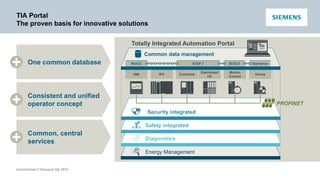

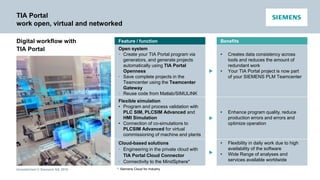

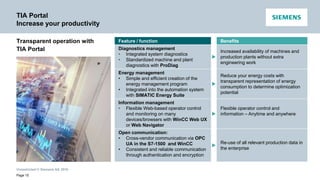

The TIA Portal is Siemens' software for industrial automation that enables total integrated automation. It provides benefits such as integrated engineering of controllers, HMIs, drives and other devices on a common platform. It allows for virtual commissioning and cloud-based engineering. Customers appreciate the time savings and increased productivity from features of the TIA Portal like integrated diagnostics, energy management tools, team-based engineering and automatic code generation. The TIA Portal supports customers in achieving Industry 4.0 goals like transparent operation, efficient workflows and reduced time to market.