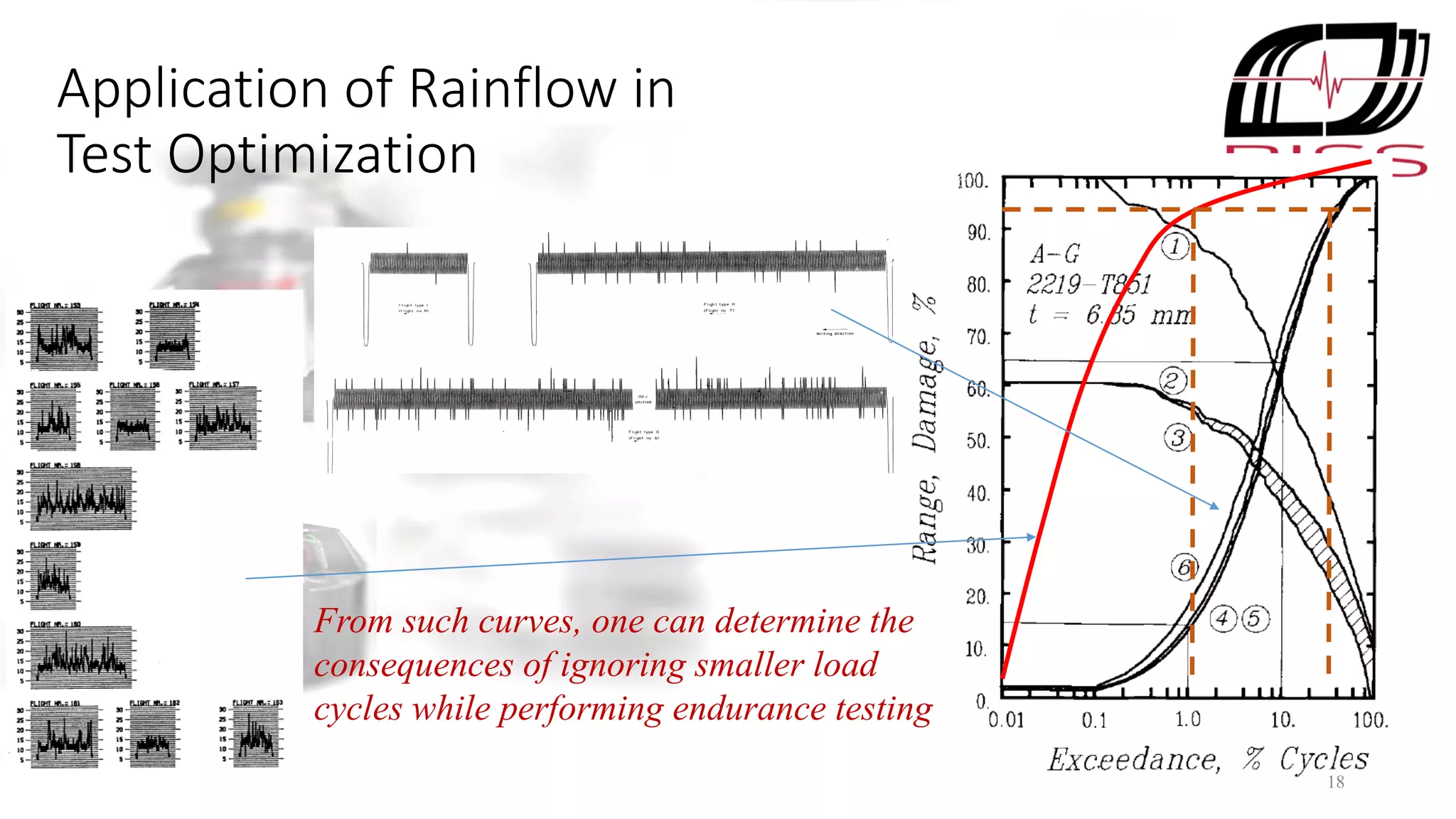

This document discusses fatigue analysis and fracture mechanics in engineering. It provides an overview of BiSS operations in testing services and collaborations in various industries. It then summarizes that fatigue analysis involves accounting for variable load amplitudes and stresses through methods like rainflow cycle counting. Fracture mechanics characterizes crack stresses using stress intensity factors determined from geometry and materials toughness testing. Finally, it emphasizes that structural integrity assurance requires considering long-term material behavior under service loads to ensure safe and economical operations over a structure's lifetime.

![Innovating to simplify!

Simulation Works….

Early work by Jhansale [1978]

1

1

2

4

3

5

e

s

2

3

4

5

'/1

'

n

KE

ss

e](https://image.slidesharecdn.com/fracturemechanicsstructuralintegritymumbaimay102018-180528105917/75/Fracture-mechanics-amp_Sundar-R-11-2048.jpg)