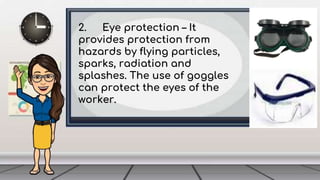

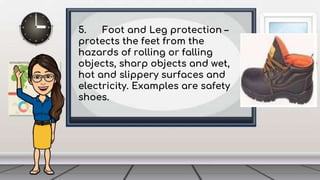

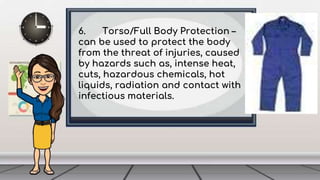

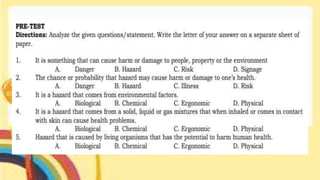

This document provides an overview of hazards and risks in the workplace. It defines a hazard as any situation or object that could cause harm. Hazards are classified as physical, chemical, biological, or ergonomic. The document also discusses personal protective equipment (PPE) and gives examples of PPE used to protect different parts of the body, such as safety hats for the head, goggles for eyes, ear protection, gloves for hands, safety shoes for feet, and respiratory equipment. The overall goal is to educate about differentiating hazards from risks, evaluating risks in the workplace, properly using PPE, and following safety procedures.

![Objectives:

a. differentiate hazard from risk;

b. evaluate hazard and risk in the workplace;

c. use Personal Protective Equipment [PPE]

properly; and

d. observe safety procedures while at work.](https://image.slidesharecdn.com/las3hazardsandrisks-240309013338-ea0c2182/85/Shielded-Metal-Arc-Welding-Lesson-Hazards-and-Risks-8-320.jpg)