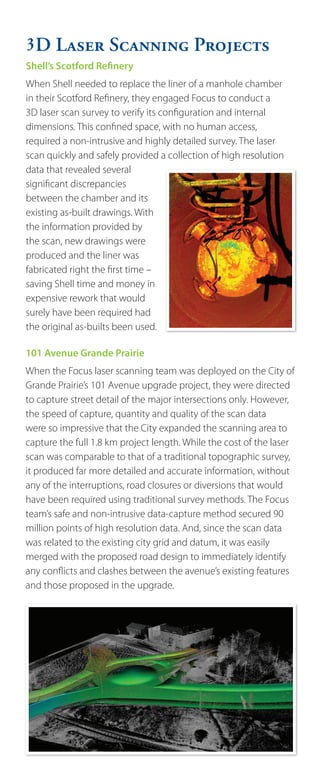

3D laser scanning uses lasers to quickly and safely collect large amounts of detailed data on structures and locations that would be difficult or dangerous to survey with traditional methods. Laser scanning provides highly accurate measurements and captures unprecedented detail of piping, vessels, plants, roads and other infrastructure. It offers advantages over traditional surveying by lowering costs, reducing need for return visits, enabling pre-fabrication to avoid construction issues, and minimizing downtime. Laser scanning was used on projects for Shell's refinery and a city road upgrade, accurately documenting configurations, detecting discrepancies, and identifying conflicts to support fabrication and design within budget and schedule.