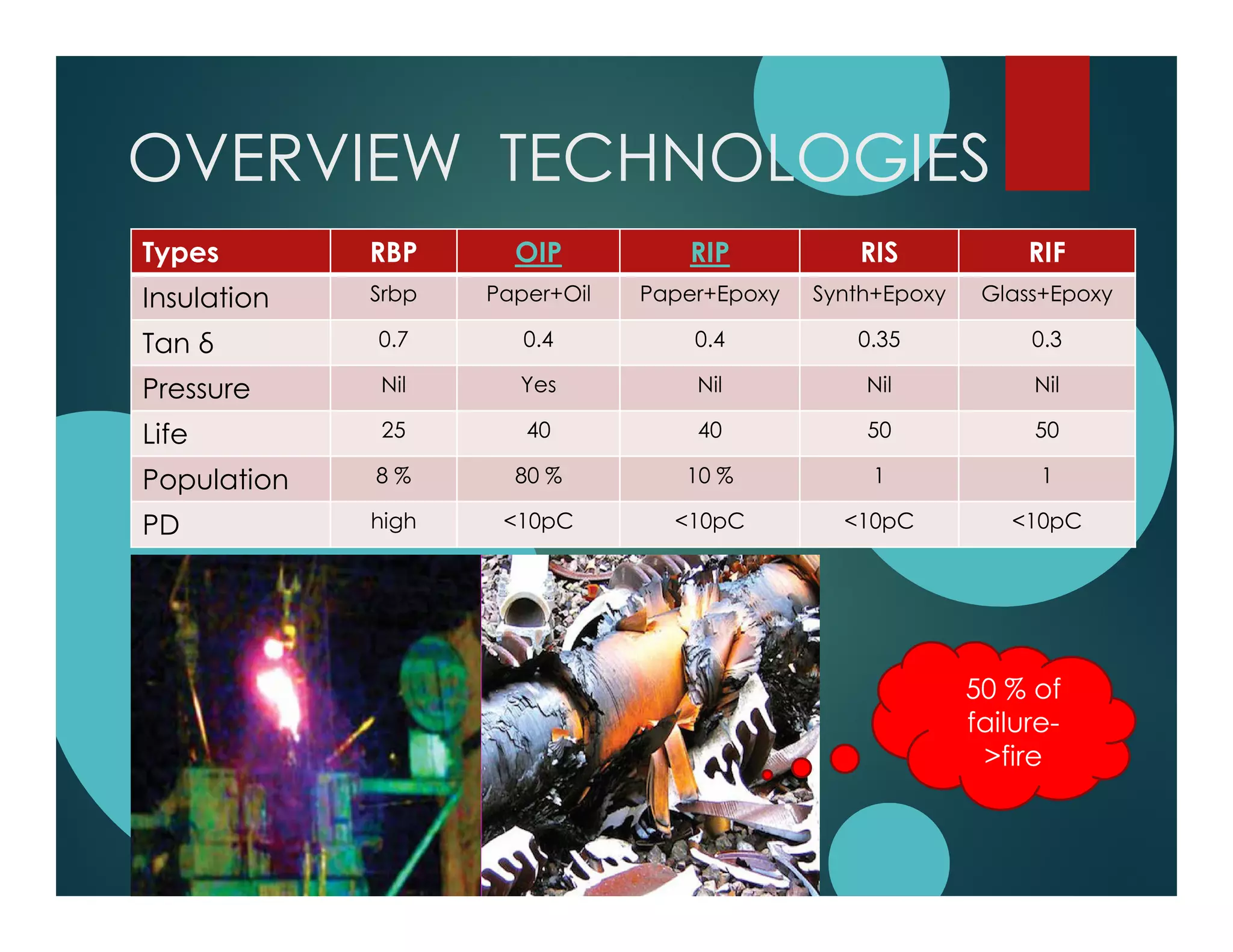

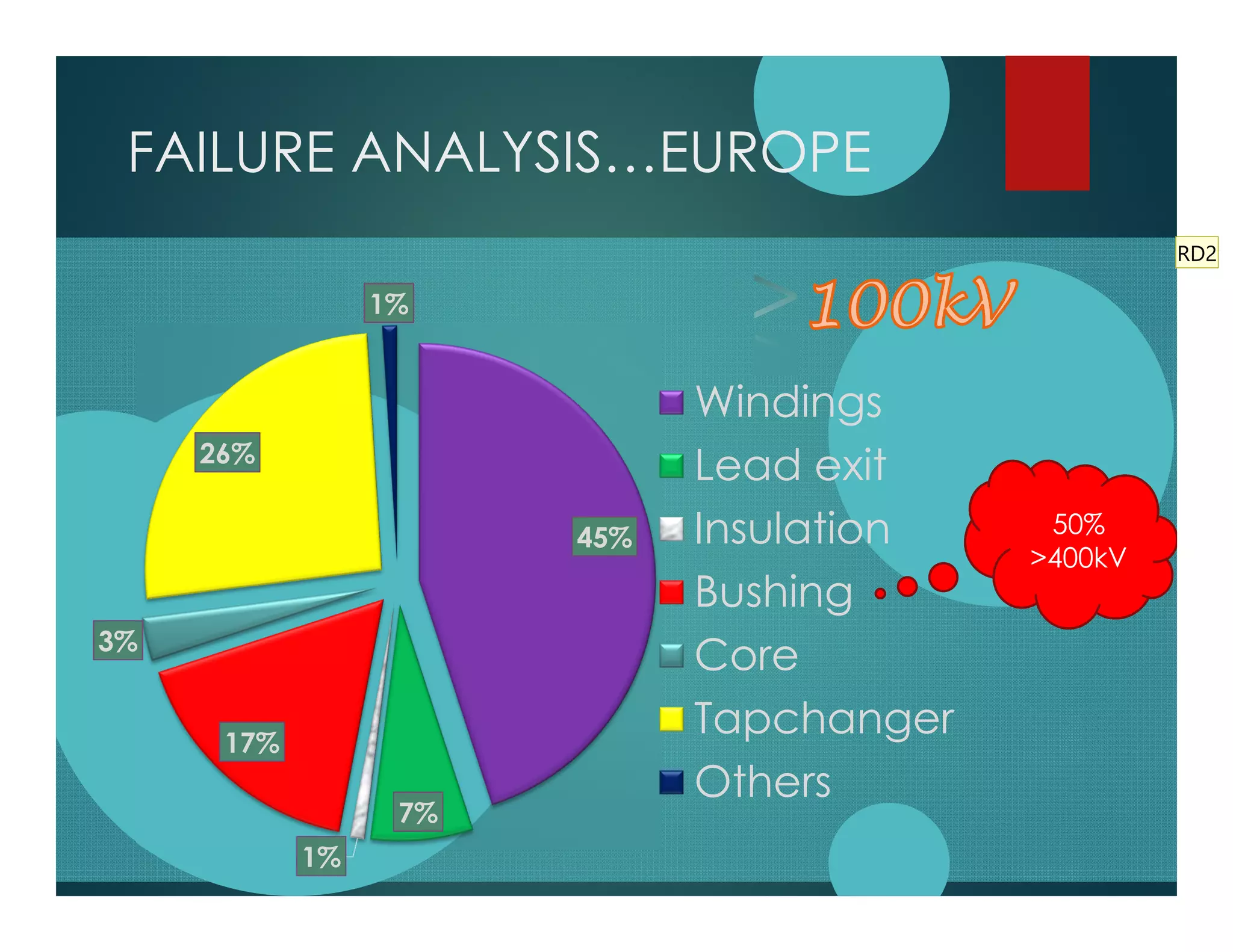

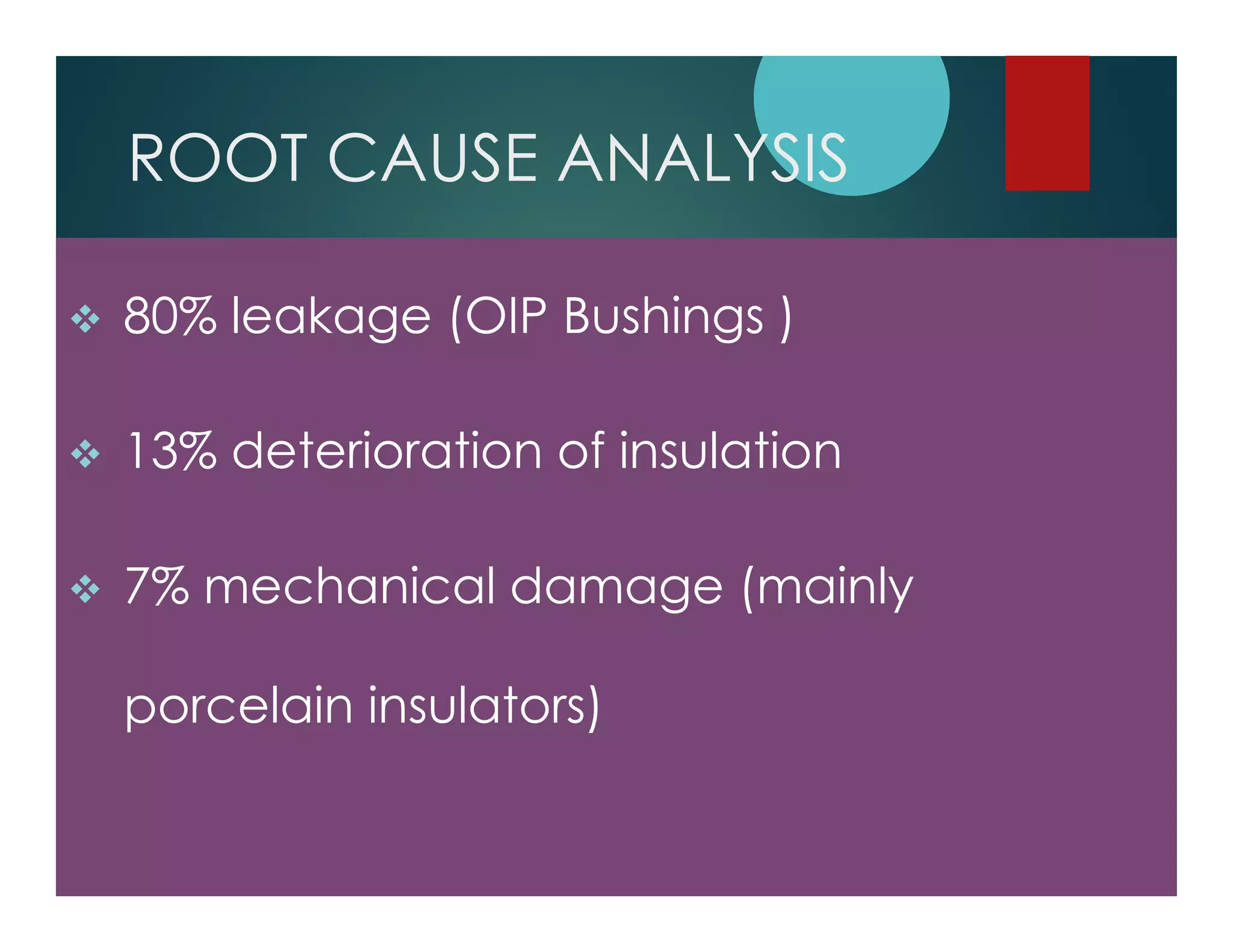

