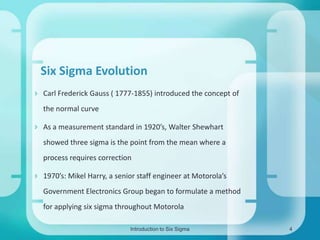

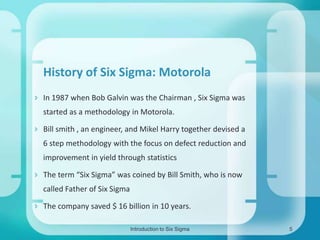

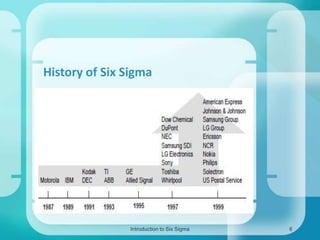

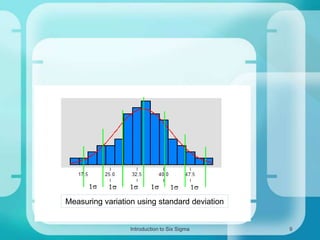

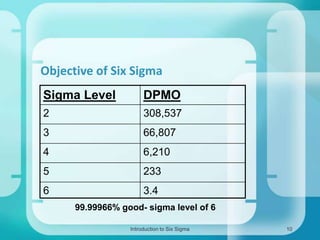

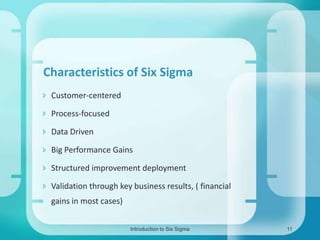

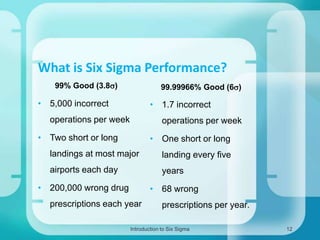

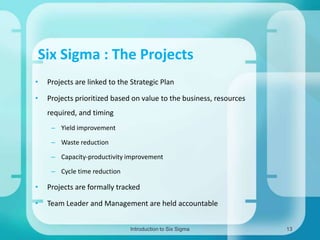

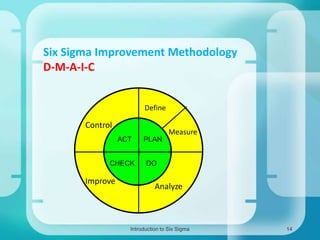

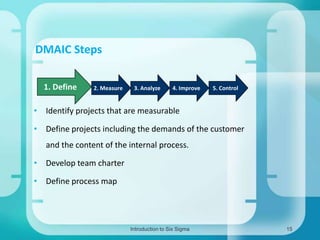

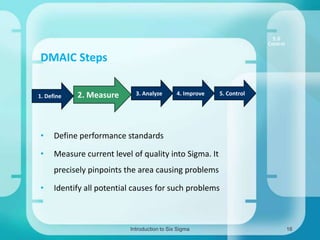

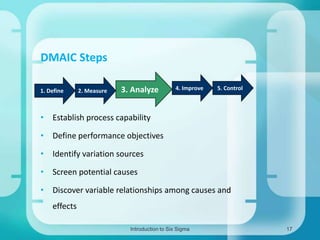

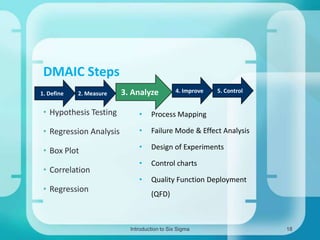

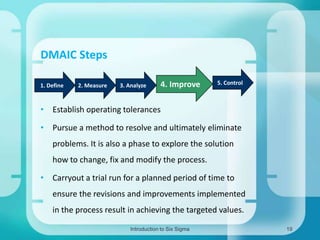

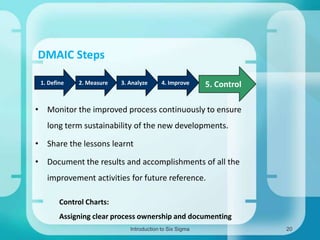

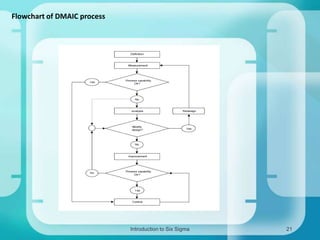

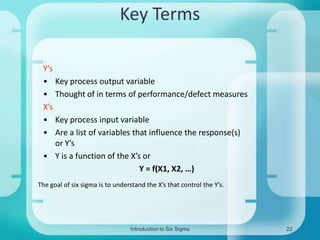

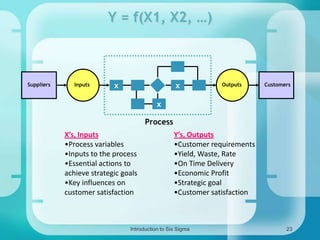

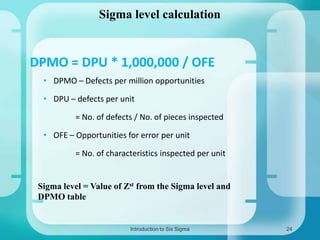

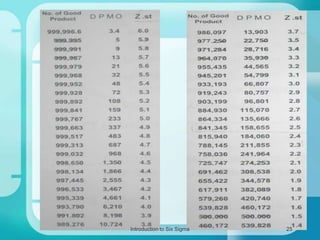

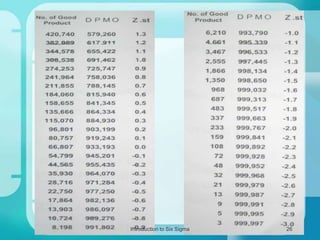

This document provides an introduction to Six Sigma. It defines Six Sigma as a methodology that aims for 3.4 defects per million opportunities. The document outlines the history and evolution of Six Sigma, from its origins in statistical process control to its development at Motorola in the 1980s. It describes the key aspects of Six Sigma, including its customer-focused approach and the DMAIC improvement methodology of Define, Measure, Analyze, Improve, and Control. The document explains Six Sigma's objective of achieving near-zero defect levels and illustrates the DMAIC steps and how they are used to identify and address issues in processes.