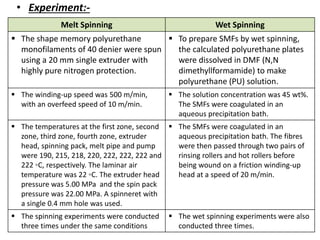

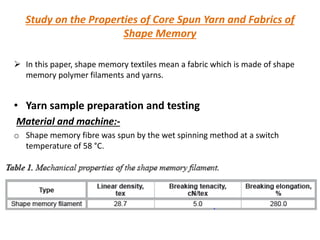

This document discusses shape memory polymers, specifically shape memory polyurethanes (SMPUs). It summarizes that SMPUs can recover from deformations up to 400% through heating above their glass transition temperature, due to their network structure of hard and soft blocks. It then describes experiments making shape memory fibers through both melt spinning and wet spinning. The melt spun fibers had higher strength and shape memory effects than wet spun fibers due to better phase separation in the melt spinning process.