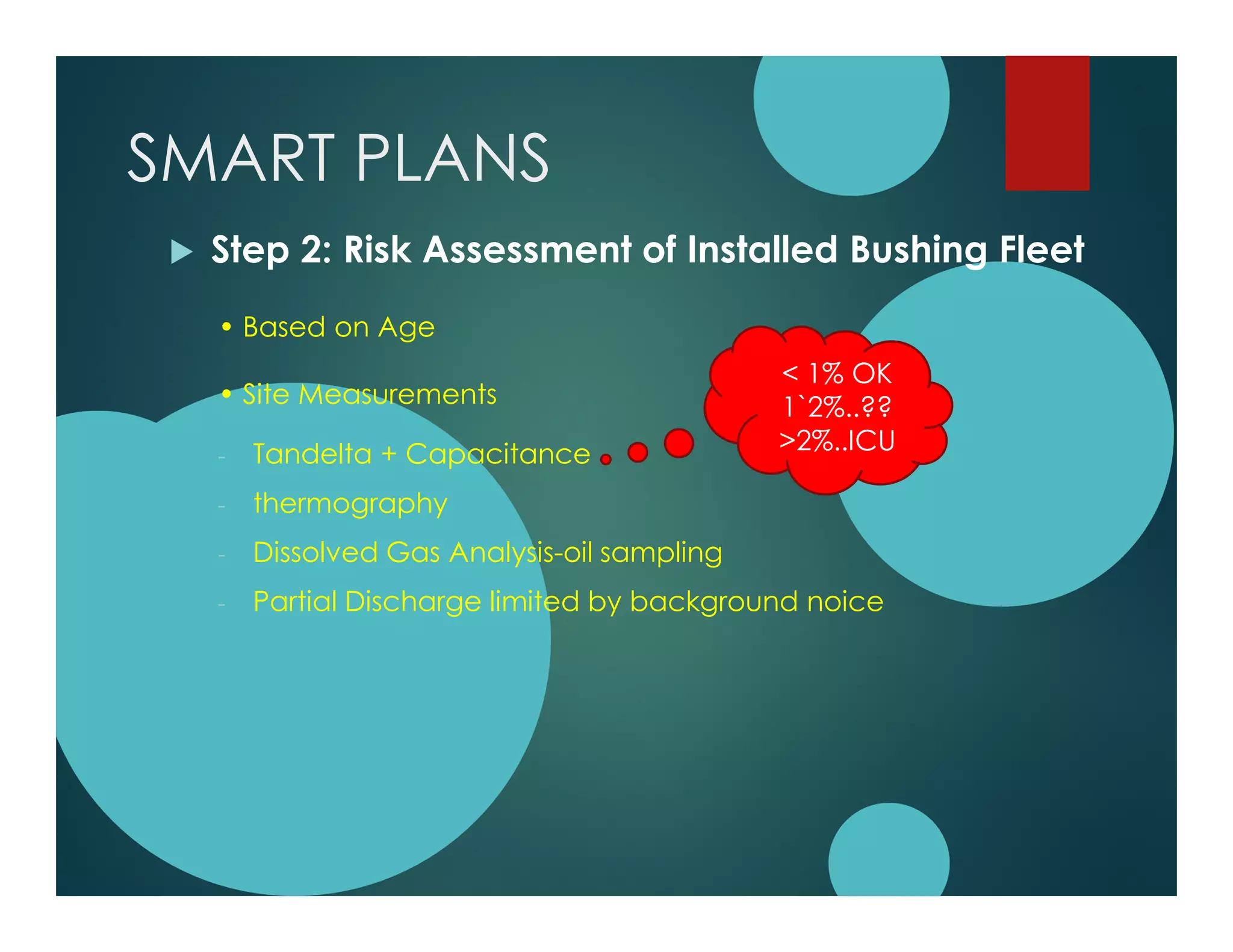

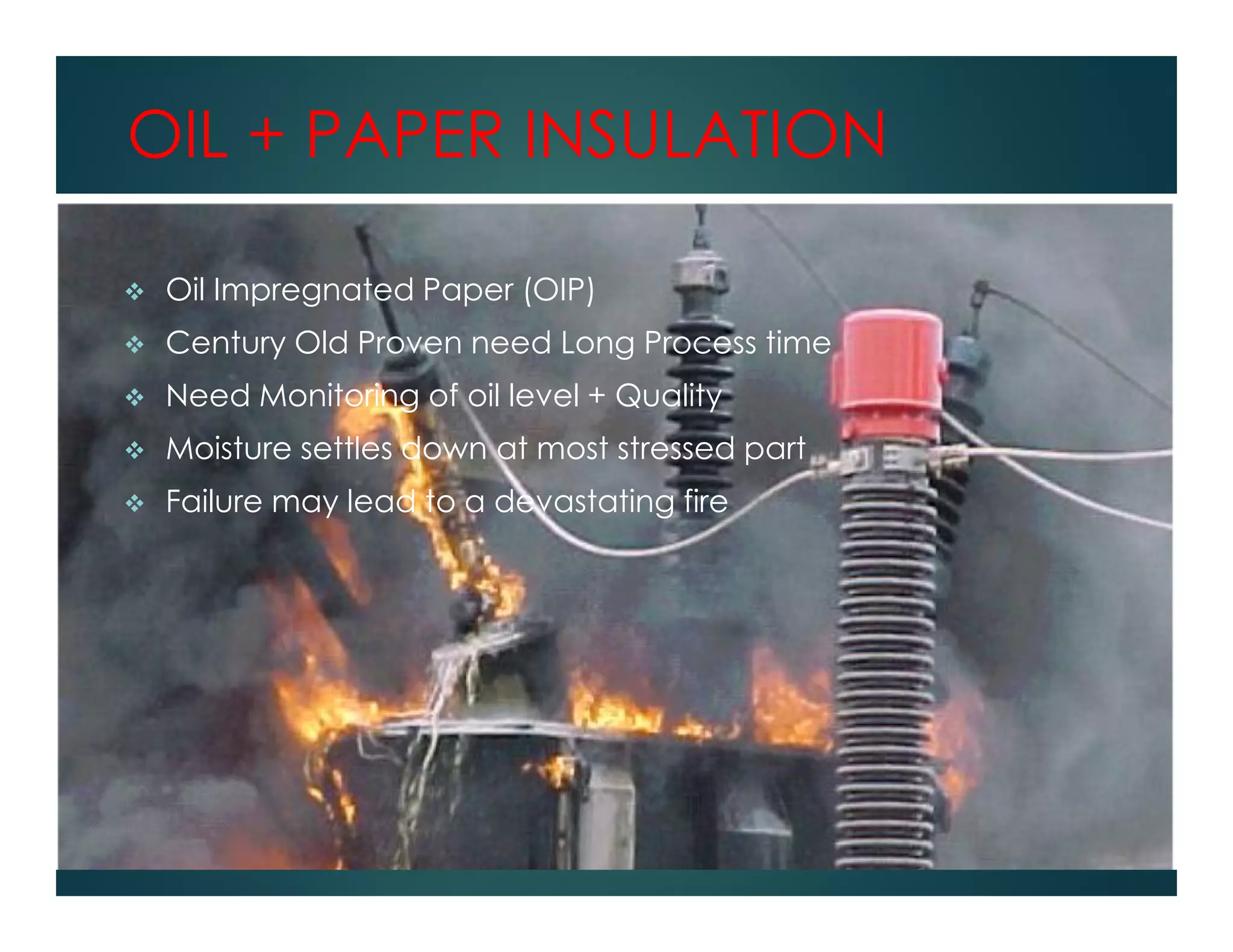

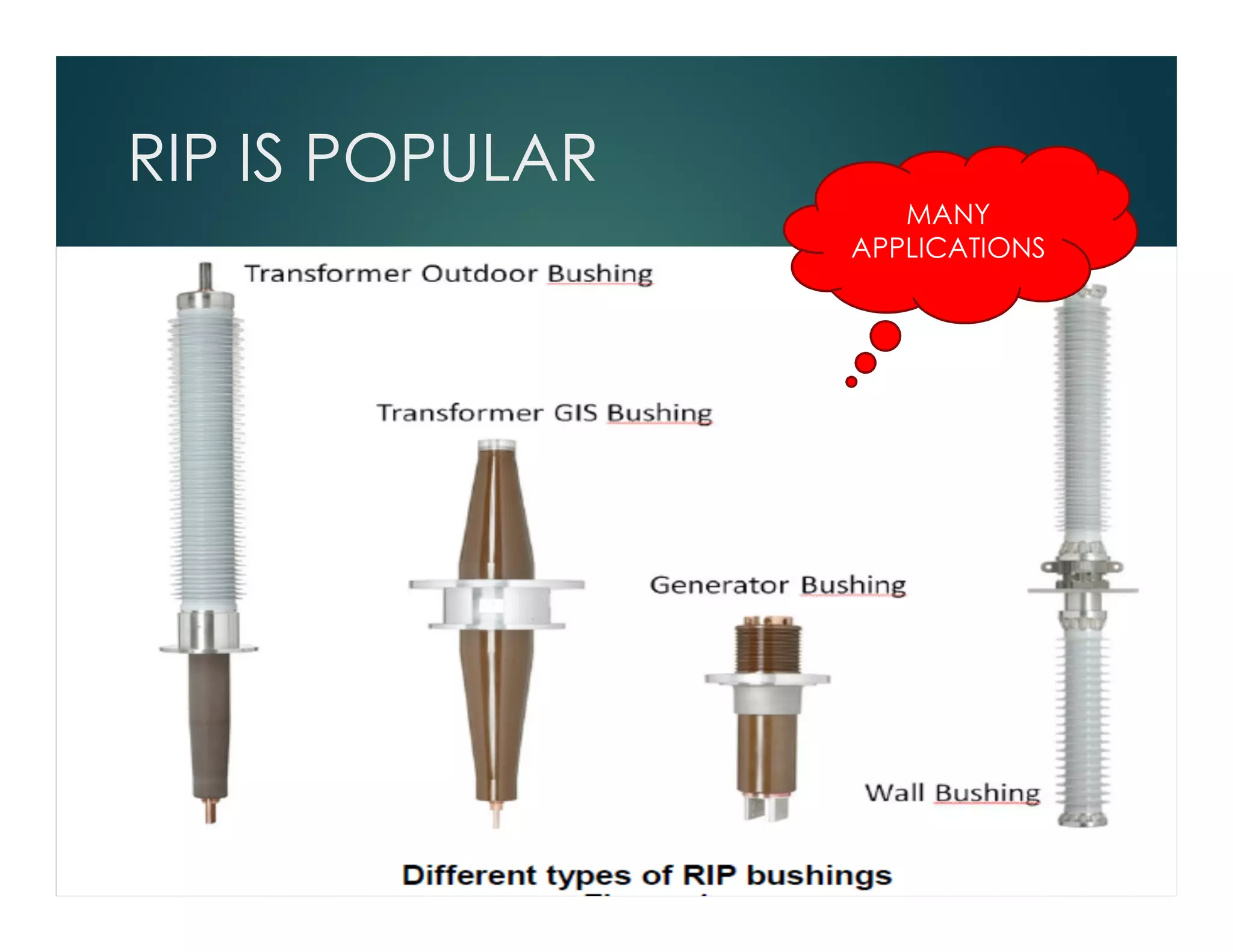

