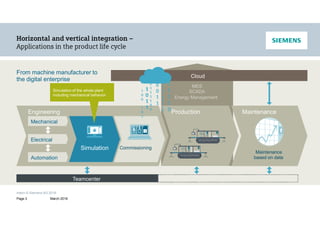

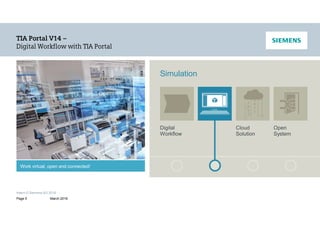

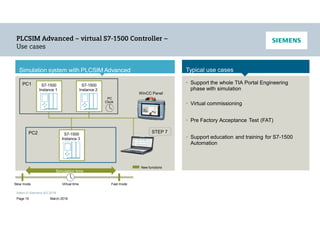

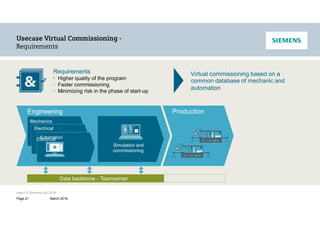

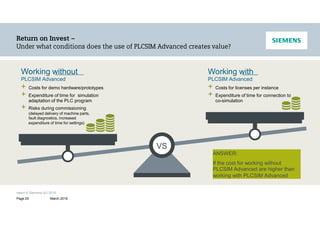

This document discusses PLCSIM Advanced, a new flexible simulation solution for TIA Portal V14. PLCSIM Advanced allows for simulation of the whole PLC in its application context using a virtual S7-1500 controller. It offers various features including multi-instance distribution, virtual time adjustment, and API interfaces for co-simulation. PLCSIM Advanced is presented as beneficial for engineering support, validation, training, and virtual commissioning by enabling simulation without hardware and reducing project risks and timelines.