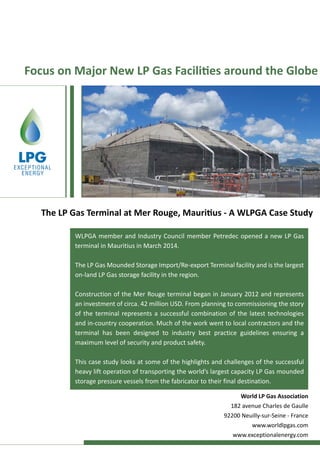

1. Petredec opened a new 15,000 metric ton LP Gas terminal in Mauritius in March 2014, representing an investment of $42 million.

2. Three 5,000 tonne LP Gas vessels were transported over 8,200 km by ship from Italy to Mauritius, then offloaded and installed at the terminal site in just eight days through careful planning and coordination.

3. The new terminal aims to transform Mauritius into a regional LP Gas hub and allows Petredec to more efficiently supply Mauritius and other East African markets in the future.