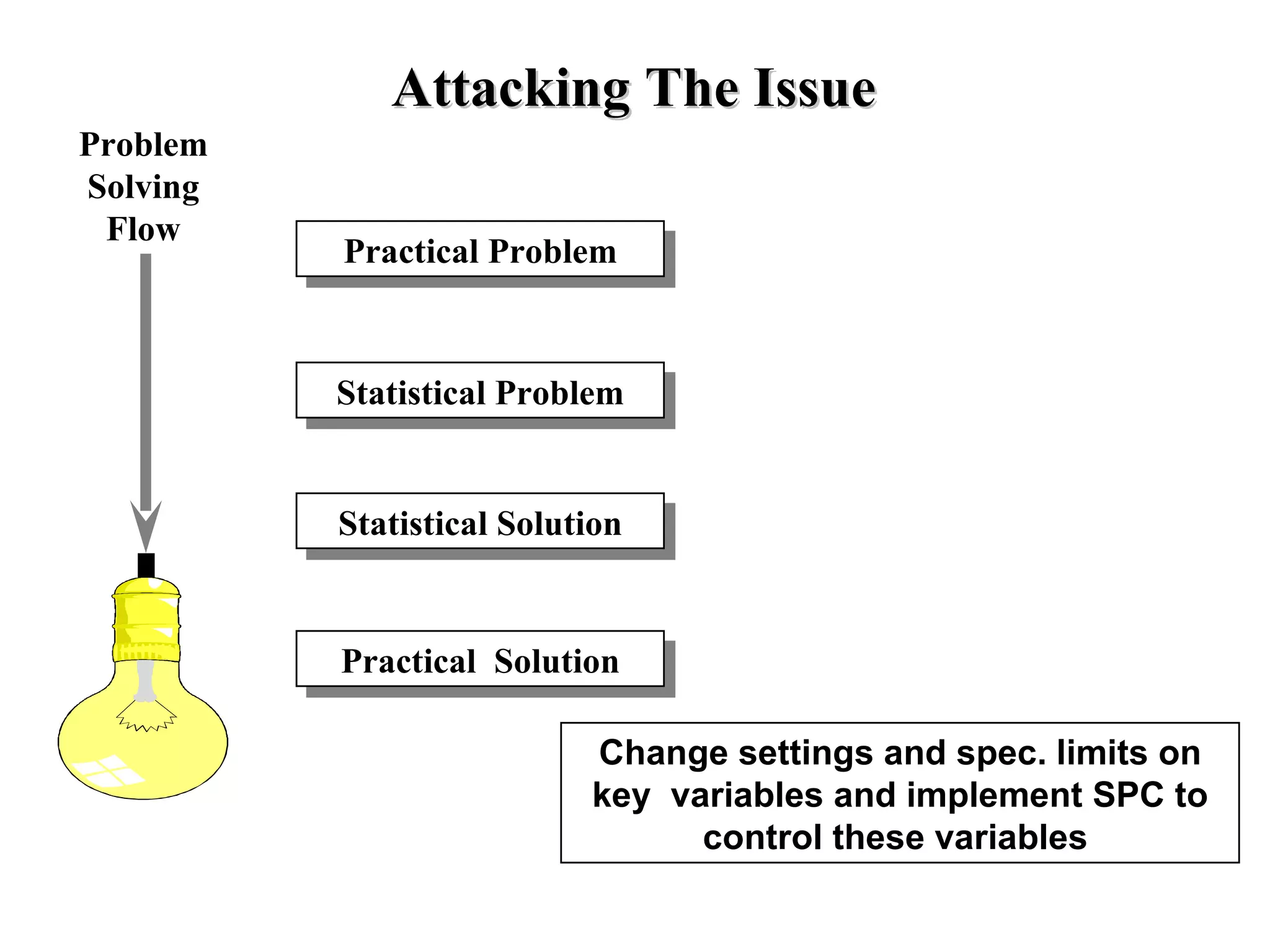

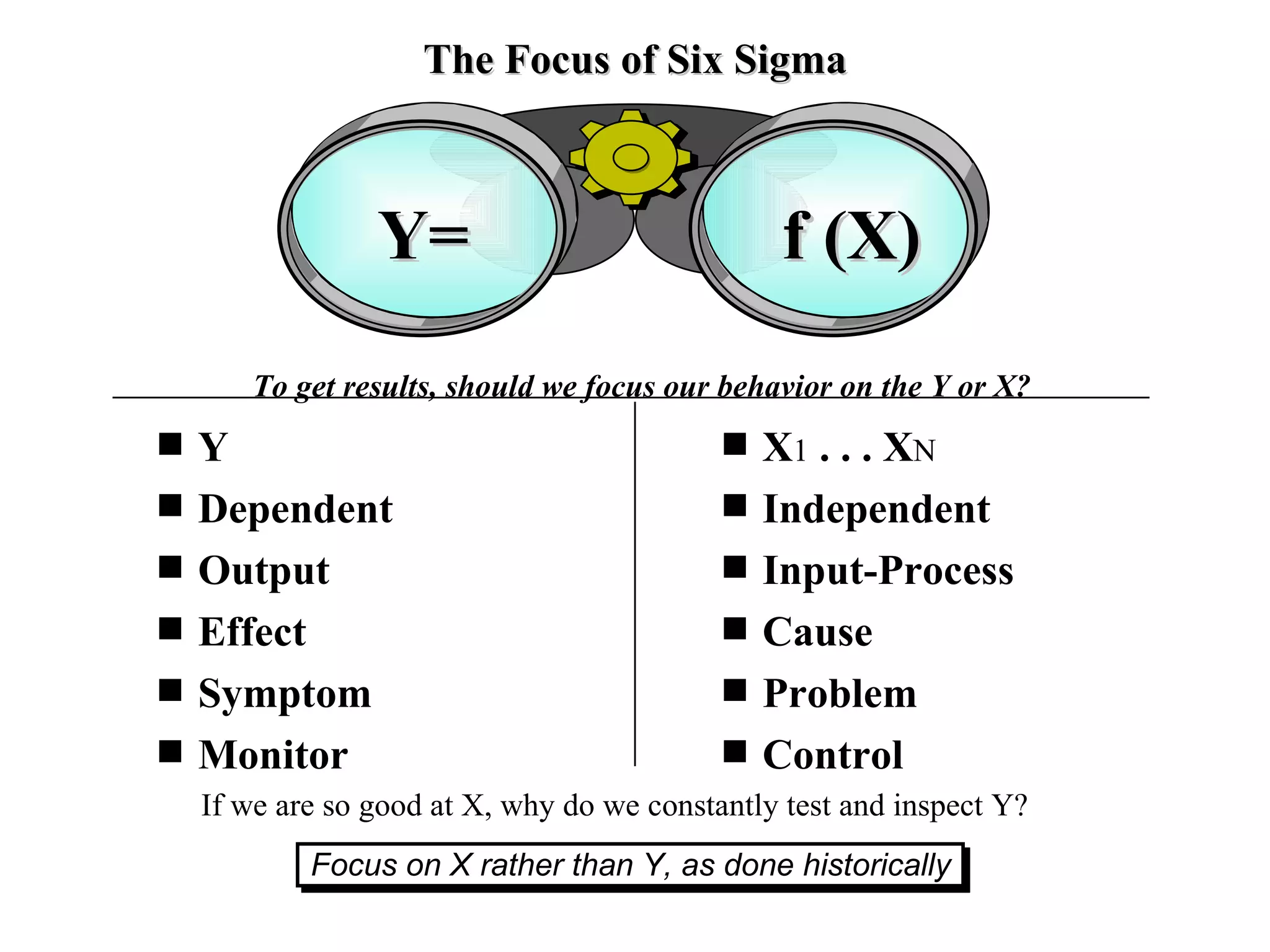

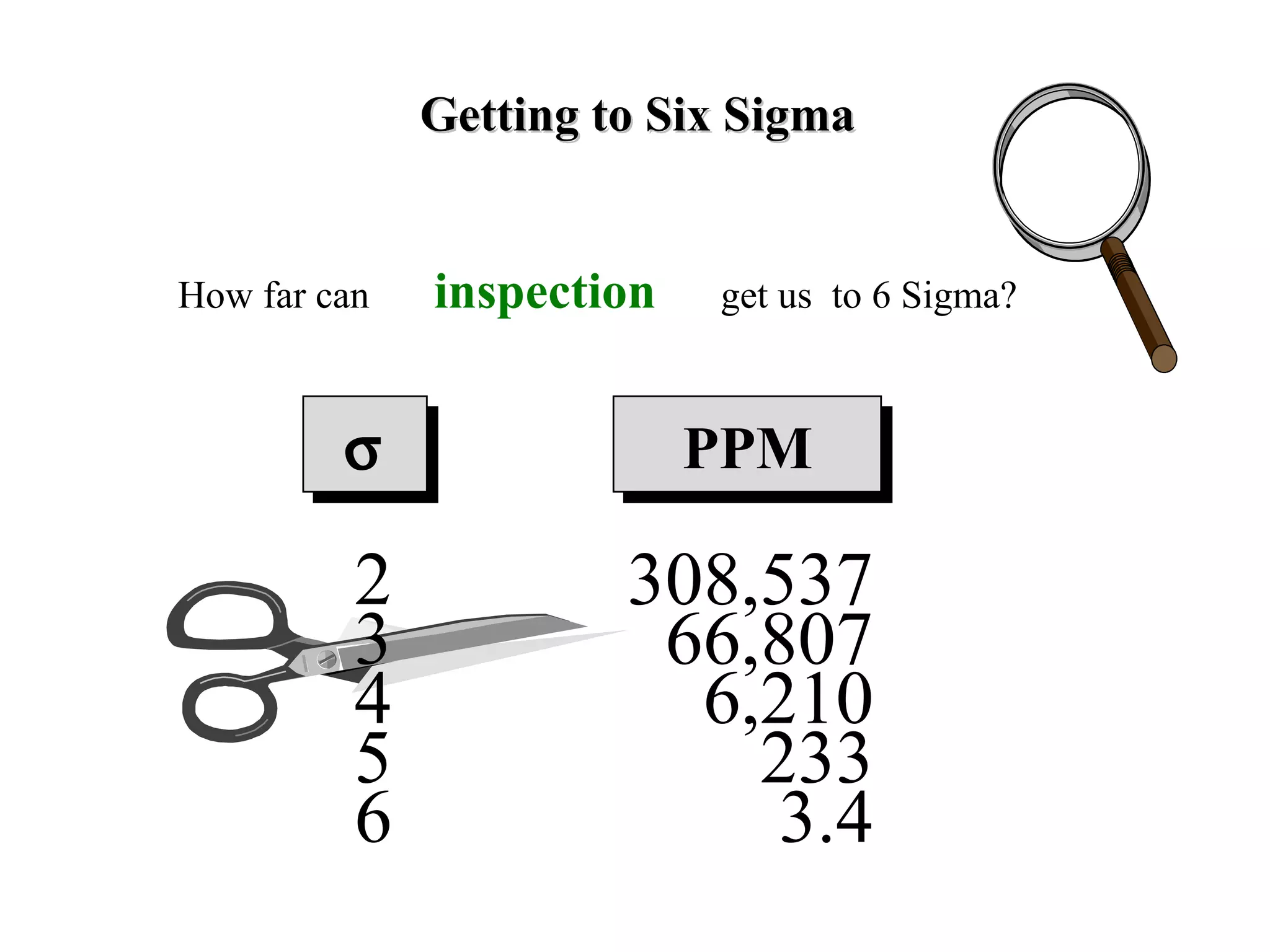

Six Sigma is a statistical methodology for improving business processes. It aims to reduce defects and variation in manufacturing and business processes. The goal of Six Sigma is to reduce defects to 3.4 defects per million opportunities. This can be measured using a metric called sigma, with 6 sigma representing a process operating with almost no defects. Key aspects of Six Sigma include defining critical customer requirements, using data and statistical analysis to determine sources of defects, implementing solutions to processes, and measuring their effectiveness.