The document discusses shoe lasts, which are molds used to shape shoe uppers to size and fit. Key points:

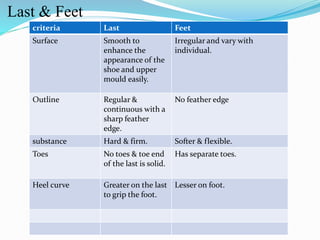

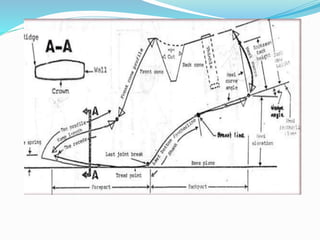

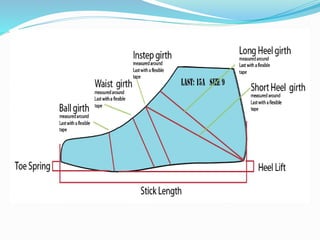

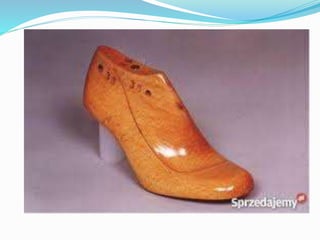

- Lasts are molds that shoe uppers are shaped on and retain the 3D shape of the finished shoe. They help attach the insole and sole to the upper.

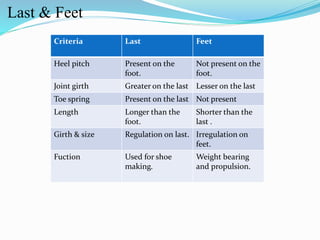

- Lasts are designed based on foot shape but also fashion trends and construction type. They are longer and have a greater girth than feet.

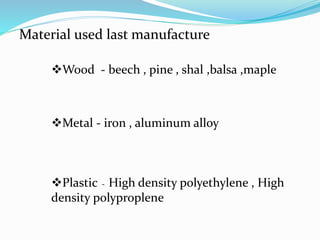

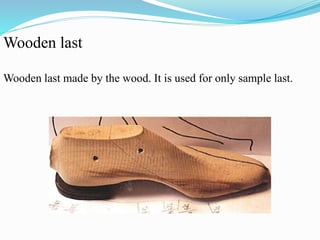

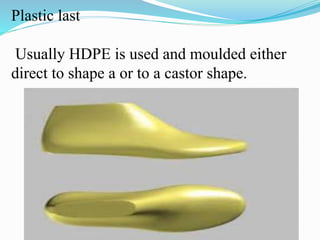

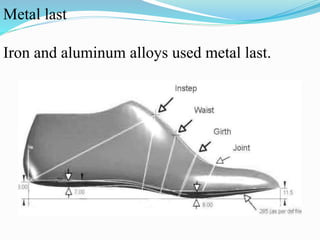

- Different materials are used to make lasts including wood, metal, and plastics like HDPE.

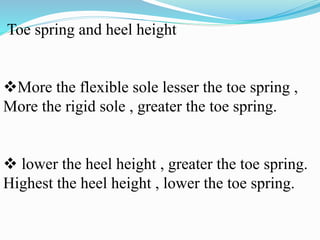

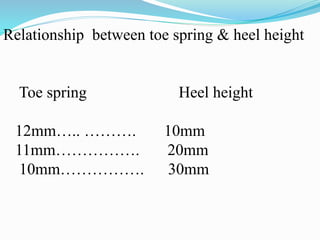

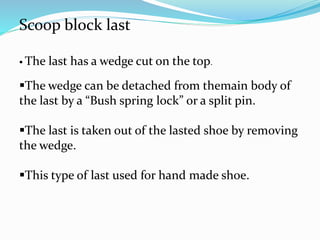

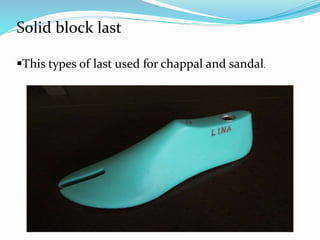

- Toe spring and heel height on lasts are designed based on shoe flexibility and intended use. Various types of lasts also exist like solid block, hinged,