The presentation covered various topics related to solid-liquid mixing including:

- The definitions and goals of mixing to reduce non-uniformities and obtain a uniform mixture.

- The different types of mixing like solid-solid, liquid-liquid, and solid-liquid mixing.

- Factors that influence mixing like particle size and shape, moisture content, and mixer efficiency.

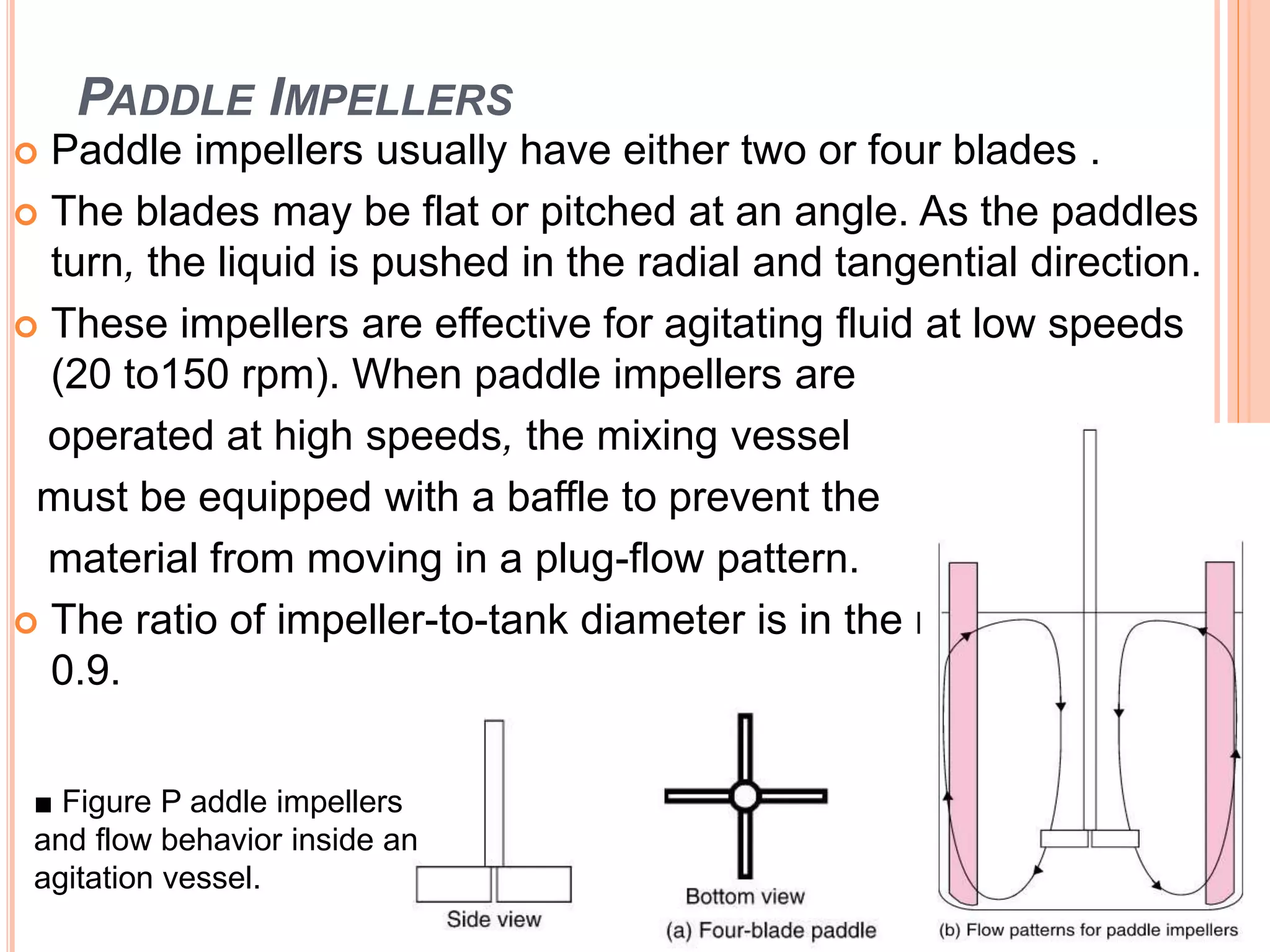

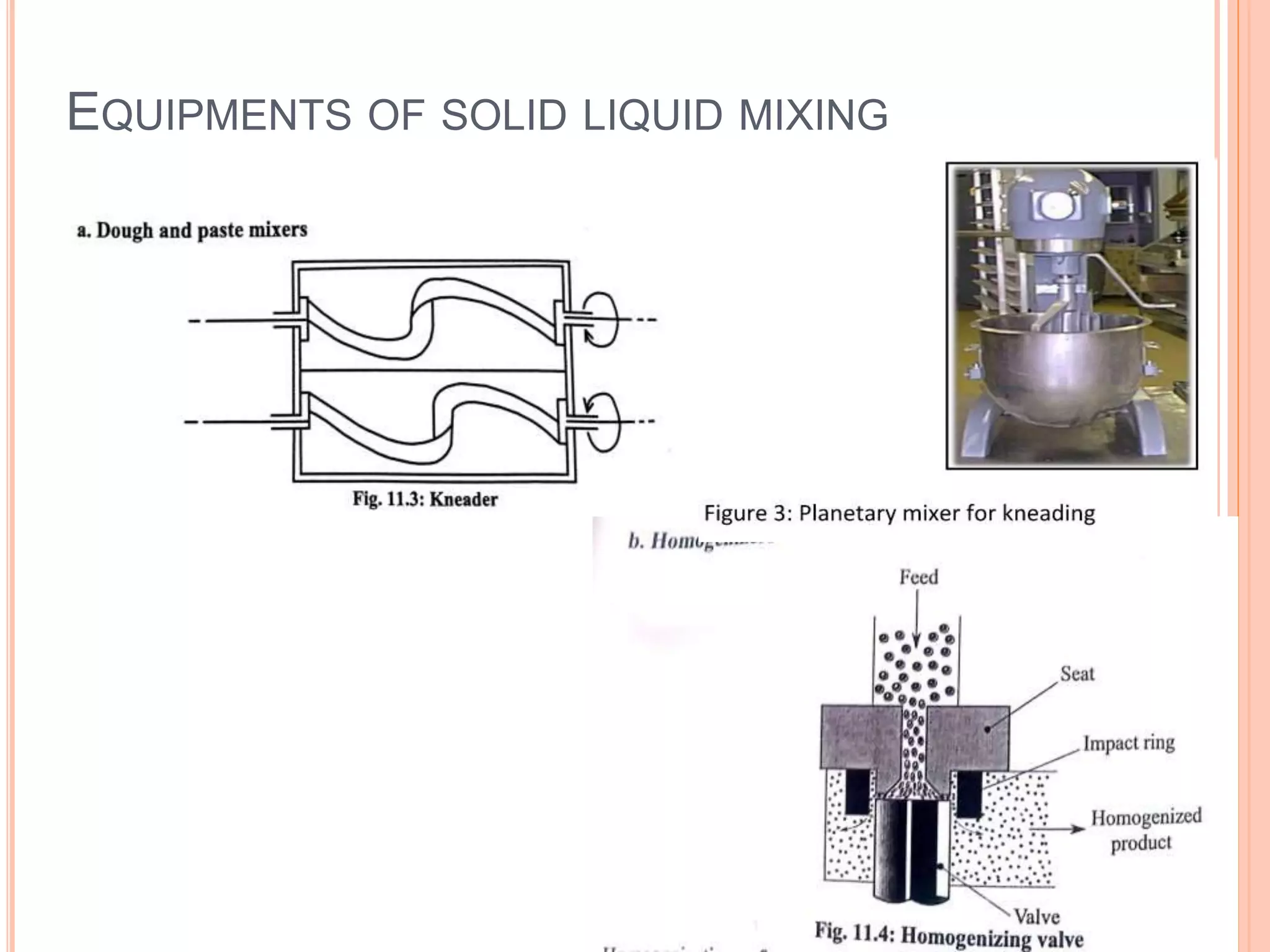

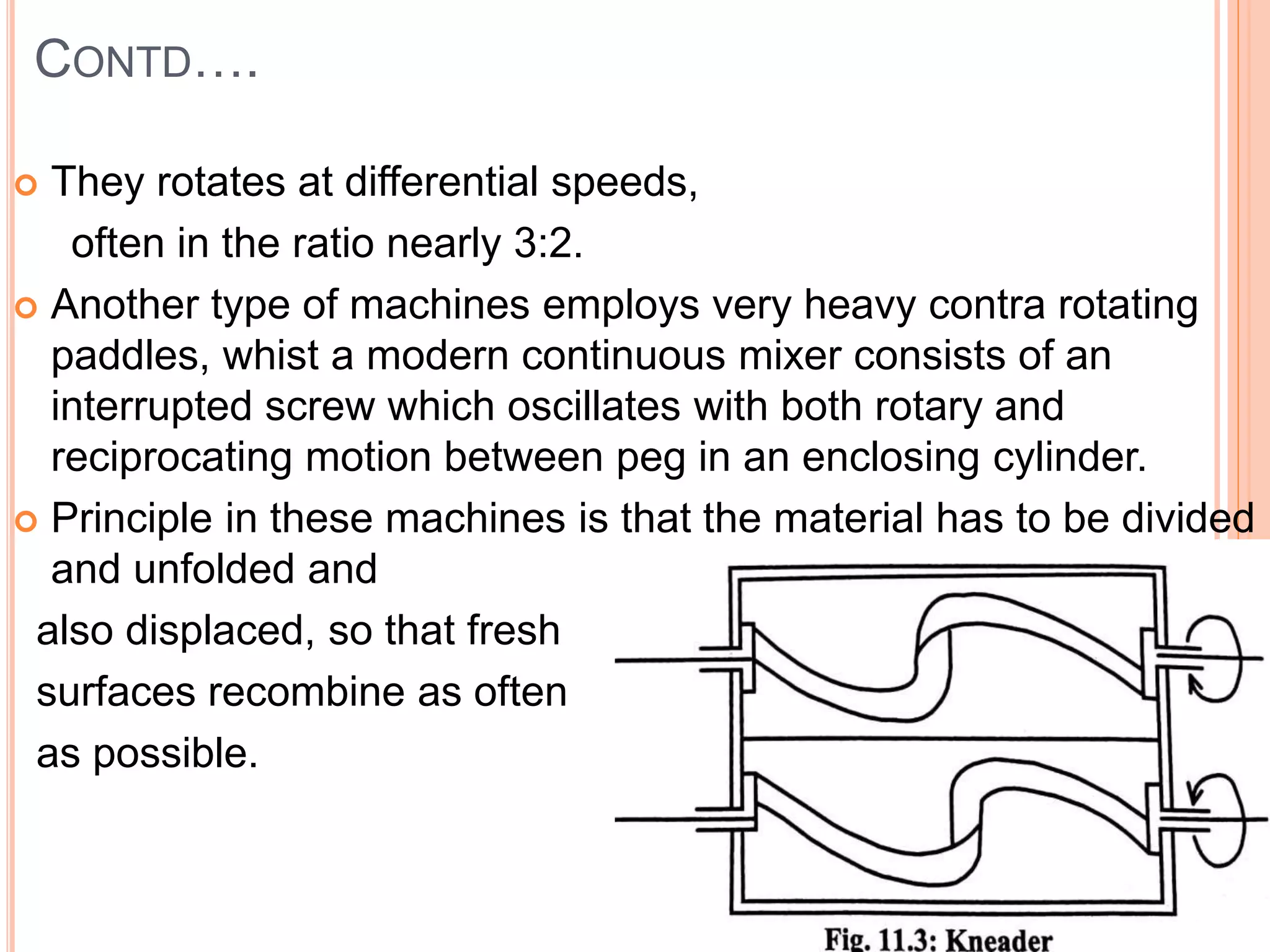

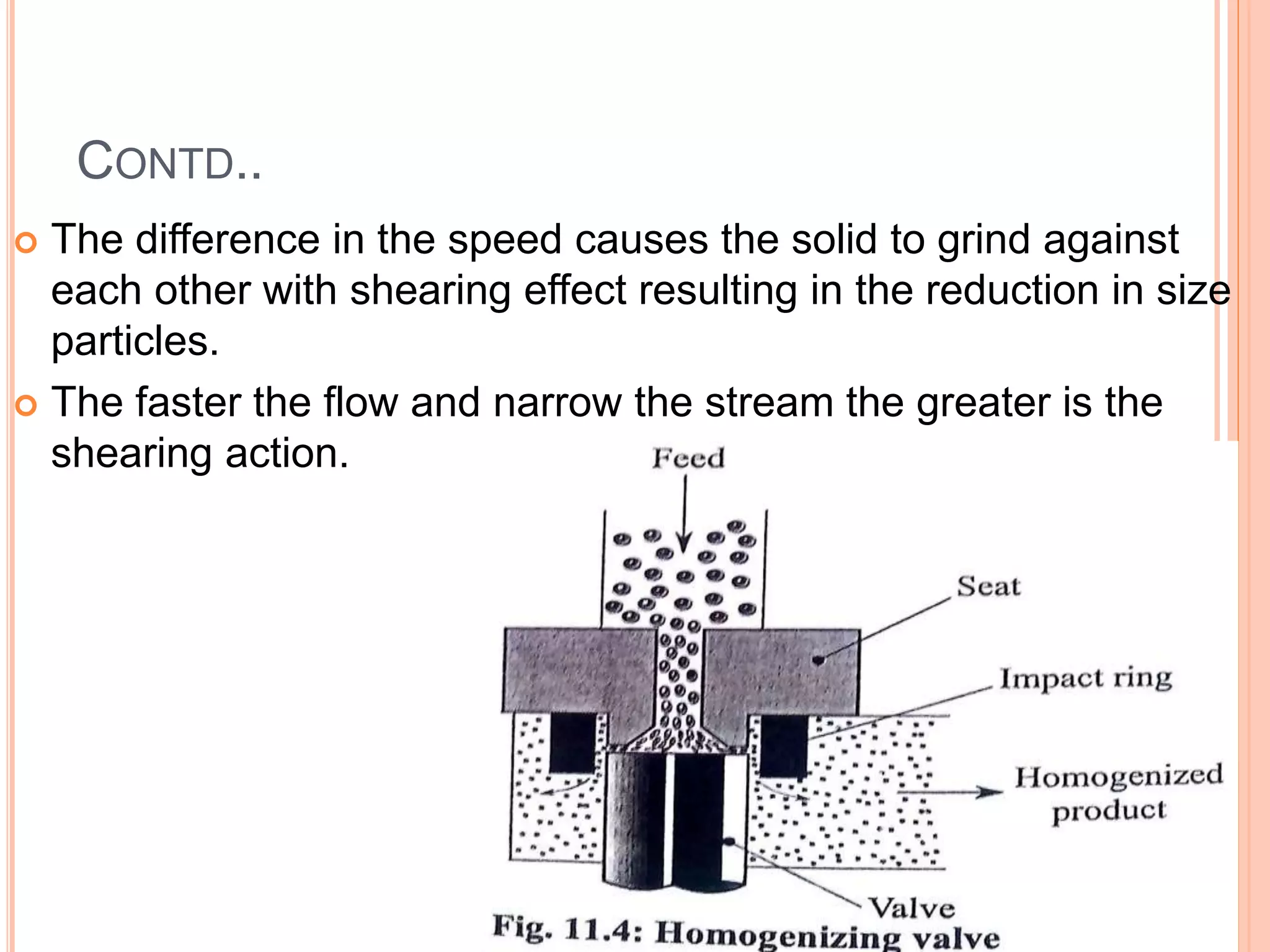

- Equipment used for mixing like kneaders, homogenizers, and paddle or propeller impellers.

- Applications of mixing in food and other industries like chemicals, polymers, cosmetics, and more.