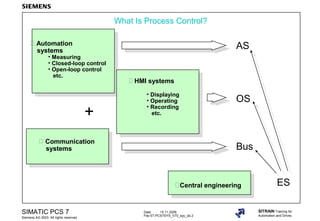

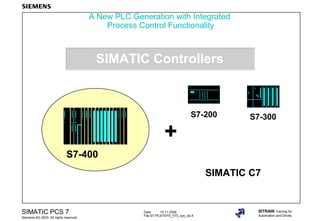

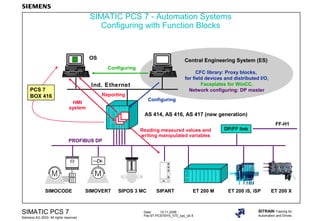

The document discusses SIMATIC PCS 7, an automation and process control system from Siemens. It describes the key components of process control systems, including automation systems, HMI systems, communication systems, and central engineering. It also outlines how PCS 7 provides seamless integration of older process control systems and enables configuration with function blocks. PCS 7 meets special requirements of the process industry through a top-down design methodology.