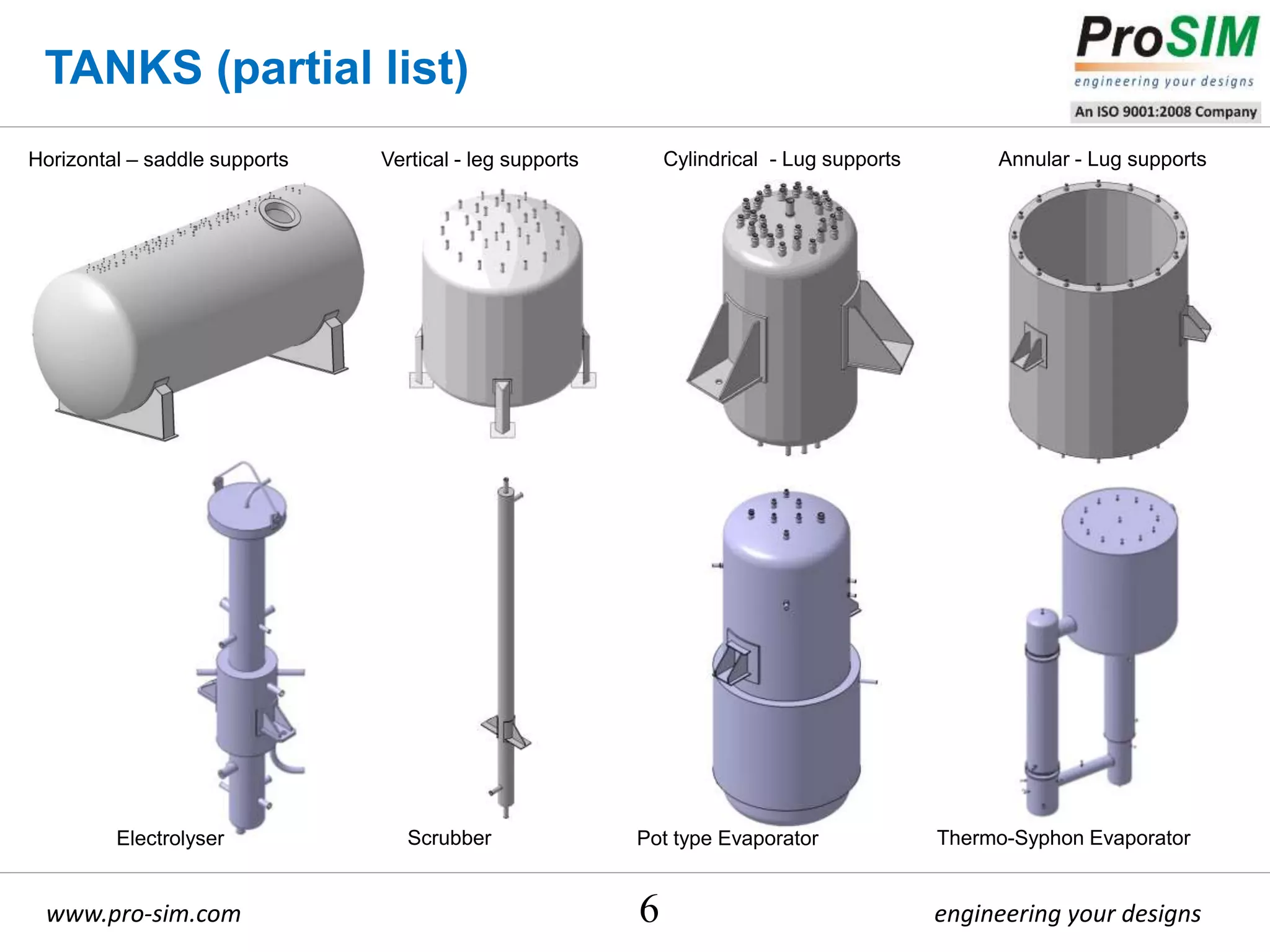

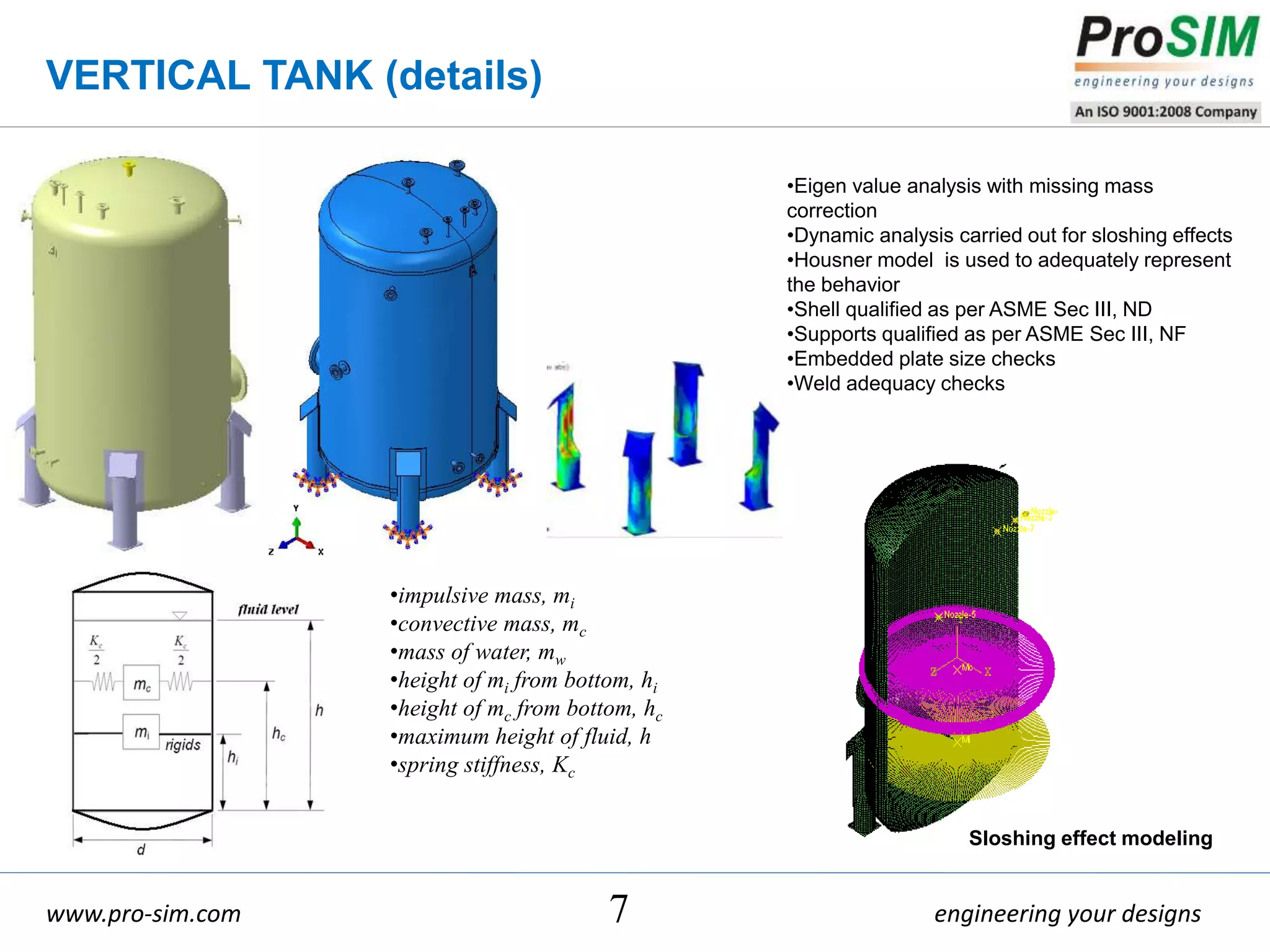

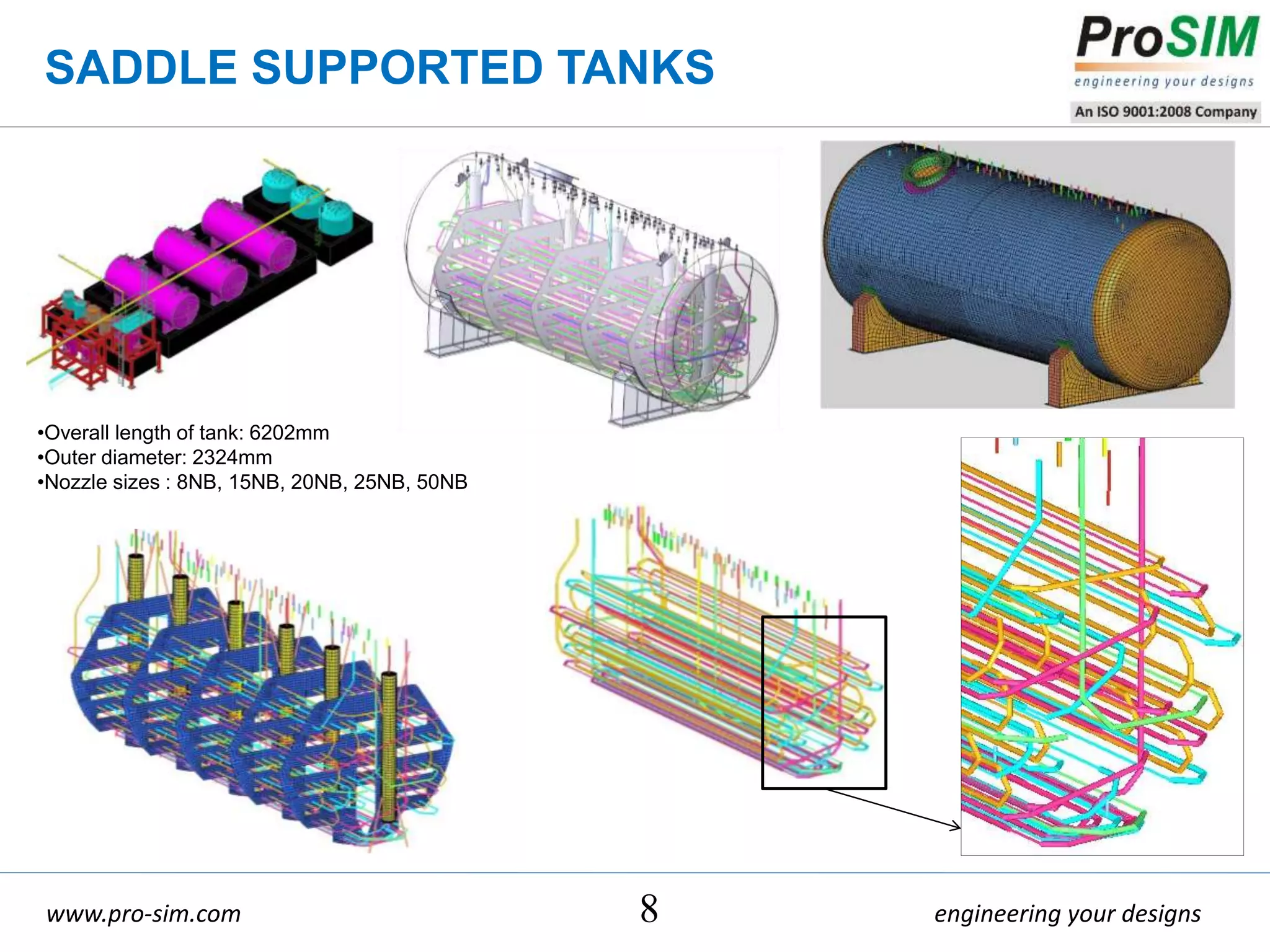

