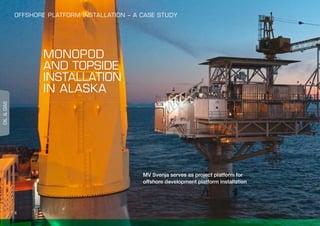

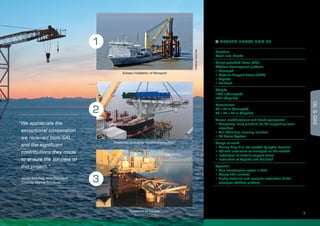

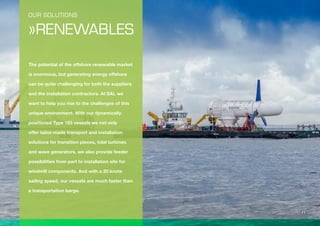

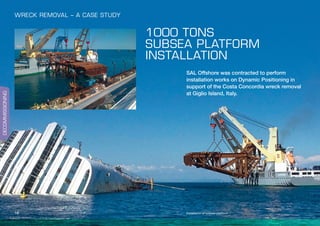

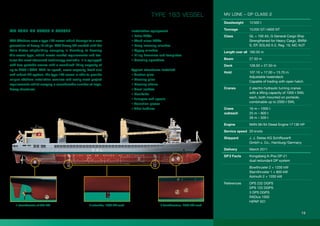

This document summarizes the offshore installation and decommissioning solutions provided by SAL Offshore. It describes their dynamically positioned vessel, the MV Lone, which is used to transport and install subsea structures, mooring systems, and components for oil & gas and renewable energy projects. Case studies are provided for installations in Alaska, India, the Mediterranean, and New Zealand. The company also assists with wind turbine and tidal turbine installation, as well as decommissioning work like the Costa Concordia wreck removal project.