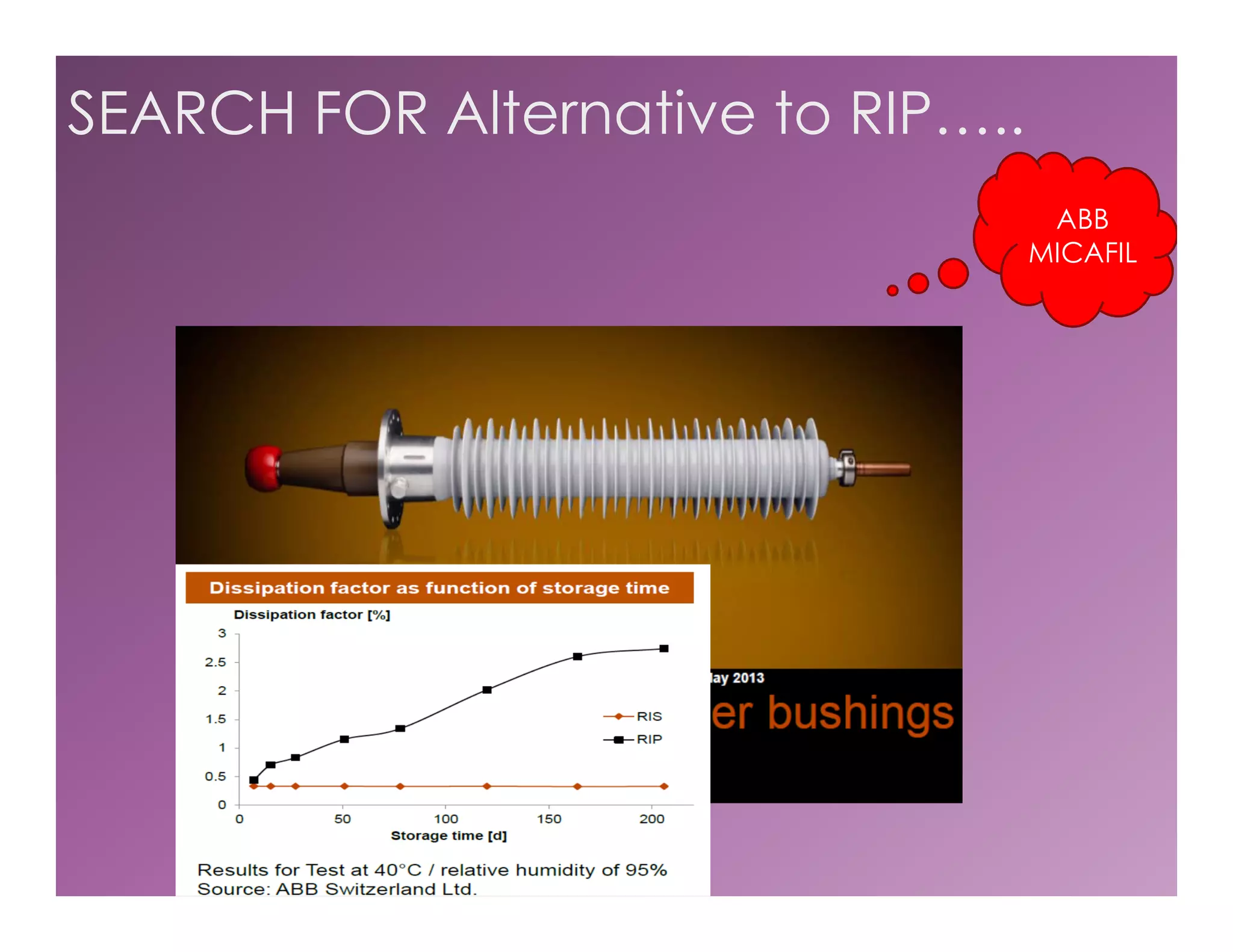

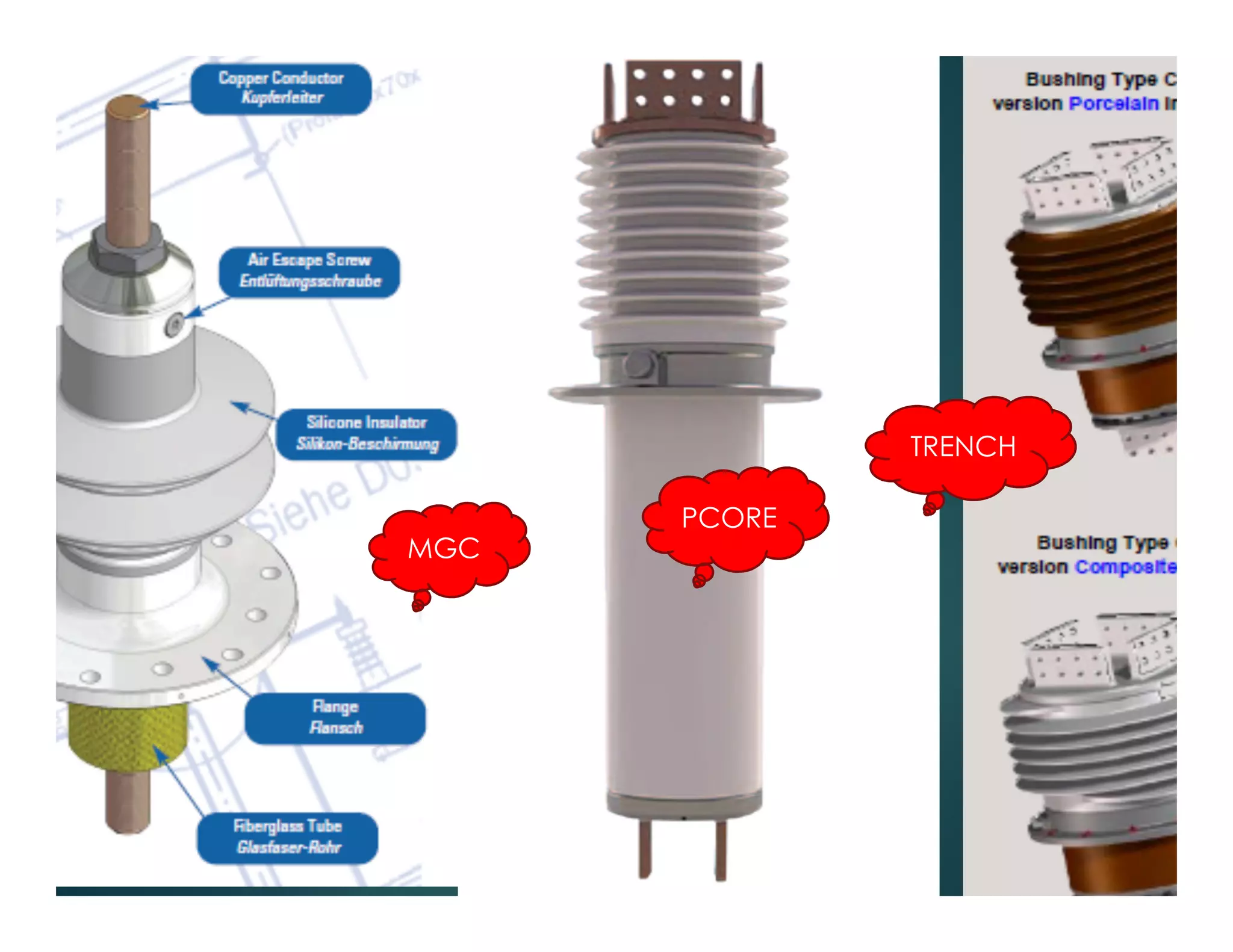

