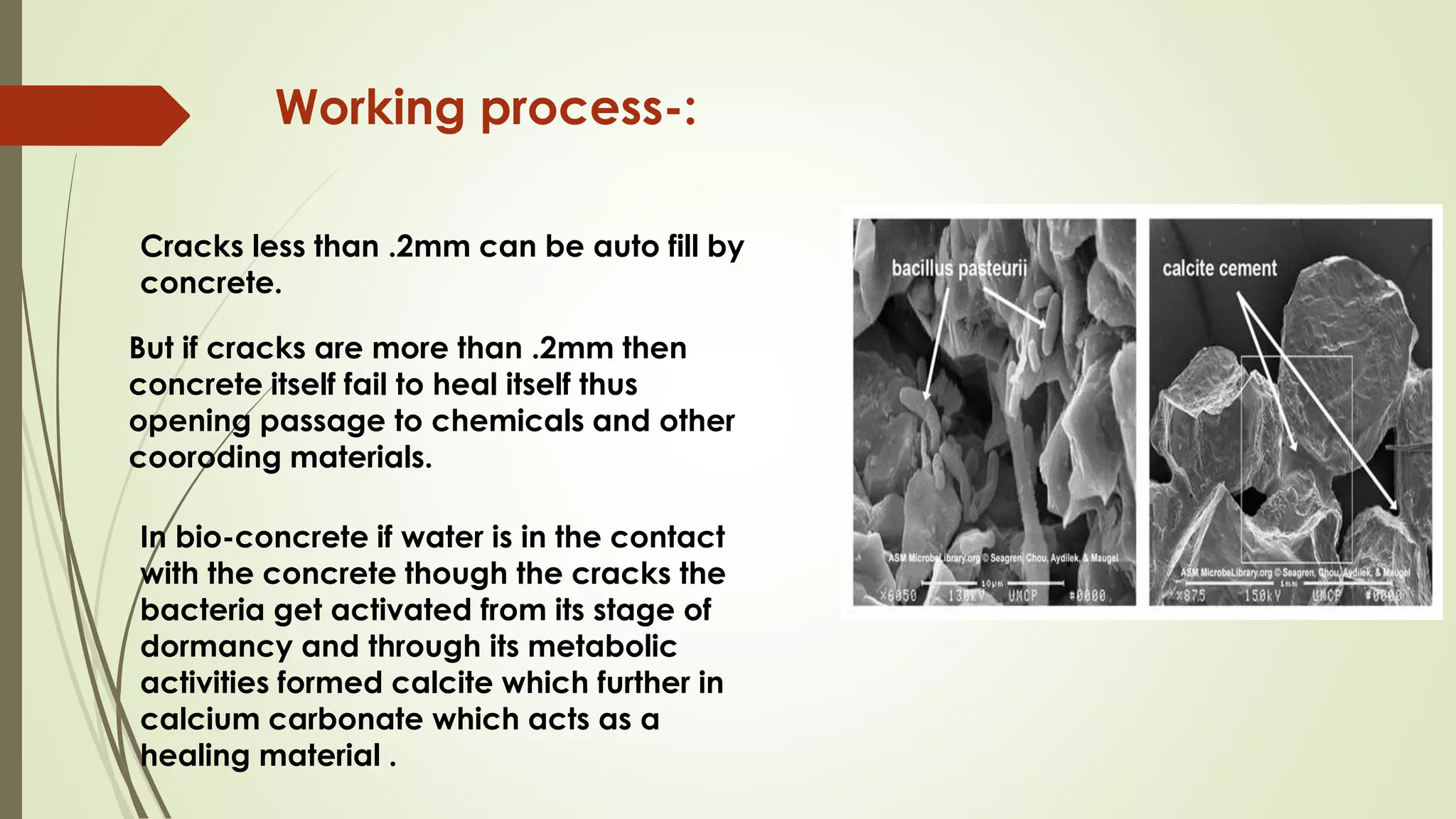

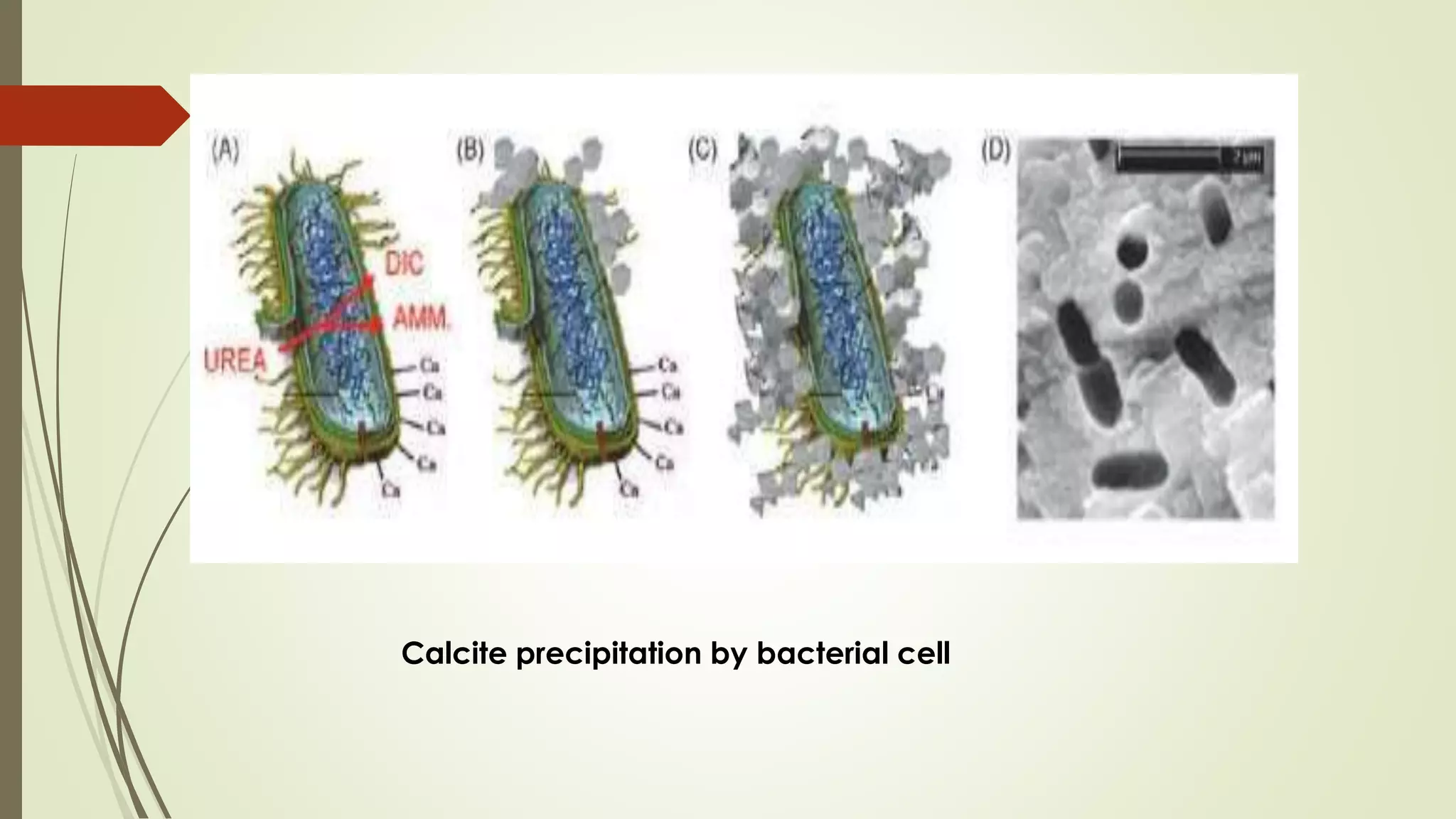

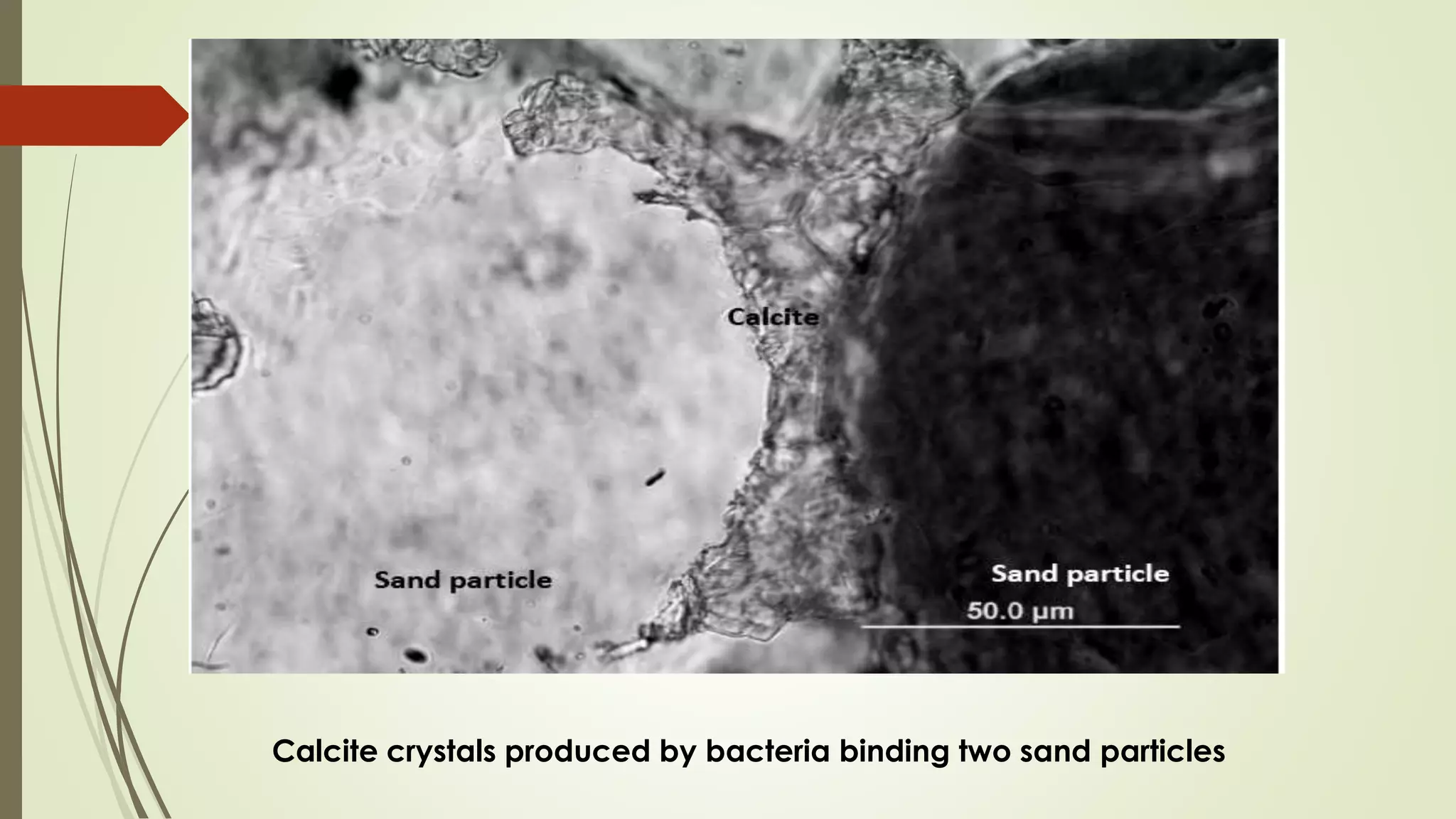

