Session 3 - Michael Berna Indiana Logistics Summit 2012

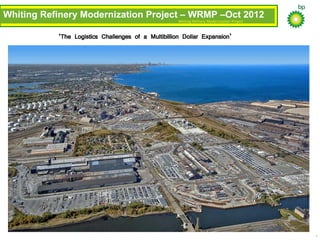

- 1. Whiting Refinery Modernization Project Whiting Refinery Modernization Project – WRMP –Oct 2012 1 ‘The Logistics Challenges of a Multibillion Dollar Expansion’

- 2. Whiting Refinery Modernization Project BP Whiting Business Overview • The refinery began operation in 1890 • The 6th largest refinery in the U.S. with 413,000 barrels per day of crude distillation capacity • Supplied by a network of pipelines that provides access to 3 distinct crude markets • Over 15 millions gallons per day of transportation fuels produced and shipped via 8 pipelines • Transportation fuel marketed at a network of terminals across 8 states • One of the largest producers of asphalt in the U. S. • Other products distributed across the country by pipeline, truck, rail and barge • Existing refinery employs about 1,850 BP employs plus contractors for capital projects, TARs, etc. 2

- 3. Whiting Refinery Modernization Project WRMP competitively repositions Whiting Refinery • Modernizes the Whiting Refinery with world scale assets • Processes incremental heavy sour and high TAN crude as substitute for light, sweet crude • Selective debottlenecking of fuels production Status • Completion is during second half of 2013 • Greater than 75% complete with on-site construction • 28 million hours worked without a day-away from-work injury 3

- 4. Whiting Refinery Modernization Project Key Aspects of the Project BP Confidential 4 4

- 5. Whiting Refinery Modernization Project 12 Pipestill Super Module at dock area Old Crude and Vacuum Towers New Vacuum Tower One of the worlds’ largest New Crude Tower 5

- 6. Whiting Refinery Modernization Project 12 Pipestill • All modules and major equipment set August 2011 October 2012 6

- 7. Whiting Refinery Modernization Project Coker • All modules and major equipment set August 2011 August 2012 7

- 8. Whiting Refinery Modernization Project Gas Oil Hydro-Treater •All modules and major equipment set August 2011 August 2012 8

- 9. Whiting Refinery Modernization Project Sulfur Recovery Facilities August 2011 August 2012 9

- 10. Whiting Refinery Modernization Project OSBL Facilities Overall OSBL Scope • Several OSBL sub-projects significantly modernize the refinery OSBL Cooling Tower #8 • 90,000 gallons per minute of water circulation 10

- 11. Whiting Refinery Modernization Project Fully automated Coker gantry crane Coke barn holding 5 days product produced at 6,000 tons/day Coker gantry crane and holding barn 11

- 12. Whiting Refinery Modernization Project Logistics Challenges on a Mega Project Scale Construction Statistics • 800 modules and vessels • 1,200 pieces of equipment • 380 miles of pipe • 50,000 tons of steel • 1325 miles of wire and cable (distance from Chicago to Santa Fe, NM) • 15,000 concrete truck deliveries • 95,000 truckload deliveries • 14,000 piles to be driven • 200 material deliveries per day • 9,000+ Staff/Craft on ‘One Whiting’ site at peak 12

- 13. Whiting Refinery Modernization Project Fluor (EPC) ________________________ GOHT ________________________ OSBL ________________________ 12 PS Jacobs (EPC) _________________________ Sulfur (SRC) Foster Wheeler (EPC) COKER AG&P (Modules) Philippines JAT (Jacobs) (Modules) Charleston, SC Dii (Modules) Louisiana Barges Mammoet Major Engineering Equipment Mammoet to point of final Whiting location Mammoet Site Placement (Jumbo via Foster Wheeler) International Shipment All Equipment is FAS International Shipment Truck & Rail Non-Modular Material/Equipment Whiting RefineryModernization ProjectKey Material and Logistics Pattern

- 14. Whiting Refinery Modernization Project Logistics – Global to Last Mile • Vessels − USA − Spain − Italy − Germany − Japan − Korea • Shipped by − Jumbo Ship − Ocean Barge − Lake Barge − Hopper Barge − Freight − Rail 14

- 15. Whiting Refinery Modernization Project Logistics – Global to Last Mile • Modules – 600 − New Iberia, La − Goose Creek, SC − Batangas, Phillipines • Shipped by − Jumbo Ship − Ocean Barge − Lake Barge − Deck Barge − Hopper barge 15