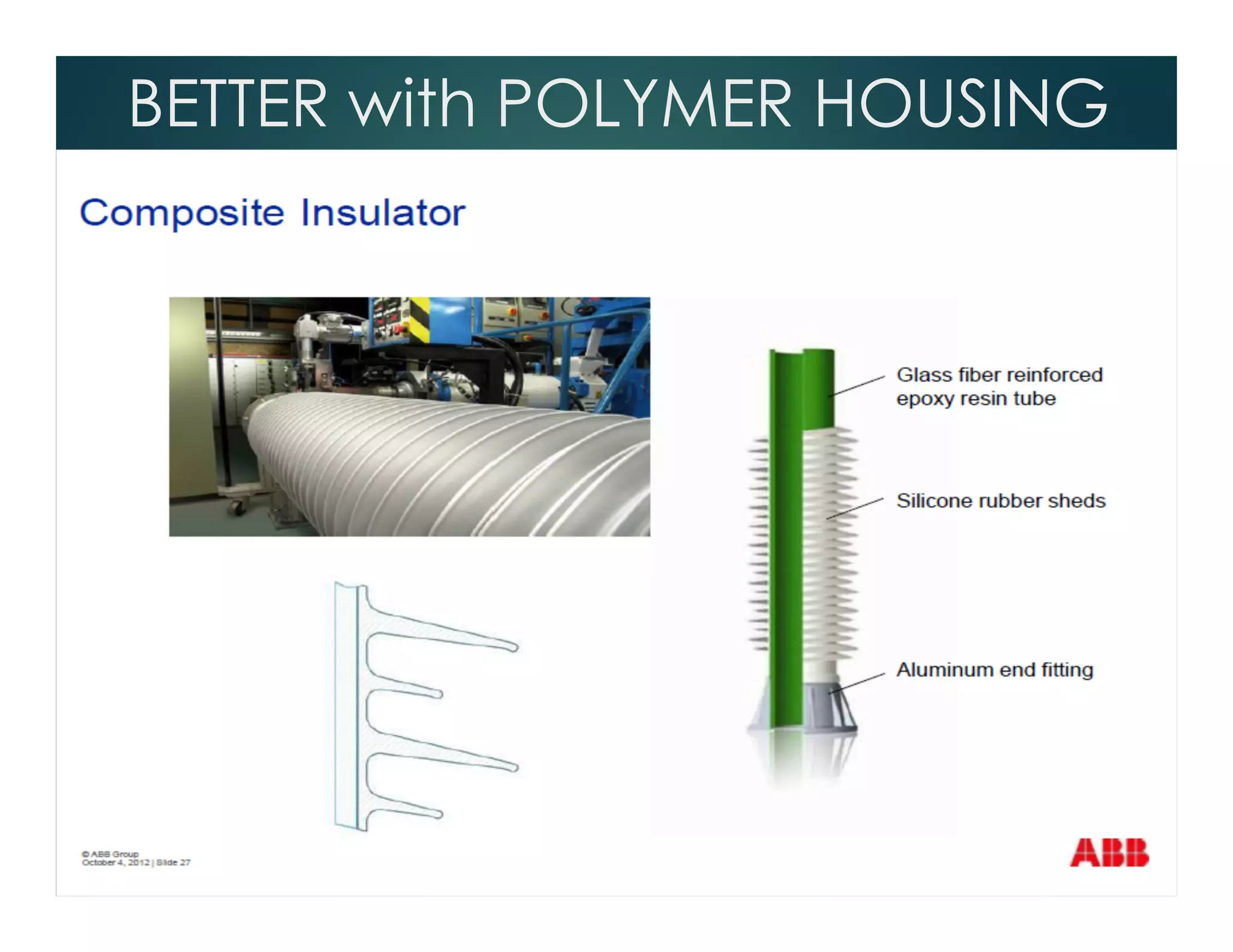

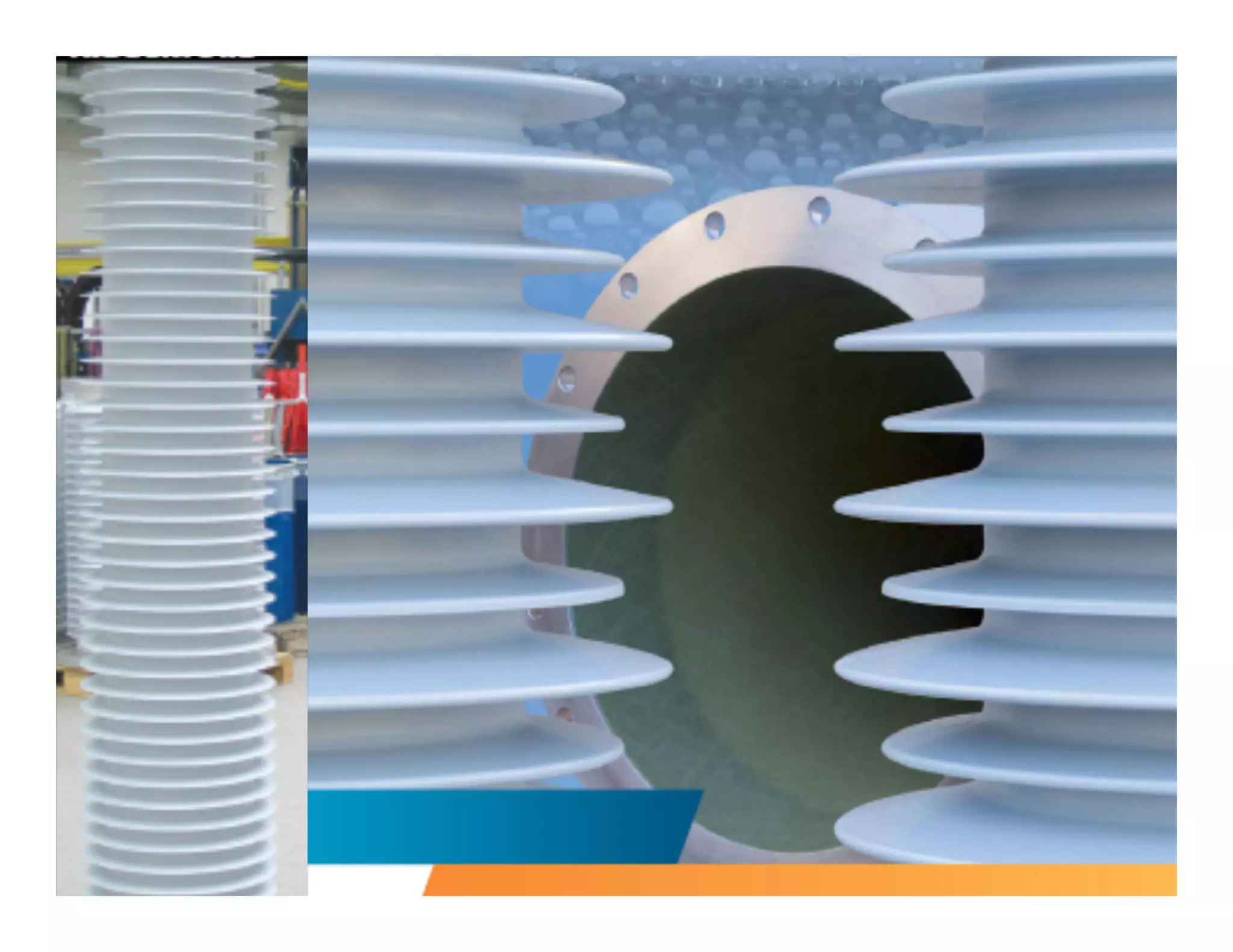

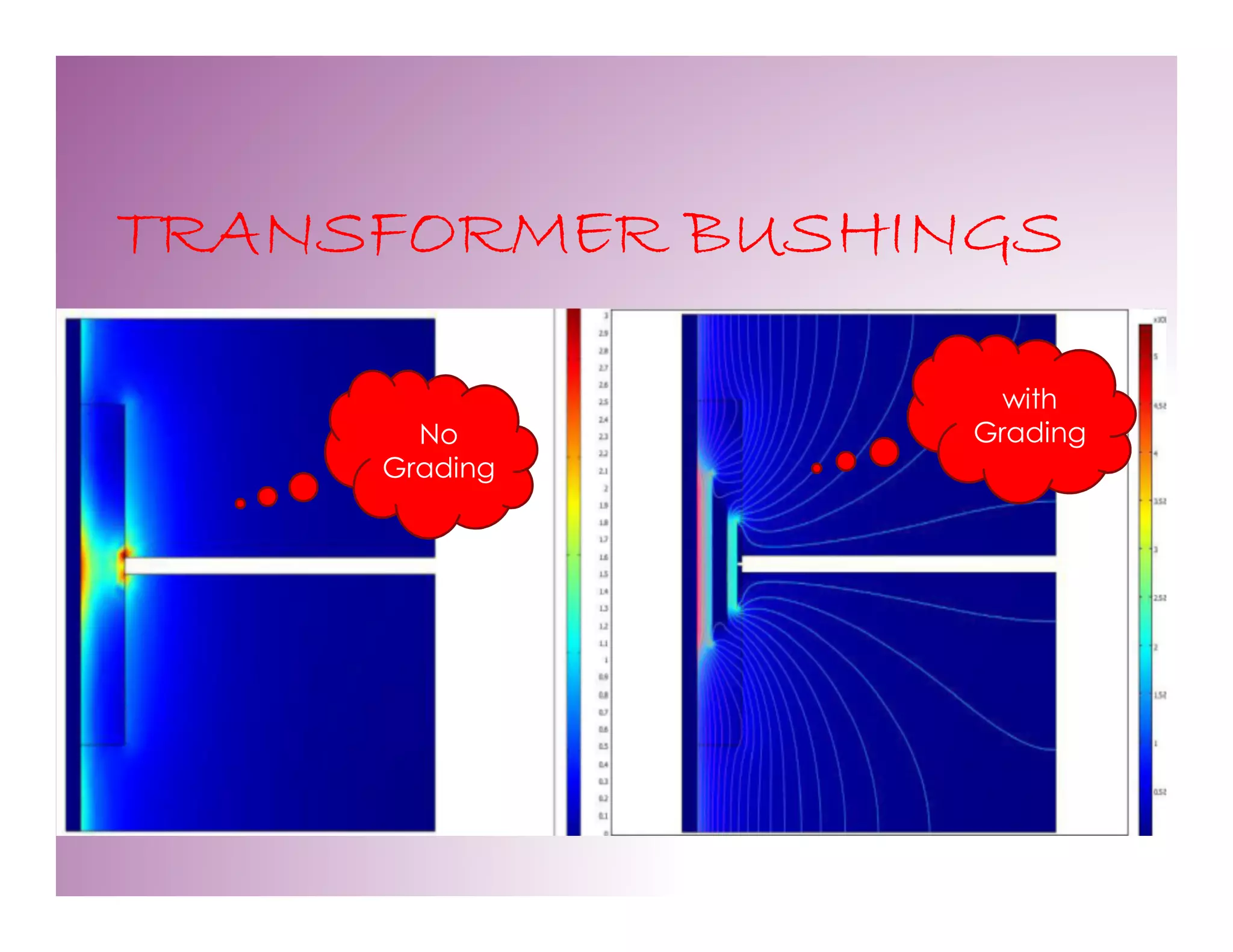

The document reviews various bushing technologies for transformers, focusing on improving reliability and safety through risk assessment and innovative materials. It discusses the advantages of resin impregnated paper (RIP) and highlights alternatives like fiberglass impregnated glass, offering greater resistance to mechanical and thermal stresses. The document outlines a step-by-step smart plan for replacing aging bushing fleets based on risk factors and technology types.