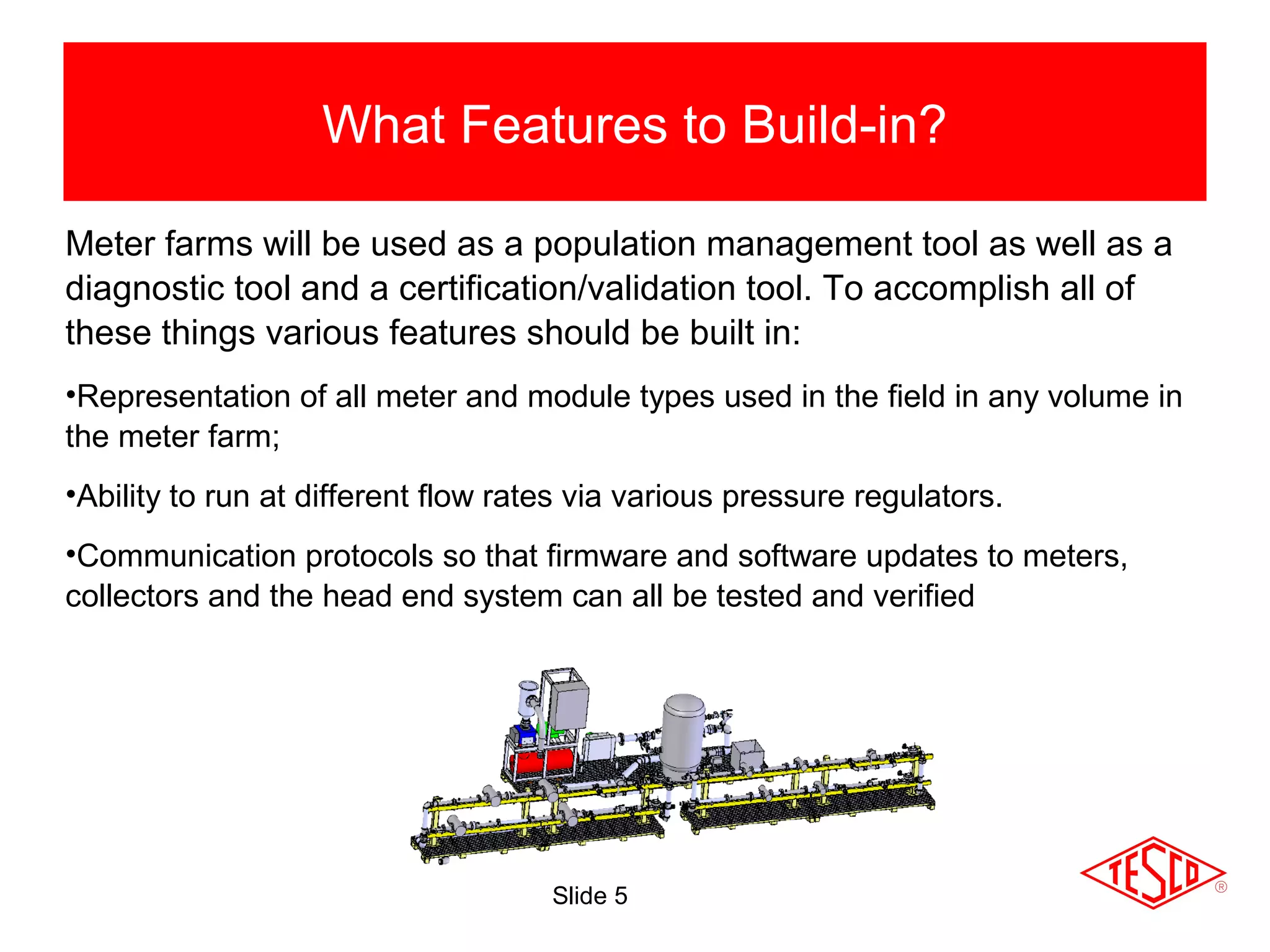

The document outlines the concept and applications of gas meter farms, which serve as tools for managing and testing advanced metering infrastructure (AMI) meter populations. It discusses the setup, features, and uses of meter farms before, during, and after deployment, emphasizing their role in performance validation, diagnostics, and acceptance testing. The importance of meter farms in contributing to the stability and accuracy of metering systems is highlighted, particularly in managing technological changes and ensuring system reliability.