- 16. Whiting Refinery Modernization Project Shipping Offloads – Vessels / Modules • Via St Lawrence Seaway and Great Lakes − Montreal, Canada − Port of Indiana − IPMT Dock Facility • Via Mississippi and Illinois Rivers − Port Allen, SC − New Iberia, La − IPMT Dock Facility 16

- 17. Whiting Refinery Modernization Project 12 PS Vacuum Tower on Deck Barge

- 18. Whiting Refinery Modernization Project IPMT Dock Facility • 2 Heavy Lift Berths and a Roll On / Roll-Off Ramp − 400T crane for Hopper Barge offloads and SPMT Transporters for Deck Barge Roll Offs 18

- 19. Whiting Refinery Modernization Project IPMT Dock Facility–N–54 Acres, S–17+ Acres w/Roll Off Ramp – Aug 2008 19

- 20. Whiting Refinery Modernization Project IPMT Dock Facility – N – 54 Acres, S – 17+ Acres w/Roll Off Ramp – Nov 2010 20

- 21. Whiting Refinery Modernization Project IPMT Dock Facility – N – 54 Acres, S – 17 Acres w/Roll Off Ramp – OCT 2012

- 22. Whiting Refinery Modernization ProjectEngineering, Review and 3rd Party Asssurance • Major Lifts for loading, offloading, transport to site or lifting at site were − Developed by EPC or Mammoet − Stamped by Indiana PE and reviewed by Independent 3rd party, Lowther Rolton − Witnessed by 3rd Party Heavy Lift experts from Santis or Lowther Rolton − Reviews performed with Project Lift committees as additional assurance − Several Thousand Engineered Lifts made at site alone • Logistics required to keep engineering and paperwork flowing without impacting construction

- 23. Whiting Refinery Modernization Project12 PS Vacuum Tower Lift

- 24. Whiting Refinery Modernization Project Heavy Haul Road Layout • All 34KV power lines moved underground • 138KV Transmission Lines powered down by NIPSCO for Transports over 50’ tall • Traffic Signals replaced with Swivel design • 4 K-Rated Gates installed at Refinery perimeter • New Heavy Haul roads built within refinery • Police escort from Barge facility to HH Gates • Adjacent businesses and surrounding municipalities alerted prior to Transports.

- 25. Whiting Refinery Modernization Project Heavy Haul Roads and Transports • 12 PS Fractionator 25

- 26. Whiting Refinery Modernization Project Coker Module Transport

- 27. Whiting Refinery Modernization Project Site Coordination • Daily Meetings with Security, Emergency Response, Fire department, Pillar Logistics Leads, WBU Turnaround and Projects teams • Utilize Live Map, Monthly Aerial photos and Smart Boards to visualize and plan − Road Closures and Emergency response Impacts − Heavy Haul Transports − Major Crane Lifts and Heavy Equipment locations − Other Site Impacts due to SIMOP’s • Weekly Logistics Meeting – Longer range view − Staff and Craft Housing − Craft Parking and Bussing – 9000+ Craft at peak, 9 Parking Lots − Water distribution – 2000/day 27

- 28. Whiting Refinery Modernization Project 4 Warehouses 850K sq/ft and 13 Lay down Yards – 203 Acres

- 29. Whiting Refinery Modernization ProjectOne Whiting Parking – 9 new Lots required

- 30. Whiting Refinery Modernization Project One Whiting Bus and Shuttle Routes/Schedule

- 31. Whiting Refinery Modernization Project One Whiting Snow Removal

- 32. Whiting Refinery Modernization Project 47 Acres, H2 Plant, Standard Avenue Reroute – Aug 2008 32

- 33. Whiting Refinery Modernization Project 47 Complex, H2 Plant, Standard Avenue Reroute – OCT 2012

- 34. Whiting Refinery Modernization ProjectLR13000 – 3000T Crawler Crane • One of Largest Crawler Cranes in the World • Delivered from Germany by Jumbo Ship to Port of Indiana • Offloaded in over 200 pieces • Proof Tested at 3400T • Crawler tracks over 11’ tall • Tubing on Boom and Mast is 2” Thick • Redundant State of the Art Control systems • What could you do with this crane and how would that help you?

- 35. Whiting Refinery Modernization Project 12 PS Construction 35

- 36. Whiting Refinery Modernization Project Coke Drum Lifts 36