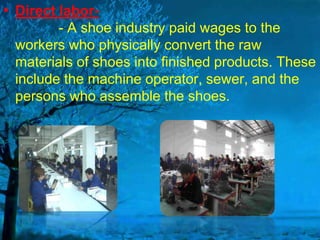

Shoes have evolved over time from simple sandals to complex designs that vary in style, material, and cost. The earliest known shoes date back 7,000-8,000 BC and were simple foot coverings to protect the feet. Contemporary shoes can be made of expensive materials through complex construction processes. A shoe industry incurs direct costs for labor, materials like leather and laces, and manufacturing overhead including indirect labor, utilities, supplies, and other costs like taxes, insurance, and equipment maintenance.

![evidence of the earliest footwear due to the highly

perishable nature of early shoes. By studying the

bones of the smaller toes (as opposed to the big

toe), it was observed that their thickness

decreased approximately 40,000 to 26,000 years

ago. This led archaeologist to deduce that wearing

shoes resulted in less bone growth, resulting in

shorter, thinner toes.[5] These earliest designs

were very simple in design, often mere "foot bags"

of leather to protect the feet from rocks, debris,

and cold. They were more commonly found in

colder climates.](https://image.slidesharecdn.com/shoesindustry-131201231421-phpapp01/85/Shoes-industry-4-320.jpg)