Embed presentation

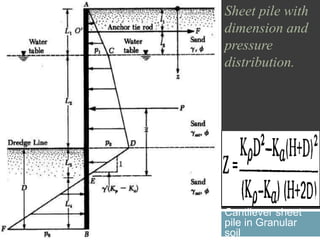

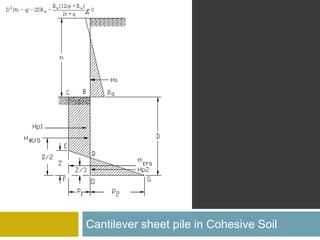

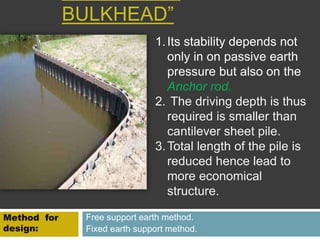

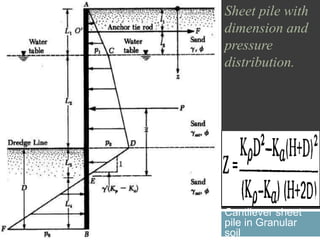

Sheet pile walls are constructed by driving prefabricated sheet pile sections into the ground to form retaining structures for earth and water. Sheet piles have advantages over other materials like high resistance to stresses, light weight, reusability, and long service life above or below water. They are constructed by laying out and interlocking sheet pile sections and driving them into the ground. Disadvantages include the inability to reuse sections permanently and difficulties installing in soils with debris.