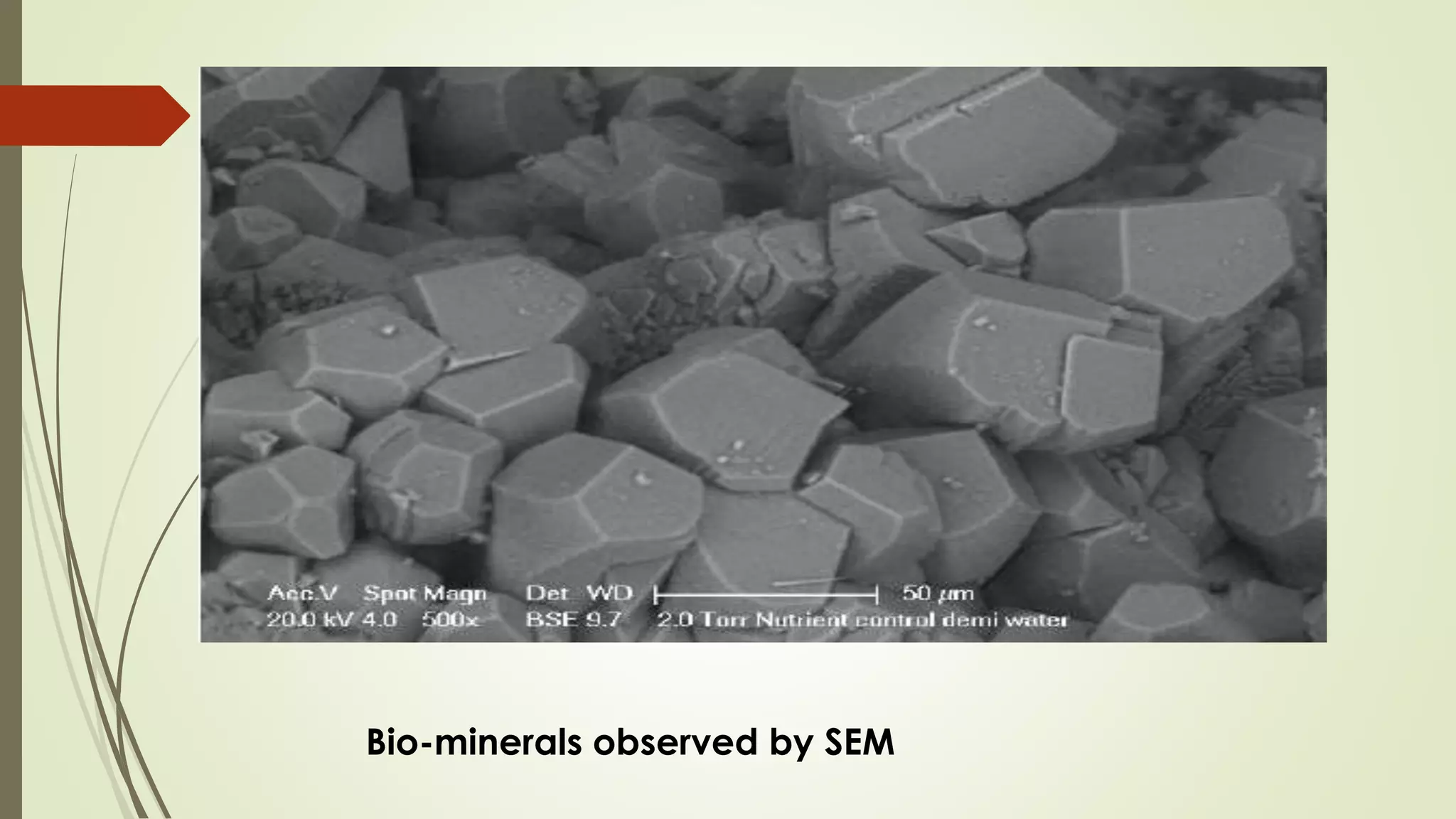

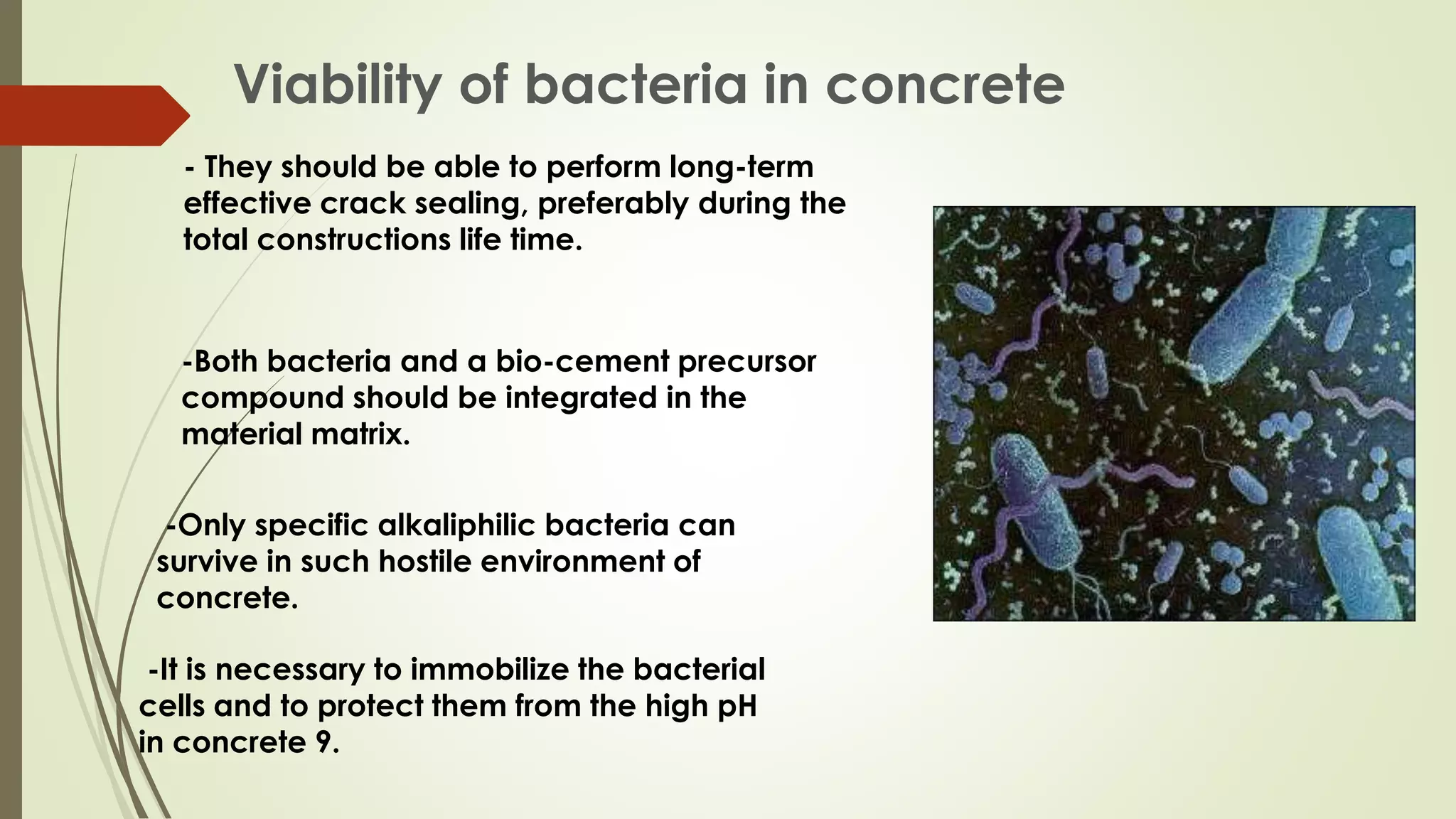

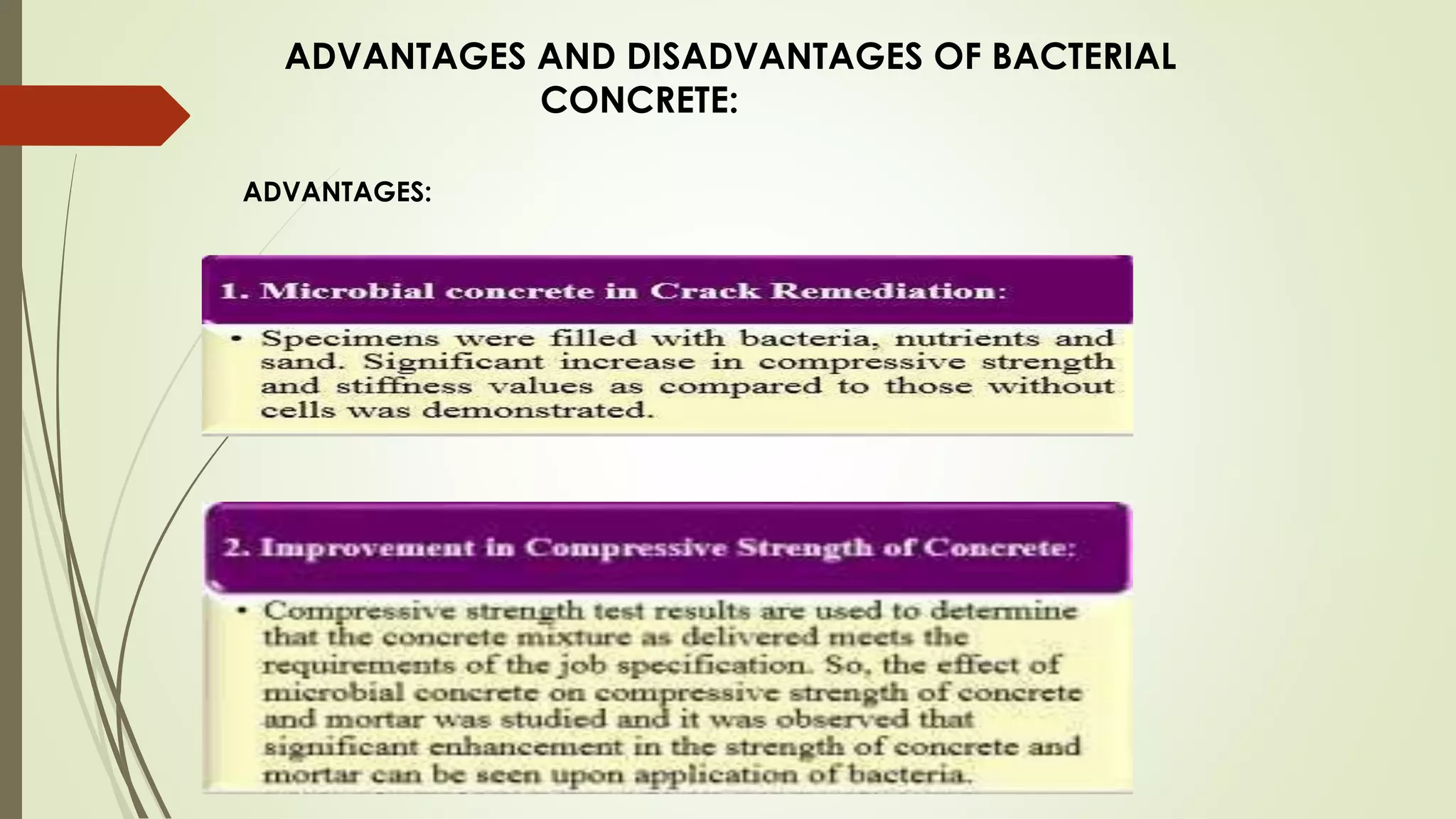

Bacteria-based self-healing concrete uses dormant calcium-precipitating bacteria encapsulated during mixing. When cracks form and water enters, the bacteria activate, metabolize nutrients, and precipitate calcium carbonate to seal cracks. Testing shows bacterial concrete has higher strength and crack-healing ability compared to normal concrete. While increasing durability, applications in construction could lower costs and improve sustainability over time. Further research is still needed to optimize the technology for practical and economic feasibility at scale.