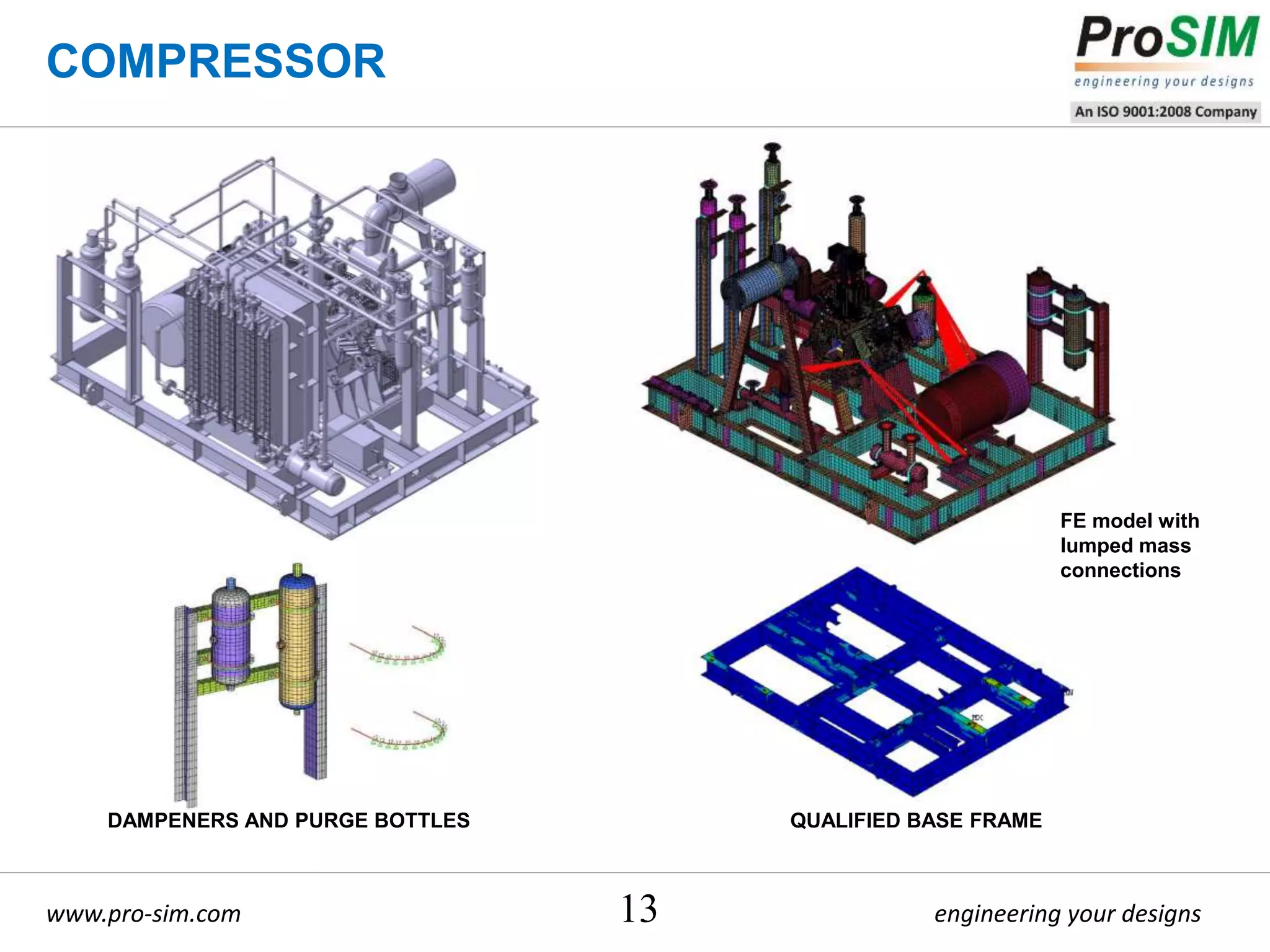

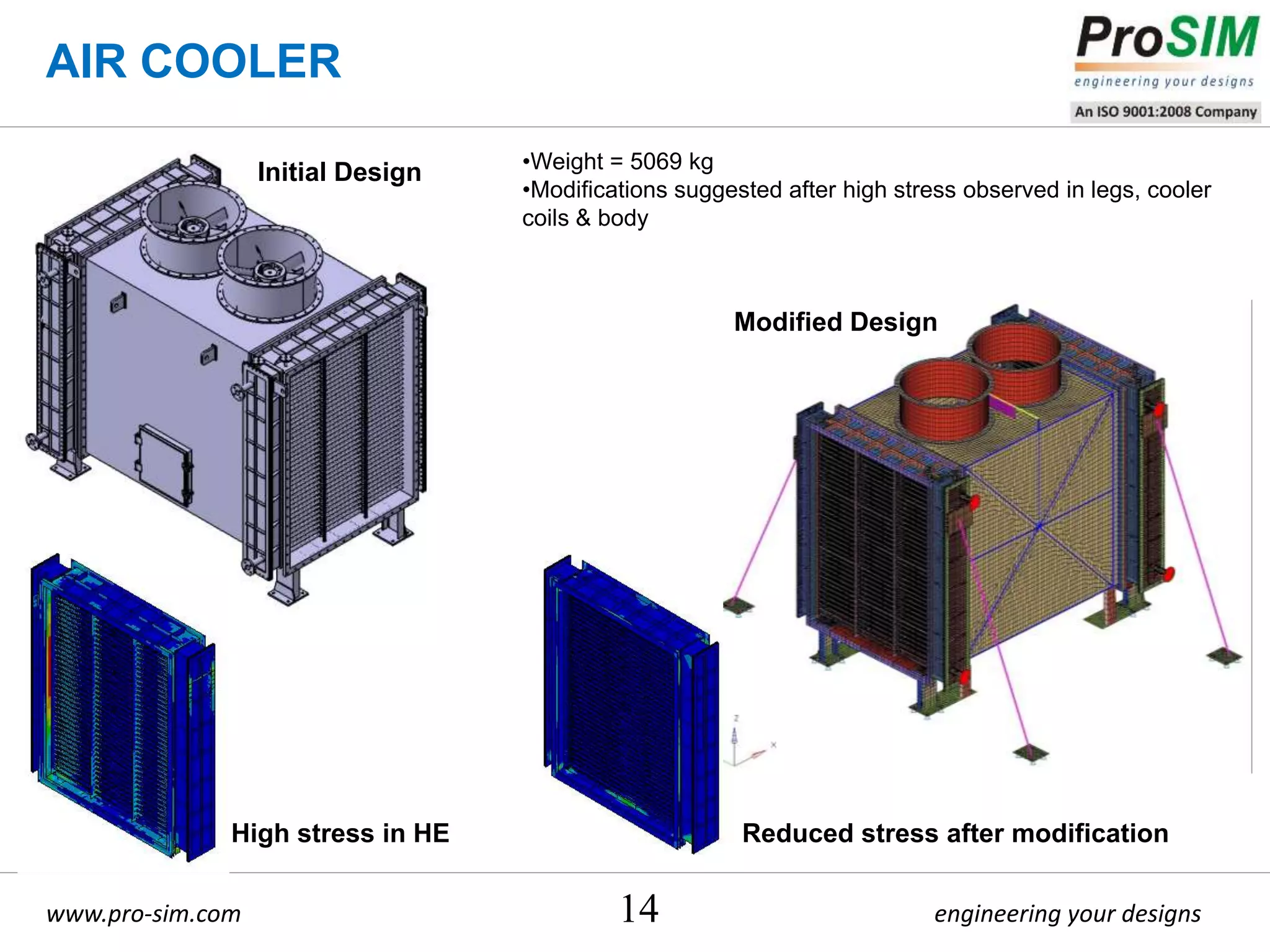

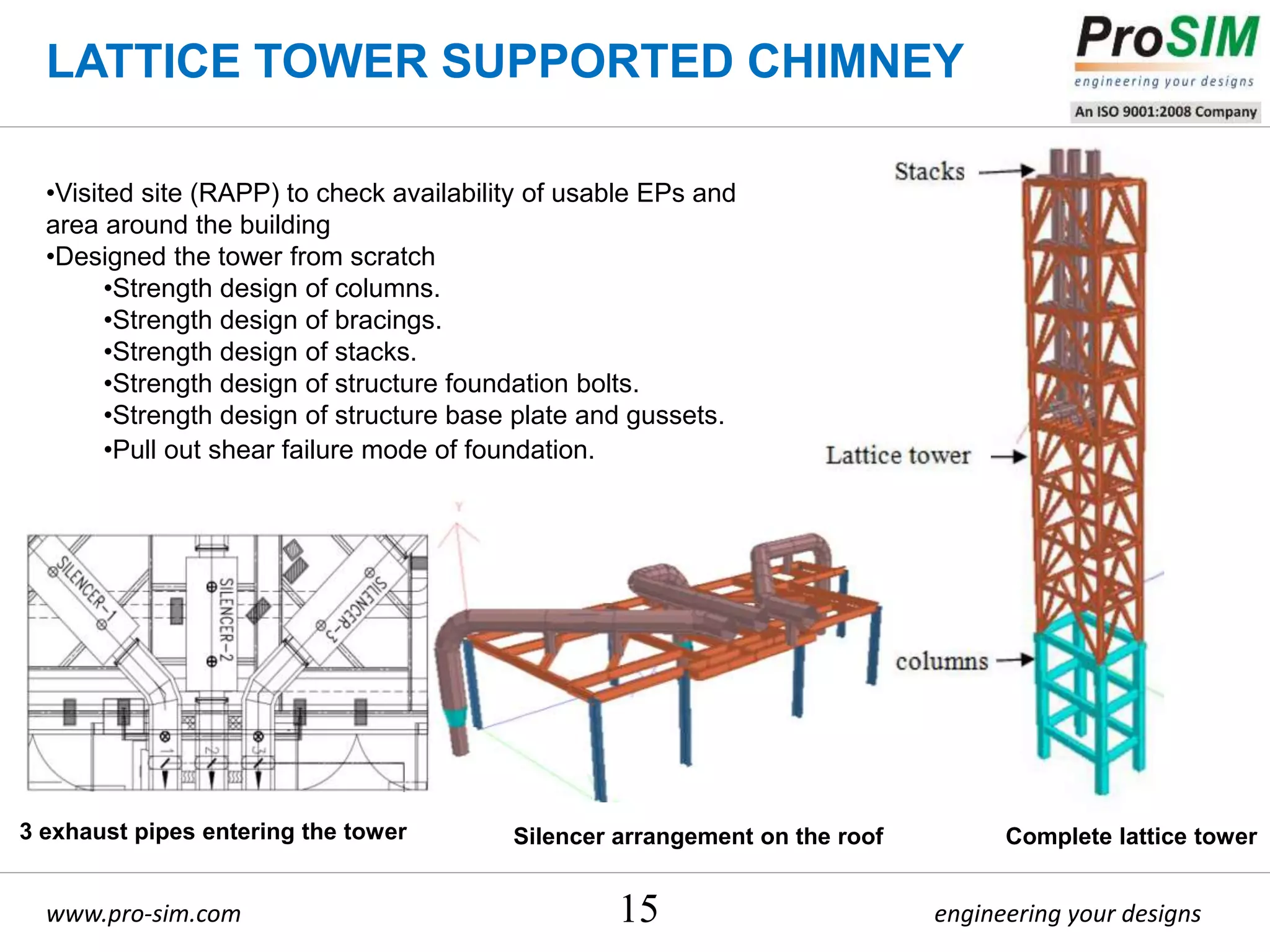

ProSim is a qualified seismic consultant for equipment in nuclear power plants, with over 40 executed projects involving mechanical and electrical equipment qualification under seismic conditions. Their expertise includes using FEA codes like ANSYS and ABAQUS, and they offer complete responsibility from seismic methodology development to documentation and technical support. ProSim's services encompass a wide range of equipment including tanks, valves, control systems, and special structures.